Devising measures to reduce multi-frequency noise load on employees in machining area

DOI:

https://doi.org/10.15587/1729-4061.2024.306725Keywords:

occupational safety, noise source, working area, noise load, soundproof barrierAbstract

The object of this study is the process of determining and managing the risks of noise exposure (NE) for employees at the mechanical department when machining metals on a drilling machine (DM).

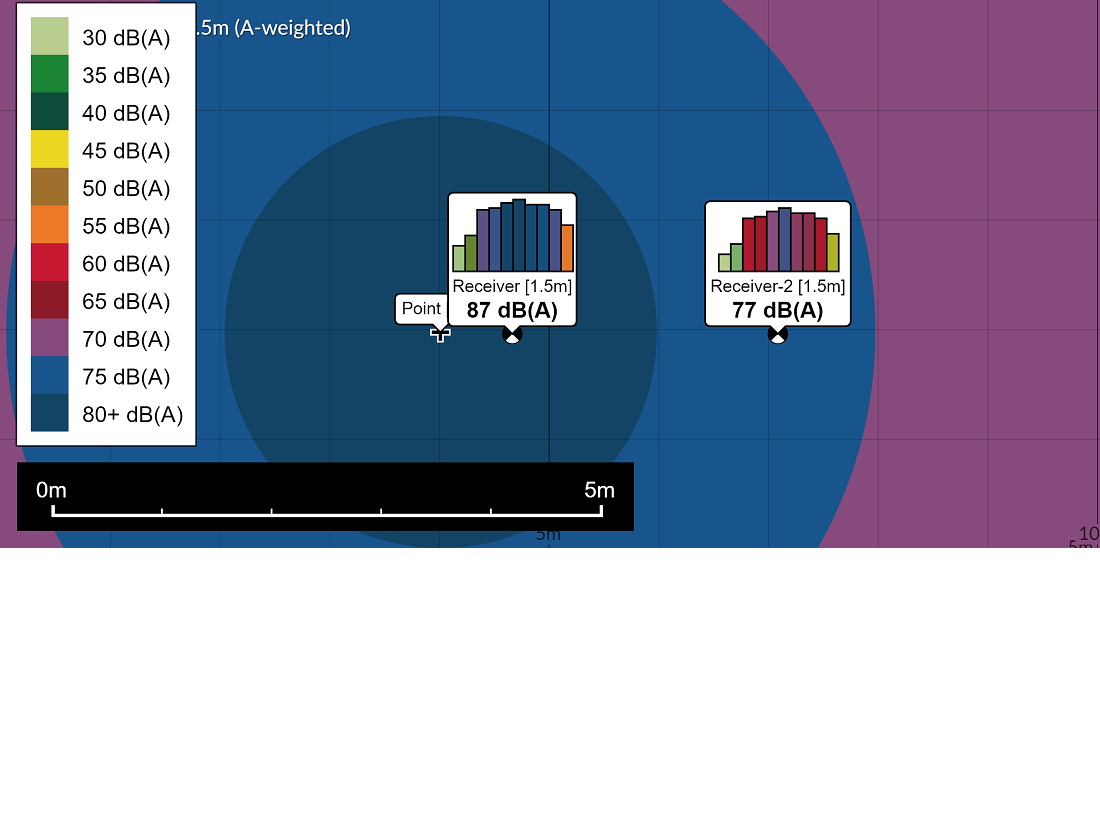

The problem relates to the increase in the risk of an employee receiving an industrial injury because of NE at the workplace of a machine tool. The impact of noise on the human body depends on the duration of exposure, the level of sound pressure, and its intensity. An important characteristic of noise is its frequency composition, as it can affect the perception of sounds and the human body. Prolonged exposure to noise can damage various systems in the human body or cause pain. Therefore, it is important to understand the impact of NE on workers and devise measures to reduce the negative impact on their health and work productivity. The research is based on real-time noise measurements followed by their decomposition into octave frequencies and modeling of noise propagation in the room with and without the use of various types and designs of soundproof barriers (SB). In the course of the study of NE propagation during drilling on the machine, an excess of noise levels at medium and high frequencies near the noise source was found. An employee who works on DM is exposed to high-frequency noise that exceeds the established normative indicators. Therefore, it is necessary to use personal protective equipment for the machine operator and install safety equipment to protect other workplaces. The use of the latter makes it possible to significantly reduce the impact of NE on workers, in particular, at low frequencies by 20.8 %, at medium frequencies by 15.6 %, and at high frequencies by 17.3 %

References

- Pro otsinku vplyvu shumu na navkolyshnie seredovyshche: Dyrektyva Yevropeiskoho Parlamentu ta Rady vid 25.06.2002 r. No. 2002/49/YeS. Official Journal. L. 189. 18.07.2002. P. 0001–0004.

- Wegener, K., Bleicher, F., Heisel, U., Hoffmeister, H.-W., Möhring, H.-C. (2021). Noise and vibrations in machine tools. CIRP Annals, 70 (2), 611–633. https://doi.org/10.1016/j.cirp.2021.05.010

- Rech, J., Dumont, F., Le Bot, A., Arrazola, P. J. (2017). Reduction of noise during milling operations. CIRP Journal of Manufacturing Science and Technology, 18, 39–44. https://doi.org/10.1016/j.cirpj.2016.09.001

- Haile, L. M., Kamenov, K., Briant, P. S., Orji, A. U., Steinmetz, J. D., Abdoli, A. et al. (2021). Hearing loss prevalence and years lived with disability, 1990–2019: findings from the Global Burden of Disease Study 2019. The Lancet, 397 (10278), 996–1009. https://doi.org/10.1016/s0140-6736(21)00516-x

- Rieznik, D. (2023). Experimental studies of noise pollution of mechanical processing plants. Journal of Donetsk Mining Institute, 2, 60–70. https://doi.org/10.31474/1999-981x-2023-2-60-70

- Pantawane, R., Maske, K. V., Kawade, N. S. (2017). Effects of Noise Pollution on Human Health. International Advanced Research Journal in Science, Engineering and Technology, 4 (3), 33–35.

- Burden of disease from environmental noise (2011). WHO, 128.

- Nehrii, S., Nehrii, T., Zolotarova, O., Glyva, V., Surzhenko, A., Tykhenko, O., Burdeina, N. (2022). Determining Priority of Risk Factors in Technological Zones of Longwalls. Journal of Mining and Environment, 13 (3), 751–765. https://doi.org/10.22044/jme.2022.12142.2216

- Glyva, V., Kasatkina, N., Levchenko, L., Tykhenko, O., Nazarenko, V., Burdeina, N. et al. (2022). Determining the dynamics of electromagnetic fields, air ionization, low-frequency sound and their normalization in premises for computer equipment. Eastern-European Journal of Enterprise Technologies, 3 (10 (117)), 47–55. https://doi.org/10.15587/1729-4061.2022.258939

- Glyva, V., Lyashok, J., Matvieieva, I., Frolov, V., Levchenko, L., Tykhenko, O. et al. (2018). Development and investigation of protective properties of the electromagnetic and soundproofing screen. Eastern-European Journal of Enterprise Technologies, 6 (5 (96)), 54–61. https://doi.org/10.15587/1729-4061.2018.150778

- Hearing protection. OSHwiki. Available at: https://oshwiki.osha.europa.eu/en/themes/hearing-protection

- Belšak, A., Prezelj, J. (2009). Visualisation and analysis of noise sources of a gear unit. Engineering Failure Analysis, 16 (5), 1570–1578. https://doi.org/10.1016/j.engfailanal.2008.10.011

- Occupational Noise Exposure. Standards. OSHA. Available at: https://www.osha.gov/noise/standards

- Criteria for a recommended standard. Occupational Noise Exposure. NIOSH. Available at: https://www.nonoise.org/hearing/criteria/criteria.htm

- Petrenko, I., Rieznik, D., Shevchenko, V., Volkov, O., Bilousova, K., Toś, P. (2024). Determining the impact of noise exposure of mining enterprises’ workers. E3S Web of Conferences, 526, 01008. https://doi.org/10.1051/e3sconf/202452601008

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Dmytro Rieznik, Serhii Sukach, Olga Chencheva, Yevhenii Lashko, Tatyana Kozlovskaya, Oleksandr Volkov, Ivan Petrenko, Oleh Mukha, Vitaly Hryniuk, Serhii Sapa

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.