Establishing patterns in the structure formation of polymer nanocomposites based on polyamide 6 during their crystallization processes

DOI:

https://doi.org/10.15587/1729-4061.2024.306965Keywords:

polymer nanocomposites, carbon nanotubes, silicon dioxide, crystallization exotherms, structure formation mechanismsAbstract

This paper reports experimental and computational studies on patterns in the structure formation of polymer nanocomposites when different types of fillers are used. The study was conducted for nanocomposites based on polyamide 6 filled with carbon nanotubes or silicon dioxide nanoparticles. In the course of research, the mass fraction of the filler varied from 0.2 % to 4.0 %, and the cooling rate of the melt composite varied from 0.5 K/min up to 20 K/min.

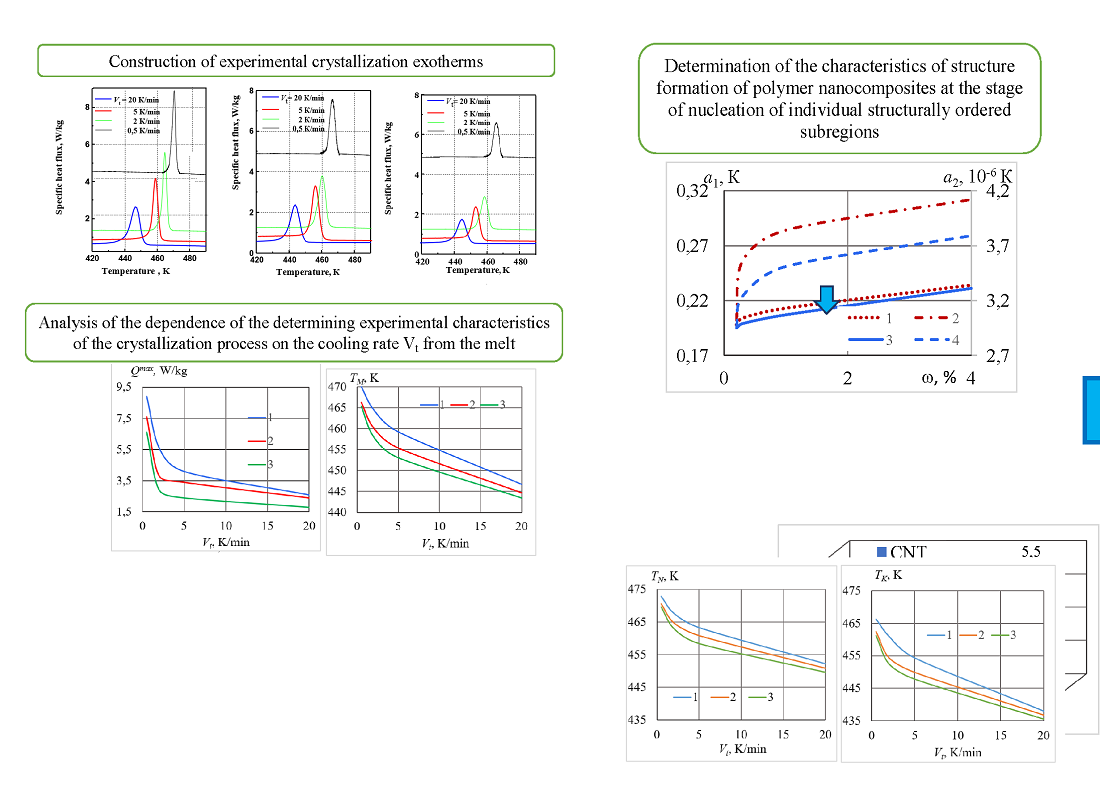

Data on experimental and theoretical studies into the mechanisms of structure formation of composites according to the method, which includes two stages, are given. According to the first stage, crystallization exotherms of nanocomposites were experimentally obtained when they are cooled from the melt at a given constant rate. The dependence of various characteristics of the crystallization process on the mass fraction of the filler and the cooling rate of the composite was established.

At the second stage, based on the analysis of the obtained crystallization exotherms, theoretical studies were performed to determine the mechanisms of structure formation of nanocomposites at different stages of crystallization. For the initial stage, according to the nucleation equation, the presence of two mechanisms of structure formation – planar and volumetric – has been shown.

Within the framework of the Kolmogorov-Avrami equation, the mechanisms of structure formation at the next stage of crystallization were established, which corresponds to the formation of ordered structures in the material within the volume of the polymer composite as a whole. The research was carried out assuming the existence of a mechanism of crystallization of the polymer matrix itself, which is realized on fluctuations in the density of the polymer, and a mechanism of crystallization, the centers of which are filler particles.

The use of the proposed nanocomposites is promising for the manufacture of parts of energy equipment, electronic equipment, elements of chemical, processing, defense industry installations, etc.

References

- Nikam, P. N., Deshpande, V. D. (2019). Isothermal crystallization kinetics of PET/alumina nanocomposites using distinct macrokinetic models. Journal of Thermal Analysis and Calorimetry, 138 (2), 1049–1067. https://doi.org/10.1007/s10973-019-08192-x

- Sethy, S., Samantaray, S. K., Satapathy, B. K. (2021). Dynamic crystallization behavior of PA-12/PP-MWCNT nanocomposites: non-isothermal kinetics approach. Journal of Polymer Engineering, 42 (2), 87–99. https://doi.org/10.1515/polyeng-2021-0195

- Fu, X., Dong, X., Yang, G., Bai, S. (2022). Non-isothermal crystallization kinetics of graphene/PA10T composites. Heliyon, 8 (8), e10206. https://doi.org/10.1016/j.heliyon.2022.e10206

- Wen, X., Su, Y., Li, S., Ju, W., Wang, D. (2021). Isothermal Crystallization Kinetics of Poly(ethylene oxide)/Poly(ethylene glycol)-g-silica Nanocomposites. Polymers, 13 (4), 648. https://doi.org/10.3390/polym13040648

- Yu, F., Xiao, L. (2021). Non-isothermal crystallization kinetics of poly(ether sulfone) functionalized graphene reinforced poly(ether ether ketone) composites. Polymer Testing, 97, 107150. https://doi.org/10.1016/j.polymertesting.2021.107150

- Mata-Padilla, J. M., Ávila-Orta, C. A., Almendárez-Camarillo, A., Martínez-Colunga, J. G., Hernández-Hernández, E., Cruz-Delgado, V. J. et al. (2020). Non-isothermal crystallization behavior of isotactic polypropylene/copper nanocomposites. Journal of Thermal Analysis and Calorimetry, 143 (4), 2919–2932. https://doi.org/10.1007/s10973-020-09512-2

- Dinzhos, R., Fialko, N., Prokopov, V., Sherenkovskiy, Y., Meranova, N., Koseva, N. et al. (2020). Identifying the influence of the polymer matrix type on the structure formation of microcomposites when they are filled with copper particles. Eastern-European Journal of Enterprise Technologies, 5 (6 (107)), 49–57. https://doi.org/10.15587/1729-4061.2020.214810

- Dolinskiy, A., Fialko, N., Dinzhos, R., Navrodskaya, R. (2015). Structure formation of polymer micro- and nanocomposites based on polycarbonate in the process of their crystallization. Thermophysics and Thermal Power Engineering, 37 (3), 5–15. https://doi.org/10.31472/ihe.3.2015.01

- Fialko, N., Dinzhos, R., Sherenkovskii, J., Meranova, N., Izvorska, D., Korzhyk, V. et al. (2021). Establishing patterns in the effect of temperature regime when manufacturing nanocomposites on their heat-conducting properties. Eastern-European Journal of Enterprise Technologies, 4 (5 (112)), 21–26. https://doi.org/10.15587/1729-4061.2021.236915

- Vunderlih, B. (1979). Fizika makromolekul. Vol. 2: Zarozhdenie, rost i otzhig kristallov. Moscow: Mir, 576.

- Privalko, E., Dinzhos, V., Rehteta, N., Vaschuk, A. (2013). Application of method of differential scanning calorimetry is for the study of mechanism of gelation of composition on the basis of carbonanotube. Visnyk Natsionalnoho aviatsiynoho universytetu, 2 (55), 214–218. Available at: http://nbuv.gov.ua/UJRN/Vnau_2013_2_34

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Nataliia Fialko, Nataliia Meranova, Julii Sherenkovskii, Raisa Navrodska, Vitalii Babak, Volodymyr Korzhyk, Maxim Lazarenko, Neli Koseva, Oksana Konoreva, Roman Dinzhos

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.