Identification of patterns of the stress-strain state of a standard plastic tank for liquid mineral fertilizers

DOI:

https://doi.org/10.15587/1729-4061.2024.308904Keywords:

plastic tanks, finite element method, strength calculation, wall thickness, tank motion modes, rotational molding, rotomoldingAbstract

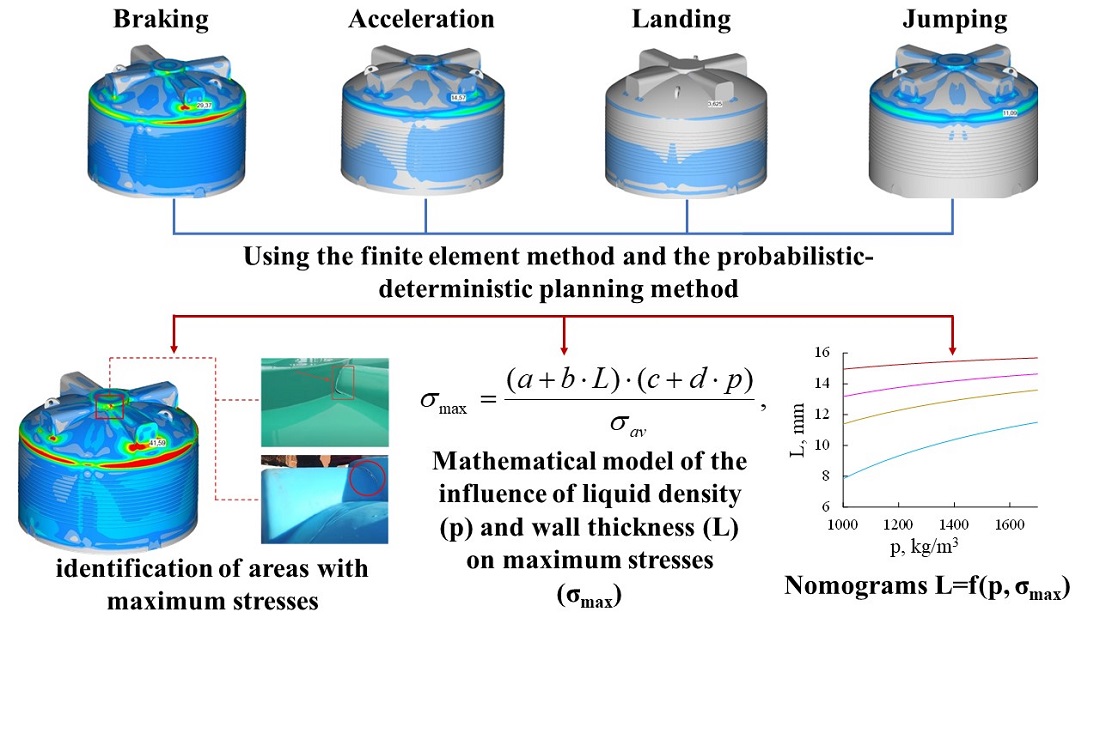

In this study, using the method of probabilistic deterministic planning (PDP), the optimum design parameters of a standard polyethylene tank used worldwide for transporting liquid mineral fertilizers (LMF) were determined.

By the finite element method, the effect of the density of liquid mineral fertilizer, tank wall thickness and four motion modes (braking, acceleration, jump and landing) on the strength of standard polyethylene tanks was studied. According to the results of the study, the five most informative areas in the tank design were identified, for which the values of maximum stresses (σmax) were obtained: filler neck, pockets, walls, tap-in points and wall transition to the tank roof. As the LMF density increases, σmax in the tank increases linearly. Increasing the tank wall thickness by 1.5 times reduces the maximum stresses by 30 to 50 %. It was found that motion mode has a significant effect on the stress-strain state of a standard tank. The “heaviest” mode for a standard tank is “braking”. The “acceleration” motion mode causes σmax of no more than 60 % of the “braking” mode values. The “lightest” mode is “landing”, in which σmax is no more than 28 % relative to “braking”. Based on the PDP method, equations were derived for calculating maximum stresses depending on LMF density, wall thickness and motion mode of the tank. Nomograms were built that make it possible to quickly determine the wall thickness of a standard tank without calculations, depending on external factors. The results of the study can be used in practice when designing safe and durable tanks for transporting liquid mineral fertilizers.

Supporting Agency

- During the research, the staff of the Department of

References

- Crawford, R. J., Throne, J. L. (2002). Rotational Molding Technology. William Andrew.

- Gupta, N., Ramkumar, P., Sangani, V. (2020). An approach toward augmenting materials, additives, processability and parameterization in rotational molding: a review. Materials and Manufacturing Processes, 35 (14), 1539–1556. https://doi.org/10.1080/10426914.2020.1779934

- Crawford, R. J. (1996). Recent advances in the manufacture of plastic products by rotomoulding. Journal of Materials Processing Technology, 56 (1-4), 263–271. https://doi.org/10.1016/0924-0136(95)01840-9

- Gnanaprakasam, P. D., Vanisree, A. J. (2022). Recurring detrimental impact of agrochemicals on the ecosystem, and a glimpse of organic farming as a possible rescue. Environmental Science and Pollution Research, 29 (50), 75103–75112. https://doi.org/10.1007/s11356-022-22750-1

- Hossain, M. E., Shahrukh, S., Hossain, S. A. (2022). Chemical Fertilizers and Pesticides: Impacts on Soil Degradation, Groundwater, and Human Health in Bangladesh. Water Science and Technology Library, 63–92. https://doi.org/10.1007/978-3-030-95542-7_4

- Khan, M. N., Mobin, M., Abbas, Z. K., Alamri, S. A. (2018). Fertilizers and Their Contaminants in Soils, Surface and Groundwater. Encyclopedia of the Anthropocene, 225–240. https://doi.org/10.1016/b978-0-12-809665-9.09888-8

- Timoshenko, S. (1956). Strength of Material. Part II. Advanced Theory and Problems. Princeton.

- Klabukova, L. S. (1980). The differential operator of problems of the theory of momentless elastic shells and their solution by the variational-difference method. USSR Computational Mathematics and Mathematical Physics, 20 (1), 225–244. https://doi.org/10.1016/0041-5553(80)90075-0

- Paimushin, V. N., Shalashilin, V. I. (2006). Geometrically non-linear equations in the theory of momentless shells with applications to problems on the non-classical forms of loss of stability of a cylinder. Journal of Applied Mathematics and Mechanics, 70 (1), 91–101. https://doi.org/10.1016/j.jappmathmech.2006.03.006

- Zha, S., Lan, H. (2021). Fracture behavior of pre-cracked polyethylene gas pipe under foundation settlement by extended finite element method. International Journal of Pressure Vessels and Piping, 189, 104270. https://doi.org/10.1016/j.ijpvp.2020.104270

- Khademi-Zahedi, R., Shishesaz, M. (2019). Application of a finite element method to stress distribution in buried patch repaired polyethylene gas pipes. Underground Space, 4 (1), 48–58. https://doi.org/10.1016/j.undsp.2018.05.001

- Khademi-Zahedi, R. (2019). Application of the finite element method for evaluating the stress distribution in buried damaged polyethylene gas pipes. Underground Space, 4 (1), 59–71. https://doi.org/10.1016/j.undsp.2018.05.002

- Kochanov, V., Píštěk, V., Kondratiev, A., Yuresko, T., Kučera, P. (2022). Influence of Geometric Parameters of Conical Acrylic Portholes on Their Stress–Strain Behaviour. Polymers, 14 (5), 1041. https://doi.org/10.3390/polym14051041

- Karamnov E. I. Application of the finite element method to solve the problem of stability of the tank wall. Applied research and development in priority areas of science and technology. Available at: http://econf.rae.ru/article/7560

- Vijay, K., Jayapalan, S. (2022). Creep analysis of Water tank made of Polypropylene (PP) and High-Density Polyethylene (HDPE) polymer material using ANSYS Simulation. Journal of Engineering Research. https://doi.org/10.36909/jer.17611

- Edlabadkar, O., Potdar, S., Jha, H. K., Jaiswal, N. G. (2022). Structural analysis of a rotomolded water tank. International Research Journal of En-gineering and Technology (IRJET). Available at: https://issuu.com/irjet/docs/irjet-v9i741#google_vignette

- Šuba, O., Bílek, O., Kubišová, M., Pata, V., Měřínská, D. (2022). Evaluation of the Flexural Rigidity of Underground Tanks Manufactured by Rotomolding. Applied Sciences, 12 (18), 9276. https://doi.org/10.3390/app12189276

- Pozhil, S. N., Menon, N. M., Waigaonkar, S. D., Chaudhari, V. (2020). An analytical model to predict the creep behaviour of linear low-density polyethylene (LLDPE) and polypropylene (PP) used in rotational moulding. Materials Today: Proceedings, 28, 888–892. https://doi.org/10.1016/j.matpr.2019.12.318

- Tyukanko, V., Demyanenko, A., Semenyuk, V., Dyuryagina, A., Alyoshin, D., Tarunin, R., Voropaeva, V. (2023). Development of an Ultrasonic Method for the Quality Control of Polyethylene Tanks Manufactured Using Rotational Molding Technology. Polymers, 15 (10), 2368. https://doi.org/10.3390/polym15102368

- Dyuryagina, A., Lutsenko, A., Demyanenko, A., Tyukanko, V., Ostrovnoy, K., Yanevich, A. (2022). Modeling the wetting of titanium dioxide and steel substrate in water-borne paint and varnish materials in the presence of surfactants. Eastern-European Journal of Enterprise Technologies, 1 (6 (115)), 31–42. https://doi.org/10.15587/1729-4061.2022.252757

- Tyukanko, V., Demyanenko, A., Dyuryagina, A., Ostrovnoy, K., Lezhneva, M. (2021). Optimization of the Composition of Silicone Enamel by the Taguchi Method Using Surfactants Obtained from Oil Refining Waste. Polymers, 13 (21), 3619. https://doi.org/10.3390/polym13213619

- Tyukanko, V., Demyanenko, A., Dyuryagina, A., Ostrovnoy, K., Aubakirova, G. (2022). Optimizing the Composition of Silicone Enamel to Ensure Maximum Aggregative Stability of Its Suspensions Using Surfactant Obtained from Oil Refining Waste. Polymers, 14 (18), 3819. https://doi.org/10.3390/polym14183819

- Dyuryagina, A. N., Lutsenko, A. A., Tyukanko, V. Yu. (2019). Study of the disperse effect of polymeric surface-active substances in acrylic dispersions used for painting oil well armature. Bull. Tomsk. Polytech. Univ. Geo Assets Eng., 330 (8), 37–44.

- E-ECE-TRANS-505. Soglasheniya o prinyatii edinoobraznyh tekhnicheskih predpisaniy dlya kolesnyh transportnyh sredstv, predmetov oborudovaniya i chastey, kotorye mogut byt' ustanovleny i/ili ispol'zovany na kolesnyh transportnyh sredstvah, i ob usloviyah vzaimnogo priznaniya ofitsial'nyh utverzhdeniy, vydavaemyh na osnove etih predpisaniy.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Vitaliy Tyukanko, Alexandr Demyanenko, Vladislav Semenyuk, Dmitriy Alyoshin, Stanislav Brilkov, Sergey Litvinov, Tatyana Shirina, Erlan Akhmetzhanov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.