Development of binders based on the СаО–Fe2O3 system

DOI:

https://doi.org/10.15587/1729-4061.2024.309128Keywords:

composite binder, specialized binder, alternative resources, 3d printing, aluminate cementsAbstract

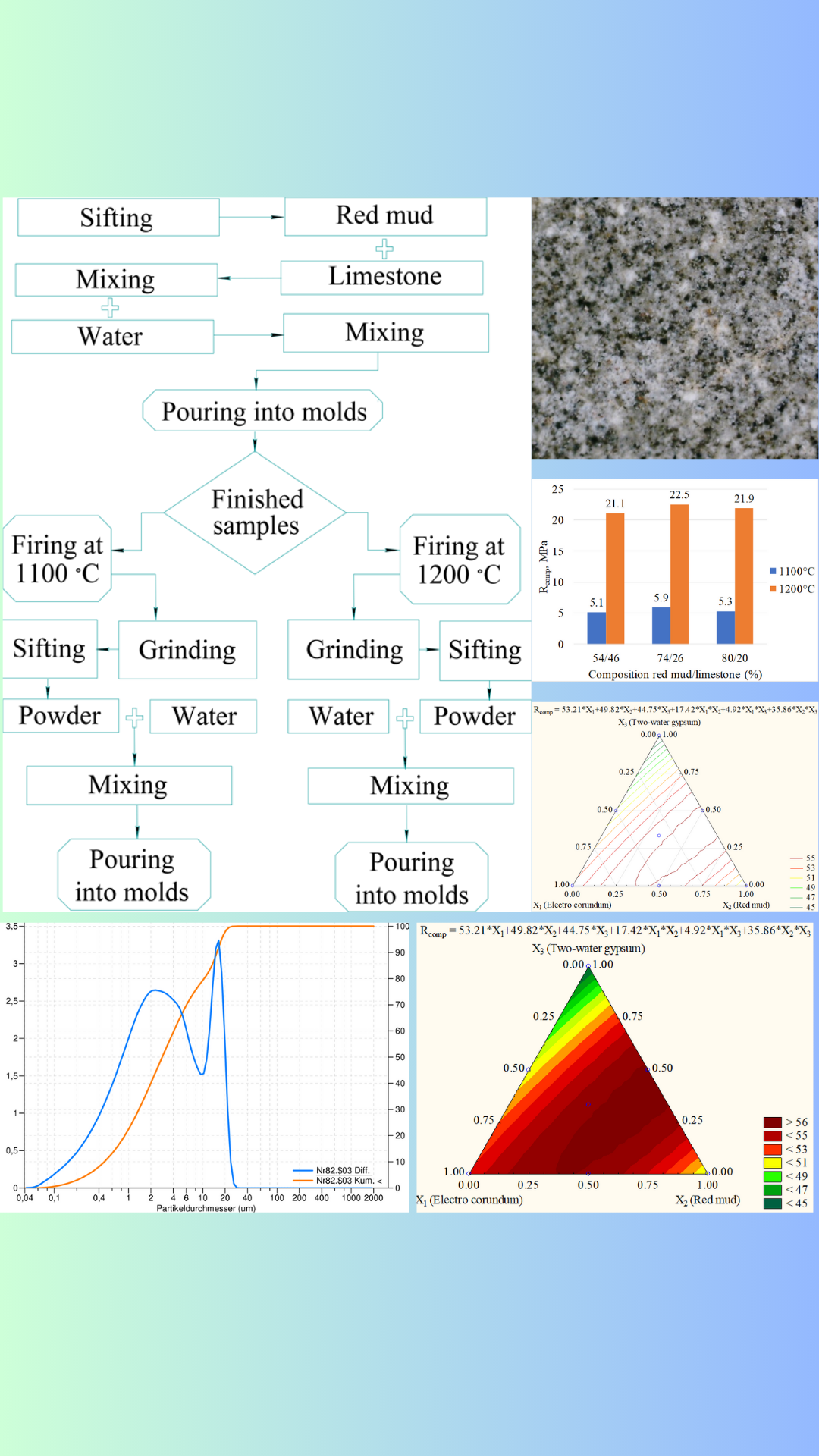

The object of research is the processes of structure formation and modeling of the properties of a specialized binder. The development of new binding materials based on production waste with high early strength indicators could make it possible to speed up construction period and is one of the urgent tasks at present. This study focused on the creation of binders based on the СаО–Fe2O3 system. The developed binder of the СаО–Fe2O3 system has the following composition: limestone – 26 %; red slime – 74 %, which has a dense fine-porous structure and high early strength indicators – 22.5 MPa with a density of 1960 kg/m3. There is also an increase in the average density of samples annealed at a temperature of 1200 ℃ for 60 minutes, ground and mixed with water, in comparison with samples fired at 1100 ℃ for 60 minutes, by 500 kg/m3, due to new formations. The prospect of using modified composite binders with special functional properties has been substantiated. The use of production waste based on the СаО-Fe2O3 system could make it possible to obtain materials with high physical and mechanical properties, which makes them promising for application in various areas of the construction industry. The development of such binders will help reduce the environmental impact of the construction industry, owing to the use of affordable and effective components. This approach will not only contribute to the improvement of the quality of building materials but also help reduce the ecological burden on the environment by using alternative resources and industrial waste. The developed binder could be used for the development of solutions for 3d printing, as well as repair of concrete coatings

References

- Krivenko, P. V., Kovalchuk, O., Zozulynets, V. (2023). Alternative binders – high volume bauxite red mud alkali activated cements and concretes. Recycled Concrete, 283–308. https://doi.org/10.1016/b978-0-323-85210-4.00001-1

- Krivenko, P., Rudenko, I., Konstantynovskyi, O., Vaičiukynienė, D. (2022). Mitigation of Corrosion Initiated by Cl− and SO42−-ions in Blast Furnace Cement Concrete Mixed with Sea Water. Materials, 15 (9), 3003. https://doi.org/10.3390/ma15093003

- Occhicone, A., Vukčević, M., Bosković, I., Mingione, S., Ferone, C. (2022). Alkali-Activated Red Mud and Construction and Demolition Waste-Based Components: Characterization and Environmental Assessment. Materials, 15 (4), 1617. https://doi.org/10.3390/ma15041617

- Occhicone, A., Vukčević, M., Bosković, I., Ferone, C. (2021). Red Mud-Blast Furnace Slag-Based Alkali-Activated Materials. Sustainability, 13 (20), 11298. https://doi.org/10.3390/su132011298

- Ministero Dello Sviluppo Economico. Available at: https://www.gazzettaufficiale.it/eli/id/2020/10/05/20A05394/sg

- Vavouraki, A. I. (2020). Utilization of Industrial Waste Slags to Enhance Ground Waste Concrete-Based Inorganic Polymers. Journal of Sustainable Metallurgy, 6 (3), 383–399. https://doi.org/10.1007/s40831-020-00281-8

- Khankhaje, E., Kim, T., Jang, H., Kim, C.-S., Kim, J., Rafieizonooz, M. (2024). A review of utilization of industrial waste materials as cement replacement in pervious concrete: An alternative approach to sustainable pervious concrete production. Heliyon, 10 (4), e26188. https://doi.org/10.1016/j.heliyon.2024.e26188

- Alias, C., Zerbini, I., Abbà, A., Benassi, L., Gelatti, U., Sorlini, S. et al. (2023). Ecotoxicity Evaluation of Industrial Waste and Construction Materials: Comparison Between Leachates from Granular Steel Slags and Steel Slags-Containing Concrete Through a Plant-Based Approach. Bulletin of Environmental Contamination and Toxicology, 111 (1). https://doi.org/10.1007/s00128-023-03764-y

- Qureshi, H. J., Ahmad, J., Majdi, A., Saleem, M. U., Al Fuhaid, A. F., Arifuzzaman, M. (2022). A Study on Sustainable Concrete with Partial Substitution of Cement with Red Mud: A Review. Materials, 15 (21), 7761. https://doi.org/10.3390/ma15217761

- Derevianko, V. M., Hryshko, H. M., Vatazhishin, O. V. (2023). Evaluation of the effectiveness of influence caused by ultra and nano-disperse additives for modification of sulfate phases and sulfoaluminate phases. Ukrainian Journal of Civil Engineering and Architecture, 4 (016), 71–76. https://doi.org/10.30838/j.bpsacea.2312.290823.71.972

- Azad, N. M., Samarakoon, S. M. S. M. K. (2021). Utilization of Industrial By-Products/Waste to Manufacture Geopolymer Cement/Concrete. Sustainability, 13 (2), 873. https://doi.org/10.3390/su13020873

- Akishev, K., Aryngazin, K., Tulegulov, A., Bayzharikova, M., Dulati Taraz, M. H., Nurtai, Zh. (2024). Evaluation of the efficiency of the technological process for the production of building products with fillers from metallurgical slag. Metalurgija, 63 (2), 267–270. Available at: https://hrcak.srce.hr/clanak/451094

- Derevianko, V. N., Moroz, L. V., Hryshko, H. M., Vatazhyshyn, O. V. (2023). Dyspersno-zalizobetony ta sumishi z mineralnymy ta orhanichnymy voloknamy. Shliakhy pidvyshchennia efektyvnosti budivnytstva v umovakh formuvannia rynkovykh vidnosyn, 52 (1), 181–195.

- Sanytsky, M., Kropyvnytska, T., Vakhula, O., Bobetsky, Y. (2023). Nanomodified Ultra High-Performance Fiber Reinforced Cementitious Composites with Enhanced Operational Characteristics. Proceedings of CEE 2023, 362–371. https://doi.org/10.1007/978-3-031-44955-0_36

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Victor Derevianko, Hanna Hryshko, Denis Smolin, Ivan Zhurba, Taras Dubov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.