Revealing patterns in reducing the fire-hazardous properties of insulation made from plant raw materials

DOI:

https://doi.org/10.15587/1729-4061.2024.309705Keywords:

protective means, insulation from hemp, hermal destruction of the surface, fire protection of hemp fibers, swelling of the coatingAbstract

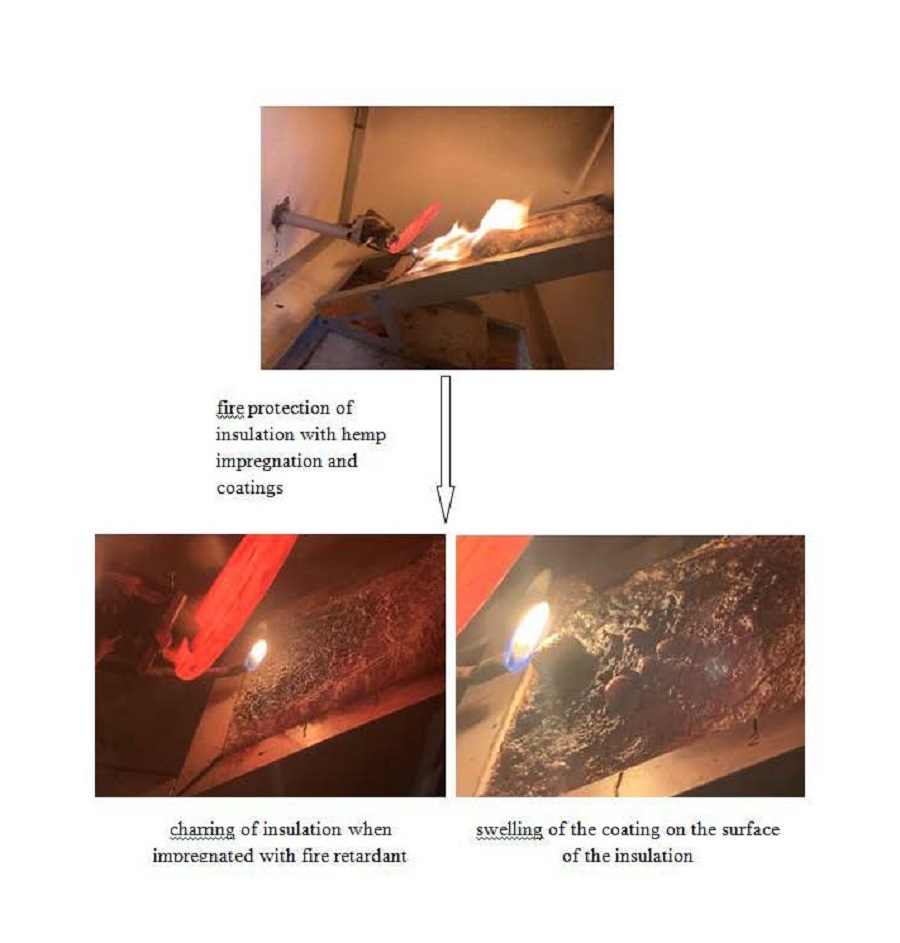

An issue related to the use of hemp bundle insulation for building structures is to ensure their fire resistance under the action of a low-calorie ignition source. Therefore, the object of research was the change in the properties of the insulation during fire protection with its compositions capable of forming a layer of pinocoke under the influence of high temperature. On the basis of experimental data, it was established that at fire protection of insulation with a fire retardant agent, hydrolytic stable ethers containing phosphorus and nitrogen atoms are formed on the surface of the fibers. According to the temperature values and the shape of peaks on the DTA curve, it was established that at fire protection, the height of the peaks decreases and the width increases, which characterize the flow of exothermic transformations and the destruction of hemp fibers. At the same time, it was established that the formed residue has 13.3 % for impregnation and 26.6 % for coating. It has been proven that in the process of thermal action on the fire-resistant coating, the heat insulation process of the insulation consists in the formation of soot-like products on the surface of the material. So, it was determined that the sample did not catch fire, it was charred in the place of the radiation panel, and the burning was not recorded. On the other hand, for a sample of insulation treated with a coating during thermal action, the formation of a heat-insulating layer of foam coke occurred, which inhibits the penetration of heat, the temperature of flue gases did not exceed 100 °C, and the flammability index was 0. The practical significance is that the results were taken into account when designing buildings and structures. So, there are reasons to assert the possibility of targeted regulation of fire protection processes of insulation by applying coatings that form a protective layer on the surface of the material

References

- Vidal, J., Ponce, D., Mija, A., Rymarczyk, M., Castell, P. (2023). Sustainable Composites from Nature to Construction: Hemp and Linseed Reinforced Biocomposites Based on Bio-Based Epoxy Resins. Materials, 16 (3), 1283. https://doi.org/10.3390/ma16031283

- Jiang, Y., Phelipot-Mardele, A., Collet, F., Lanos, C., Lemke, M., Ansell, M. et al. (2020). Moisture buffer, fire resistance and insulation potential of novel bio-clay plaster. Construction and Building Materials, 244, 118353. https://doi.org/10.1016/j.conbuildmat.2020.118353

- Sassoni, E., Manzi, S., Motori, A., Montecchi, M., Canti, M. (2014). Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energy and Buildings, 77, 219–226. https://doi.org/10.1016/j.enbuild.2014.03.033

- Kozlowski, R., Mieleniak, B., Muzyczek, M., Magnez, C., Mesnage, P. (2007). Flammability of lightweight, flexible insulating nonwoven made from natural fibrous raw materials. Proceedings of the 18th Annual Conference on Recent Advances in Flame Retardancy of Polymeric Materials, 330–340.

- Ben Hadj Tahar, D., Triki, Z., Guendouz, M., Tahraoui, H., Zamouche, M., Kebir, M. et al. (2024). Characterization and Thermal Evaluation of a Novel Bio-Based Natural Insulation Material from Posidonia oceanica Waste: A Sustainable Solution for Building Insulation in Algeria. ChemEngineering, 8 (1), 18. https://doi.org/10.3390/chemengineering8010018

- Fuentealba, C., Segovia, C., Vibert, C., Brosse, N. (2024). Eucalyptus Globulus Bark as Valuable Raw Material to the Development of Bio-Based Material. Proceedings of the 3rd International EUROMAGH Conference 2020, 76–87. https://doi.org/10.1007/978-981-97-2000-2_10

- Bozsaky, D., Ábrahám-Horváth, R. (2023). Laboratory tests on properties of innovative natural thermal insulation material. Pollack Periodica, 18 (2), 125–130. https://doi.org/10.1556/606.2022.00735

- Reza, M. M., Begum, H. A., Uddin, A. J. (2023). Potentiality of sustainable corn starch-based biocomposites reinforced with cotton filter waste of spinning mill. Heliyon, 9 (5), e15697. https://doi.org/10.1016/j.heliyon.2023.e15697

- Soto, M., Rojas, C., Cárdenas-Ramírez, J. P. (2022). Characterization of a Thermal Insulating Material Based on a Wheat Straw and Recycled Paper Cellulose to Be Applied in Buildings by Blowing Method. Sustainability, 15 (1), 58. https://doi.org/10.3390/su15010058

- Majumder, A., Stochino, F., Frattolillo, A., Fraternali, F., Martinelli, E. (2022). Jute fiber mortar composites for integrated retrofitting. Fib Symposium, 613–620. Available at: https://www.researchgate.net/profile/Arnas-Majumder/publication/369537567_Jute_fiber_mortar_composites_for_integrated_retrofitting/links/648ec927c41fb852dd0daf38/Jute-fiber-mortar-composites-for-integrated-retrofitting.pdf

- Majumder, A., Canale, L., Mastino, C. C., Pacitto, A., Frattolillo, A., Dell’Isola, M. (2021). Thermal Characterization of Recycled Materials for Building Insulation. Energies, 14 (12), 3564. https://doi.org/10.3390/en14123564

- Yu, S., Lee, J., Yeo, D., Lee, J., Bae, J., Sim, J. (2023). Analysis of Paint Properties According to Expandable Graphite and Fire Simulation Research on Firewall Penetration Part. Polymers, 16 (1), 98. https://doi.org/10.3390/polym16010098

- Takahashi, F. (2021). Fire blanket and intumescent coating materials for failure resistance. MRS Bulletin, 46 (5), 429–434. https://doi.org/10.1557/s43577-021-00102-7

- Vincent, T., Vincent, C., Dumazert, L., Otazaghine, B., Sonnier, R., Guibal, E. (2020). Fire behavior of innovative alginate foams. Carbohydrate Polymers, 250, 116910. https://doi.org/10.1016/j.carbpol.2020.116910

- Tsapko, Y., Tsapko, А. (2018). Establishment of fire protective effectiveness of reed treated with an impregnating solution and coatings. Eastern-European Journal of Enterprise Technologies, 4 (10 (94)), 62–68. https://doi.org/10.15587/1729-4061.2018.141030

- Pettersen, R. C. (1984). The Chemical Composition of Wood. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison. Available at: https://oeclass.aua.gr/eclass/modules/document/file.php/3383/ROGER%20C.%20PETTERSEN%201984%20The%20Chemical%20Composition%20of%20Wood%2070%20%CF%83%CE%B5%CE%BB.pdf

- Broido, A. (1969). A simple, sensitive graphical method of treating thermogravimetric analysis data. Journal of Polymer Science Part A-2: Polymer Physics, 7 (10), 1761–1773. https://doi.org/10.1002/pol.1969.160071012

- Tsapko, Y., Tsapko, А., Bondarenko, O. (2019). Effect of a flameretardant coating on the burning parameters of wood samples. Eastern-European Journal of Enterprise Technologies, 2 (10 (98)), 49–54. https://doi.org/10.15587/1729-4061.2019.163591

- Tsapko, Y., Tsapko, А., Bondarenko, O. (2020). Modeling the process of moisture diffusion by a flame-retardant coating for wood. Eastern-European Journal of Enterprise Technologies, 1 (10 (103)), 14–19. https://doi.org/10.15587/1729-4061.2020.192687

- Tsapko, Y., Tsapko, О., Bondarenko, O. (2020). Determination of the laws of thermal resistance of wood in application of fire-retardant fabric coatings. Eastern-European Journal of Enterprise Technologies, 2 (10 (104)), 13–18. https://doi.org/10.15587/1729-4061.2020.200467

- Tsapko, Y., Likhnyovskyi, R., Horbachova, O., Mazurchuk, S., Tsapko, А., Sokolenko, K. et al. (2022). Identifying parameters for wood protection against water absorption. Eastern-European Journal of Enterprise Technologies, 6 (10 (120)), 71–81. https://doi.org/10.15587/1729-4061.2022.268286

- Tsapko, Y., Tsapko, А., Likhnyovskyi, R., Sukhanevych, M., Zapolskiy, L., Illiuchenko, P., Bedratiuk, O. (2024). Establishing patterns in reducing fire-dangerous properties of sip panels fire-protected with reactive coating. Eastern-European Journal of Enterprise Technologies, 1 (10 (127)), 47–54. https://doi.org/10.15587/1729-4061.2024.298266

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Yuriy Tsapko, Аleksii Tsapko, Vitally Prisyazhnuk, Ruslan Klymas, Ruslan Likhnyovskyi, Oksana Slutskaya, Natalia Lialina, Kostiantyn Kaveryn

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.