Influence of heat treatment on the structure and mechanical properties of pseudo α-titanium alloy in a welded joint

DOI:

https://doi.org/10.15587/1729-4061.2024.310143Keywords:

electron beam welding, titanium alloys, heat treatment, mechanical properties, dispersion strengtheningAbstract

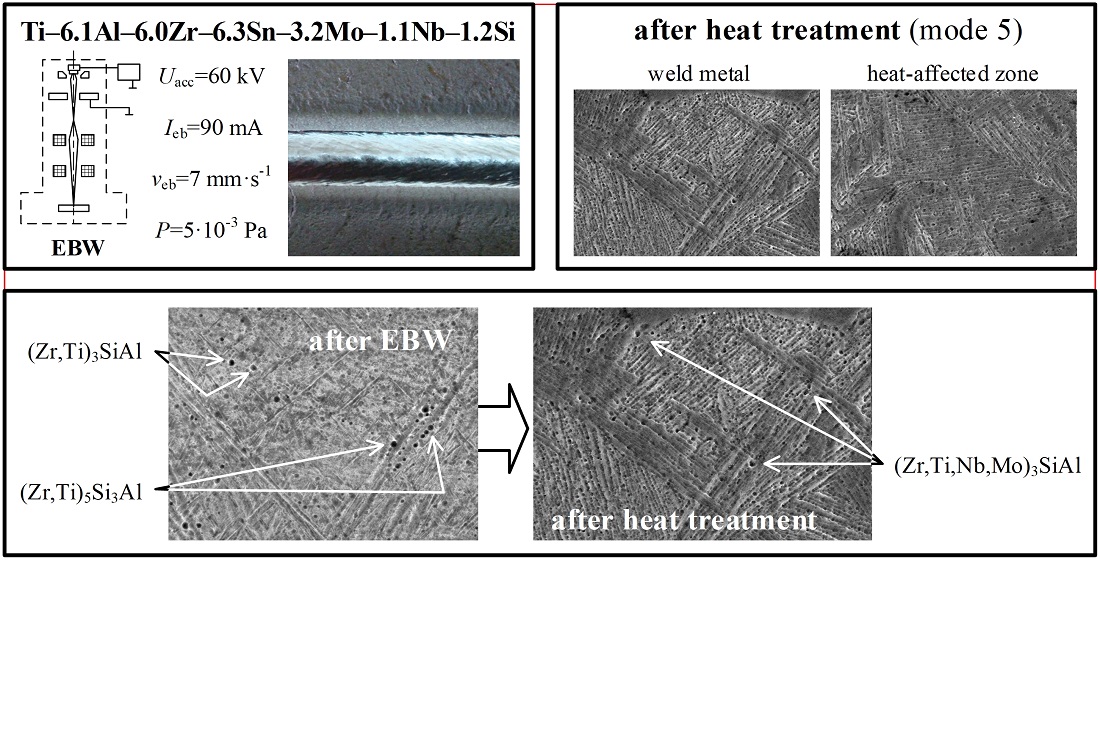

The object of this study was the weld material of a new Ti-6.1Al-6.0Zr-6.3Sn-3.2Mo-1.1Nb-1.2Si alloy, which was obtained by electron beam welding.

Electron beam welding (EBW) provides rapid melting and cooling with crystallization under significant temperature gradients. For the pseudo α-titanium alloy, this leads to the appearance of significant residual stresses in the joint and determines the specificity of the dispersion decay of the β-phase. Residual stresses are reduced by preliminary heating, removed by heat treatment. Such processing exerts a critical influence on the formation of the structure and phase composition of the weld and the zone of thermal influence of the electron beam; it can form macro defects, undesirable phases, and structural states.

The conditions of heat treatment have been determined to bring the welded joint from complex alloyed pseudo α-titanium alloy to the required level of mechanical characteristics. The structure, phase morphology, elemental composition, and mechanical characteristics of welded joints without additional heat treatment have been compared, with preliminary local heating of 400 °C, with additional post-weld local annealing at ТТ=750 °С, tT=4 minutes and sequential annealing in the furnace at ТТ=850 °C, tT=60 minutes. It has been established that a full cycle of heat treatment of a welded joint provides the highest characteristics of strength and plasticity, but local heat treatment also makes it possible to obtain a defect-free joint with satisfactory characteristics for less responsible products. It is shown how heat treatment of pseudo α-titanium alloy makes it possible to get rid of unwanted phase formations (Zr,Ti)5Si3Al and transform them into (Zr,Ti,Nb,Mo)3SiAl.

The results are promising for use in the production of aircraft engine parts

References

- Peters, M., Hemptenmacher, J., Kumpfert, J., Leyens, C. (2003). Structure and Properties of Titanium and Titanium Alloys. Titanium and Titanium Alloys, 1–36. https://doi.org/10.1002/3527602119.ch1

- Manda, P., Pathak, A., Mukhopadhyay, A., Chakkingal, U., Singh, A. K. (2017). Ti-5Al-5Mo-5V-3Cr and similar Mo equivalent alloys: First principles calculations and experimental investigations. Journal of Applied Research and Technology, 15 (1), 21–26. https://doi.org/10.1016/j.jart.2016.11.001

- Yang, Y. L., Wang, W. Q., Li, F. L., Li, W. Q., Zhang, Y. Q. (2009). The Effect of Aluminum Equivalent and Molybdenum Equivalent on the Mechanical Properties of High Strength and High Toughness Titanium Alloys. Materials Science Forum, 618-619, 169–172. https://doi.org/10.4028/www.scientific.net/msf.618-619.169

- Bulanova, M., Tretyachenko, L., Meleshevich, K., Saltykov, V., Vereshchaka, V., Galadzhyj, O. et al. (2003). Influence of tin on the structure and properties of as-cast Ti-rich Ti–Si alloys. Journal of Alloys and Compounds, 350 (1-2), 164–173. https://doi.org/10.1016/s0925-8388(02)00971-4

- Grigorenko, G. M., Zadorozhnyuk, O. M. (2012). Dispersionnoe uprochnenie – put' k povysheniyu prochnostnyh svoystv titanovyh splavov novogo pokoleniya (obzor). Sovremennaya elektrometallurgiya, 4, 42–49. Available at: http://nbuv.gov.ua/UJRN/sovele_2012_4_11

- Brodnikovskiy, D. N., Golovash, A. V., Tkachenko, S. V., Okun', I. Yu., Kuz'menko, N. N., Firstov, S. A. (2006). Vliyanie nedeformiruemyh chastits silitsida na harakter deformatsii splavov na osnove titana pri povyshennyh temperaturah. Metallofizika i noveyshie tekhnologii, 28, 165–174. Available at: https://www.researchgate.net/publication/290524943_Influence_of_rigid_particles_of_suicide_on_character_of_deformation_of_alloys_on_the_base_of_a_titanium_at_the_high_temperatures

- Sakamoto, T., Akiyama, H., Tange, S., Takebe, H. (2023). Age Hardening of Si-Bearing Near-α Titanium Alloy Ti–6Al–2.75Sn–4Zr–0.4Mo–0.45Si (Ti-1100) with Two Kinds of Initial Phases. Materials Transactions, 64 (9), 2246–2253. https://doi.org/10.2320/matertrans.mt-l2023003

- Grigorenko, G. M., Zadorozhnyuk, O. M. (2016). Struktura, mekhanicheskie svoystva i svarivaemost' psevdo-α- i (α+β)-Tі splavov, uprochnennyh silitsidami. Sovremennaya elektrometallurgiya, 2 (123), 51–56. Available at: https://patonpublishinghouse.com/sem/pdf/2016/pdfarticles/02/8.pdf

- Vrzhizhevskiy, E. L., Sabokar', V. K., Ahonin, S. V., Petrichenko, I. K. (2013). Vliyanie lokal'noy termicheskoy obrabotki pri ELS titanovyh splavov s silitsidnym uprochneniem na mekhanicheskie svoystva metalla shvov. Avtomaticheskaya svarka, 2, 21–24. Available at: http://nbuv.gov.ua/UJRN/as_2013_2_5

- Nesterenkov, V. M., Bondarev, A. A. (2014). Elektronno-luchevaya svarka krupnogabaritnyh tolstostennyh konstruktsiy iz splavov magniya. Avtomaticheskaya svarka, 2, 39–43. Available at: http://dspace.nbuv.gov.ua/handle/123456789/103265

- Loboda, P., Zvorykin, C., Zvorykin, V., Vrzhyzhevskyi, E., Taranova, T., Kostin, V. (2020). Production and Properties of Electron-Beam-Welded Joints on Ti-TiB Titanium Alloys. Metals, 10 (4), 522. https://doi.org/10.3390/met10040522

- Voron, M. M. (2012) Metodika rascheta poter' alyuminiya pri poluchenii splavov sistemy Ti-Al v usloviyah elektronno-luchevoy garnisazhnoy plavki. Protsessy lit'ya, 6, 22–25. Available at: http://nbuv.gov.ua/UJRN/PLN_2012_6_5

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Valerii Bilous, Eduard Vrzhyzhevskyi, Valery Kostin, Tatjana Taranova, Volodymyr Zvorykin, Constantine Zvorykin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.