Influence of fatty acid composition on contact angle and wear rate of Jatropha curcas and sunflower’s mixture by varying compositions mixture

DOI:

https://doi.org/10.15587/1729-4061.2024.310526Keywords:

wear rate, contact angle, molecular simulation, Jatropha curcas Linn. oil, sunflower oilAbstract

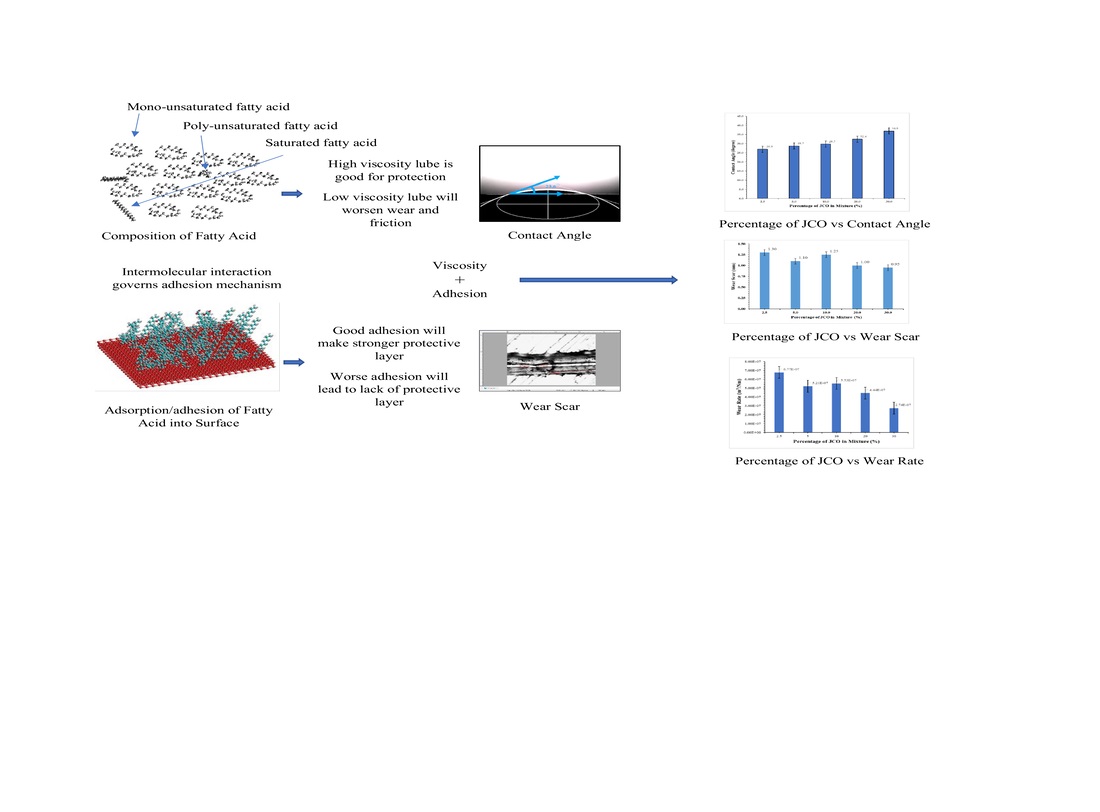

United Nation Sustainable Development Goals make sustainability become common goals which drives into investments of innovative product and technology focusing on sustainability. Cutting oils are generally made from mineral oil and the renewable replacement is sought after and one of them are Jatropha curcas and sunflower oil or blend of them. Viscosity and adsorption will influence the properties of cutting oil. The study concern on the relationship between percentage of JCO in the mixture to anti-wear properties and contact angle measured using goniometer contact angle and pin-on-disk tribometer by varying percentage of Jatropha curcas oil in mixtures for 2.5 %, 5 %, 10 %, 20 %, and 30 %. Also, molecular simulation is conducted through molecular dynamic in search of dipole moment, electrostatic potential, polarizability and bond energy. The approach is employed to connect molecular interaction and non-linearity trending of experiment. The experiment shows contact angle and wear scar width and also wear rate become higher when percentage of Jatropha curcas oil is higher. The lowest contact angle is 26.9 deg. and the highest is 36.9 deg. of 2.5 % and 30 % Jatropha oil. The highest wear rate is 6.77e-7 and the lowest is 2.74e-7 of 2.5 % and 30 % Jatropha oil. The simulation gives supporting basis in the finding of experiment in which the viscosity is more prominent in governing wear rate than adsorption. Increases of Jatropha curcas percentages have inversely proportional to dipole moment, polarizability, electrostatic potential and bonding which explain why the fatty acids become more adhere to the fatty acid than to surface. The finding is restricted only for idealized conditions both of molecular structure and surface.

References

- Luna, F. M. T., Cavalcante, J. B., Silva, F. O. N., Cavalcante, C. L. (2015). Studies on biodegradability of bio-based lubricants. Tribology International, 92, 301–306. https://doi.org/10.1016/j.triboint.2015.07.007

- Tang, L., Zhang, Y., Li, C., Zhou, Z., Nie, X., Chen, Y. et al. (2022). Biological Stability of Water-Based Cutting Fluids: Progress and Application. Chinese Journal of Mechanical Engineering, 35 (1). https://doi.org/10.1186/s10033-021-00667-z

- Afonso, I. S., Nobrega, G., Lima, R., Gomes, J. R., Ribeiro, J. E. (2023). Conventional and Recent Advances of Vegetable Oils as Metalworking Fluids (MWFs): A Review. Lubricants, 11 (4), 160. https://doi.org/10.3390/lubricants11040160

- Milano, J., Silitonga, A. S., Tiong, S. K., Ong, M. Y., Masudi, A., Hassan, M. H. et al. (2024). A Comprehensive exploration of jatropha curcas biodiesel production as a viable alternative feedstock in the fuel industry – Performance evaluation and feasibility analysis. Mechanical Engineering for Society and Industry, 4 (1), 17–37. https://doi.org/10.31603/mesi.10610

- Abdul Aziz, M. A. A., Hamzah, E., Selamat, M. (2022). Performances of plant based corrosion inhibitors in controlling corrosion of mild steel in sodium chloride environment. Materials Today: Proceedings, 51, 1344–1349. https://doi.org/10.1016/j.matpr.2021.11.385

- Zhang, X., Li, C., Zhou, Z., Liu, B., Zhang, Y., Yang, M. et al. (2023). Vegetable Oil-Based Nanolubricants in Machining: From Physicochemical Properties to Application. Chinese Journal of Mechanical Engineering, 36 (1). https://doi.org/10.1186/s10033-023-00895-5

- Narayana Sarma, R., Vinu, R. (2022). Current Status and Future Prospects of Biolubricants: Properties and Applications. Lubricants, 10 (4), 70. https://doi.org/10.3390/lubricants10040070

- Hermawan, A., Rahardja, I. B., Syam, M. Y., Sukismo, H., Fatah, N., Mardiono, M. (2019). Analysis of Viscosity of Lubricating Oil on Generator Machine Working Hours at KP. Macan Tutul 4203. Journal of Applied Sciences and Advanced Technology, 1 (3), 69–73. Available at: https://jurnal.umj.ac.id/index.php/JASAT/article/view/4312

- Rajasozhaperumal, G., Kannan, C. (2023). Comparative evaluation of chemically modified Jatropha oils as sustainable biolubricants in boundary lubrication regime. Tribology International, 186, 108594. https://doi.org/10.1016/j.triboint.2023.108594

- Biswas, M. A. S., Rahman, M. M., Ortega, J. A., Peña-Parás, L., Maldonado-Cortés, D., González, J. A. et al. (2022). Lubrication Performance of Sunflower Oil Reinforced with Halloysite Clay Nanotubes (HNT) as Lubricant Additives. Lubricants, 10 (7), 139. https://doi.org/10.3390/lubricants10070139

- Wang, Y., Li, C., Zhang, Y., Yang, M., Li, B., Jia, D. et al. (2016). Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. Journal of Cleaner Production, 127, 487–499. https://doi.org/10.1016/j.jclepro.2016.03.121

- Woma, T. Y., Ipilakyaa, T. D., Abdullahi, A. A., Okoro, U. G., Bello, A., Abutu, J. et al. (2023). Evaluation of Friction Co-efficient and Wear Performance of Jatropha Oil Using Standard Steel Ball on Aluminium Disc Tribometer. Journal of Materials and Environmental Science, 14 (10), 1266–1277. Available at: https://www.jmaterenvironsci.com/Document/vol14/vol14_N10/JMES-2023-14108-Woma.pdf

- Figueroa, M., García, E., Hernández, E. A. G., Vite-Torres, M. (2014). Friction and Wear of Jatropha curcas Oil Using a Four Balls Tester. Advanced Materials Research, 902, 76–81. https://doi.org/10.4028/www.scientific.net/amr.902.76

- Ma, Y., Wu, Y., Lee, J. G., He, L., Rother, G., Fameau, A.-L. et al. (2020). Adsorption of Fatty Acid Molecules on Amine-Functionalized Silica Nanoparticles: Surface Organization and Foam Stability. Langmuir, 36 (14), 3703–3712. https://doi.org/10.1021/acs.langmuir.0c00156

- Ma‘arif, Moch. S., Wardana, I. N. G., Darmadi, D. B., Novareza, O., Abidin, Z., Sulistyo, E., Darsono, C. H. (2024). The Influence of Eugenol in Lubrication Properties of Crude Jatropha Curcas Lin. International Journal of Integrated Engineering, 16 (2). https://doi.org/10.30880/ijie.2024.16.02.017

- Edem, D. O. (2002). Palm oil: Biochemical, physiological, nutritional, hematological and toxicological aspects: A review. Plant Foods for Human Nutrition, 57 (3/4), 319–341. https://doi.org/10.1023/a:1021828132707

- Designation: G 99-95a (Reapproved 2000)e1. Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM. Available at: https://cdn.standards.iteh.ai/samples/9915/022a33a120e74c24a23b628770221138/ASTM-G99-95a-2000-e1.pdf

- Farrokhnia, M. (2020). Density Functional Theory Studies on the Antioxidant Mechanism and Electronic Properties of Some Bioactive Marine Meroterpenoids: Sargahydroquionic Acid and Sargachromanol. ACS Omega, 5 (32), 20382–20390. https://doi.org/10.1021/acsomega.0c02354

- Cho, K. (2005). Polarizabilities. Encyclopedia of Condensed Matter Physics, 341–347. https://doi.org/10.1016/b0-12-369401-9/00603-3

- Bibi, S., Ur-rehman, S., Khalid, L., Bhatti, I. A., Bhatti, H. N., Iqbal, J. et al. (2022). Investigation of the adsorption properties of gemcitabine anticancer drug with metal-doped boron nitride fullerenes as a drug-delivery carrier: a DFT study. RSC Advances, 12 (5), 2873–2887. https://doi.org/10.1039/d1ra09319c

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Moch. Syamsul Ma’arif, I Nyoman Gede Wardana, Djarot B. Darmadi, Oyong Novareza, Nanu Admantara, Iis Siti Aisyah

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.