Development of oat malt production technology using plasma-chemically activated aqueous solutions

DOI:

https://doi.org/10.15587/1729-4061.2024.311477Keywords:

malting, oat malt, gluten-free product, plasma-chemical activation, hydrogen peroxideAbstract

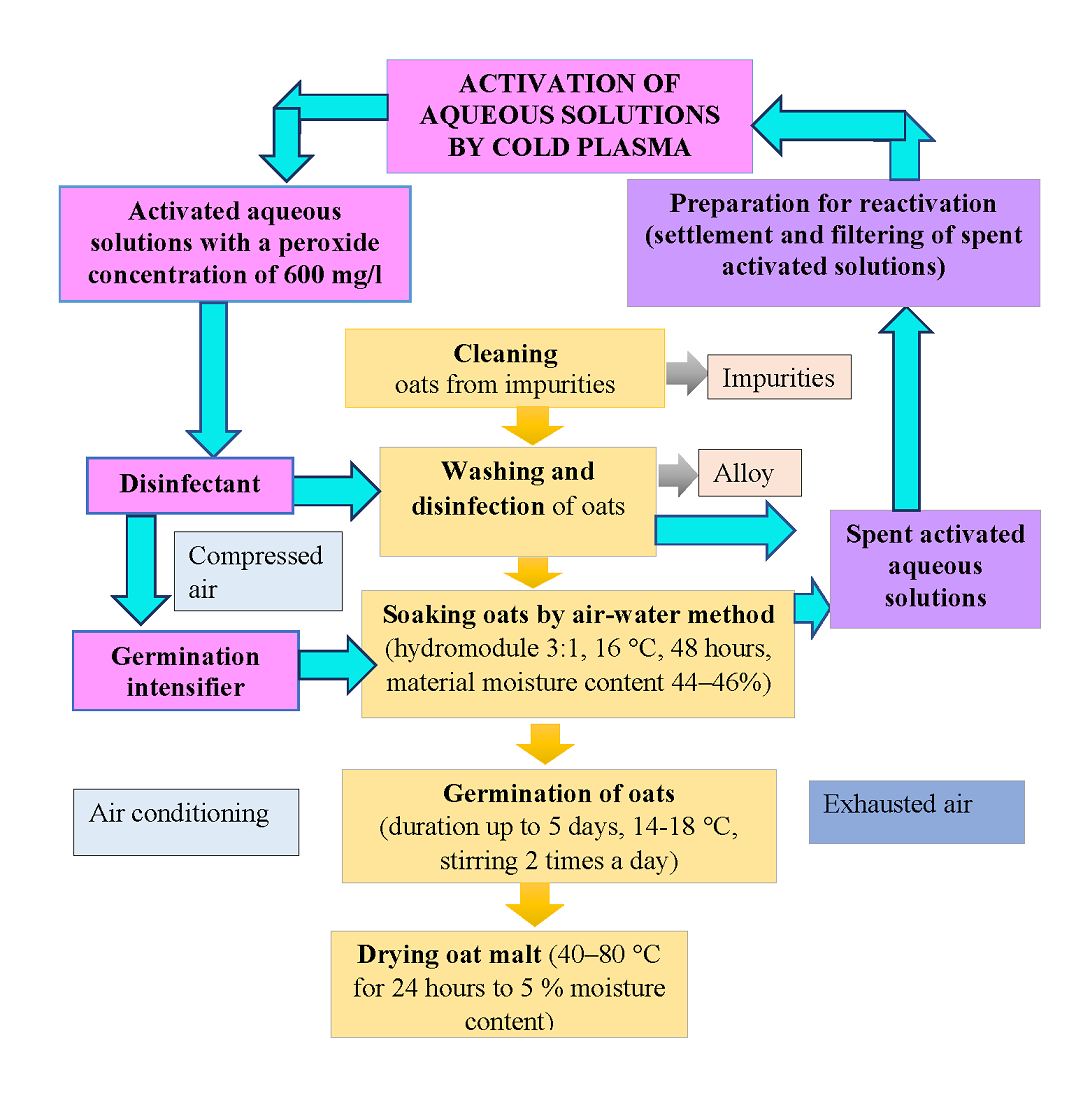

The object of the study was oat malt production. The result of the presented study is the development of a technology for gluten-free oat malt production using cold plasma-treated technological solutions. The material for the study was oat grain. The main technological task is to obtain high-quality oat malt, which, in turn, will be suitable for producing gluten-free beverages and highly nutritious foods. The expediency of using cold plasma-treated aqueous solutions as an activator of the oat malting process and an effective disinfectant of the technological process and the finished product (oat malt) was experimentally proved. It was confirmed that using cold plasma-treated aqueous solutions can accelerate the oat germination process: the germination energy increased by 6–14 %; germination capacity by 2–10 %. The moisture content of oats when moistened increases by 6–37 %. Analysis of the amylolytic enzymatic activity showed a dynamic increase of 17.6 %. The result was the breakdown of carbohydrates. Thus, the amount of starch decreased by 2.4 %, fiber did not undergo significant changes, and the content of simple sugars increased by 2.3 %. The proteolytic activity of oat malt increased by 18.1 %. An increase in the amount of amino acids in the experimental samples was noted. The total amount of amino acids is 793 mg/100 g of product higher than in the control (i.e. by 3 %). There was also an increase in the content of vitamins B (B1, B2), as well as vitamin C, the content of which increased by 5.6 %. Disinfecting properties of cold plasma-treated aqueous solutions in relation to oat malt were noted.

The innovative technology of oat malt production can be implemented in the industrial production of gluten-free malts for the brewing industry and for producing gluten-free foods.

References

- Kovalova, O., Vasylieva, N., Haliasnyi, I., Gavrish, T., Dikhtyar, A., Andrieieva, S. et al. (2024). Development of technology for the production of all-purpose buckwheat malt using plasmochemically activated aqueous solutions. Eastern-European Journal of Enterprise Technologies, 1 (11 (127)), 38–51. https://doi.org/10.15587/1729-4061.2024.298797

- Gangopadhyay, N., Hossain, M., Rai, D., Brunton, N. (2015). A Review of Extraction and Analysis of Bioactives in Oat and Barley and Scope for Use of Novel Food Processing Technologies. Molecules, 20 (6), 10884–10909. https://doi.org/10.3390/molecules200610884

- Bouchard, J., Valookaran, A. F., Aloud, B. M., Raj, P., Malunga, L. N., Thandapilly, S. J., Netticadan, T. (2022). Impact of oats in the prevention/management of hypertension. Food Chemistry, 381, 132198. https://doi.org/10.1016/j.foodchem.2022.132198

- Ispiryan, L., Kuktaite, R., Zannini, E., Arendt, E. K. (2021). Fundamental study on changes in the FODMAP profile of cereals, pseudo-cereals, and pulses during the malting process. Food Chemistry, 343, 128549. https://doi.org/10.1016/j.foodchem.2020.128549

- Gumienna, M., Górna, B. (2020). Gluten hypersensitivities and their impact on the production of gluten-free beer. European Food Research and Technology, 246 (11), 2147–2160. https://doi.org/10.1007/s00217-020-03579-9

- Orhotohwo, O. L., Czipa, N., Kovács, B., Alexa, L. (2021). Impacts of the use of gluten-free cereals and spices on the quality parameters of beer. Journal of Microbiology, Biotechnology and Food Sciences, 11 (1), e3838. https://doi.org/10.15414/jmbfs.3838

- Zdaniewicz, M., Pater, A., Knapik, A., Duliński, R. (2021). The effect of different oat (Avena sativa L) malt contents in a top-fermented beer recipe on the brewing process performance and product quality. Journal of Cereal Science, 101, 103301. https://doi.org/10.1016/j.jcs.2021.103301

- Yang, D., Gao, X. (2020). Progress of the use of alternatives to malt in the production of gluten-free beer. Critical Reviews in Food Science and Nutrition, 62 (10), 2820–2835. https://doi.org/10.1080/10408398.2020.1859458

- Bridges, A. R., Wrigley, C. W. (2016). Standardized Test Methods for Grains and Grain-Based Products. Encyclopedia of Food Grains, 300–307. https://doi.org/10.1016/b978-0-12-394437-5.00114-5

- Blšáková, L., Gregor, T., Mešťánek, M., Hřivna, L., Kumbár, V. (2021). The Use of Unconventional Malts in Beer Production and Their Effect on the Wort Viscosity. Foods, 11 (1), 31. https://doi.org/10.3390/foods11010031

- Gasiński, A., Kawa-Rygielska, J., Błażewicz, J., Leszczyńska, D. (2022). Malting procedure and its impact on the composition of volatiles and antioxidative potential of naked and covered oat varieties. Journal of Cereal Science, 107, 103537. https://doi.org/10.1016/j.jcs.2022.103537

- Chusova, A. E., Zelenkova, A. V., Novikova, I. V., Zueva, N. V., Romanyuk, T. I., Kulneva, N. G. (2022). Bio-processing of oats to make malt. IOP Conference Series: Earth and Environmental Science, 1052 (1), 012005. https://doi.org/10.1088/1755-1315/1052/1/012005

- Miller, Y. Yu., Kiseleva, T., Pomozova, V. (2024). Using non-traditional raw materials in the production of grain beverages. BIO Web of Conferences, 103, 00092. https://doi.org/10.1051/bioconf/202410300092

- Herrera-Ponce, A. L., Salmeron-Ochoa, I., Rodriguez-Figueroa, J. C., Santellano-Estrada, E., Garcia-Galicia, I. A., Alarcon-Rojo, A. D. (2021). High-intensity ultrasound as pre-treatment in the development of fermented whey and oat beverages: effect on the fermentation, antioxidant activity and consumer acceptance. Journal of Food Science and Technology, 59 (2), 796–804. https://doi.org/10.1007/s13197-021-05074-9

- Gematdinova, V. M., Kanarskiy, A. V., Kanarskaya, Z. A., Kruchina-Bogdanov, I. V. (2019). Production of β-glucan concentrate by oat germination. Chemistry of Plant Raw Material, 2, 231–237. https://doi.org/10.14258/jcprm.2019024251

- Salamon, A., Kowalska, H., Ignaczak, A., Marzec, A., Kowalska, J., Szafrańska, A. (2023). Characteristics of Oat and Buckwheat Malt Grains for Use in the Production of Fermented Foods. Foods, 12 (20), 3747. https://doi.org/10.3390/foods12203747

- Salamon, A., Kowalska, H., Stępniewska, S., Szafrańska, A. (2024). Evaluation of the Possibilities of Using Oat Malt in Wheat Breadmaking. Applied Sciences, 14 (10), 4101. https://doi.org/10.3390/app14104101

- Vasylieva, N., Velychko, O. (2017). Development of the controlling system in the management of dairy clusters. Eastern-European Journal of Enterprise Technologies, 4 (3 (88)), 20–26. https://doi.org/10.15587/1729-4061.2017.108591

- Anthero, A. G. S., Lima, J. M., Cleto, P. B., Jorge, L. M. M., Jorge, R. M. M. (2019). Modeling of maceration step of the oat (Avena sativa) malting process. Journal of Food Process Engineering, 42 (7). https://doi.org/10.1111/jfpe.13266

- Fang, Y., Franke, C., Manthei, A., McMullen, L., Temelli, F., Gänzle, M. G. (2021). Effects of high-pressure carbon dioxide on microbial quality and germination of cereal grains and beans. The Journal of Supercritical Fluids, 175, 105272. https://doi.org/10.1016/j.supflu.2021.105272

- Kovaliova, O., Vasylieva, N., Stankevych, S., Zabrodina, I., Mandych, O., Hontar, T. et al. (2023). Development of a technology for the production of germinated flaxseed using plasma-chemically activated aqueous solutions. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 6–19. https://doi.org/10.15587/1729-4061.2023.284810

- Kovaliova, O., Pivovarov, O., Kalyna, V., Tchoursinov, Y., Kunitsia, E., Chernukha, A. et al. (2020). Implementation of the plasmochemical activation of technological solutions in the process of ecologization of malt production. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 26–35. https://doi.org/10.15587/1729-4061.2020.215160

- Pivovarov, O., Kovaliova, O., Koshulko, V. (2020). Effect of plasmochemically activated aqueous solution on process of food sprouts production. Ukrainian Food Journal, 9 (3), 576–587. https://doi.org/10.24263/2304-974x-2020-9-3-7

- Kovalova, O., Vasylieva, N., Haliasnyi, I., Gavrish, T., Dikhtyar, A., Andrieieva, S. et al. (2023). Development of buckwheat groats production technology using plasma-chemically activated aqueous solutions. Eastern-European Journal of Enterprise Technologies, 6 (11 (126)), 59–72. https://doi.org/10.15587/1729-4061.2023.290584

- Kovalova, O., Vasylieva, N., Stankevych, S., Zabrodina, I., Haliasnyi, I., Gontar, T. et al. (2023). Determining the effect of plasmochemically activated aqueous solutions on the bioactivation process of sea buckthorn seeds. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 99–111. https://doi.org/10.15587/1729-4061.2023.275548

- Kovalova, O., Vasylieva, N., Zhulinska, O., Balandina, I., Zhukova, L., Bezpal’ko, V. et al. (2024). Development of lentil malt production technology using plasma-chemically activated aqueous solutions. Technology and Equipment of Food Production, 4 (11 (130)), 76–86. https://doi.org/10.15587/1729-4061.2024.308298

- Cetinkaya-Rundel, R., Hardin, J. (2021). Introduction to Modern Statistics. OpenIntro, 549.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Olena Kovalova, Natalia Vasylieva, Aliona Dikhtyar, Svitlana Andrieieva, Svitlana Omelchenko, Oleh Kotliar, Andrii Kariyk, Serhii Rudakov, Serhii Harbuz, Liudmyla Onyshchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.