Improving the technology of gluten-free bread with quinoa flour

DOI:

https://doi.org/10.15587/1729-4061.2024.313159Keywords:

flour mixture, saponins, quinoa, ultrasound treatment, liquid starter, spontaneous fermentationAbstract

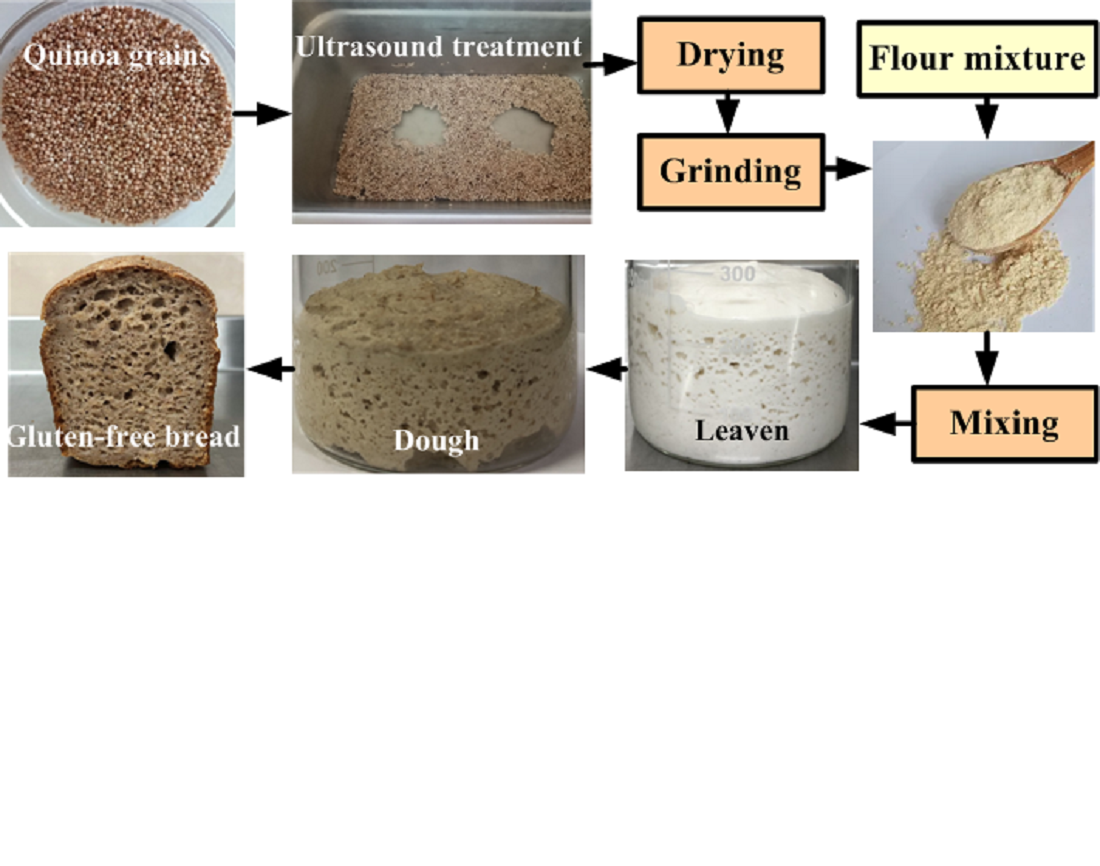

The object of this study is the technology of bread baking based on liquid sourdough and gluten-free flour mixture. The problem with this technology is that gluten-free raw materials do not contain gluten proteins, which ensure the elasticity and firmness of the dough and increase the porosity of the bread. To improve the structural and mechanical properties of the dough, new types of flour were introduced into the recipe compared to the analog recipe: quinoa, buckwheat, and oat. The positive effect of quinoa on dough quality has been known for a long time but the limitation in its use is the bitter taste caused by the content of saponins. A method of removing saponins using ultrasound (40 kHz, τ=20 min) has been proposed, which made it possible to remove 60 % of saponins and completely remove the bitterness of grains. At the same time, the content of proteins remained unchanged while the content of phenols decreased by only 0.1 mg GAE/g. The addition of 18 % (to the mass of the flour mixture) of quinoa flour and the reduction of the starch content in the recipe had a positive effect on the organoleptic parameters of the bread quality. The acidity of dough (4.4–5.2 °Н) and bread (0.6 °Н) decreased compared to the control sample, but it was sufficient for a normal fermentation process. Bread with quinoa flour had increased moisture (more than 66 %), which can negatively affect its stability during storage. An increase in the proportion of quinoa flour in the recipe by 5 % contributed to an increase in the porosity of the crumb by 2.1 %. The proposed technology for making gluten-free bread with Quartet quinoa flour based on liquid sourdough can be industrially implemented as it makes it possible to obtain a product with desirable consumer properties. The total duration of dough ripening was reduced by 1–1.5 hours, compared to the steam method, which increases the economic efficiency of the proposed technology.

References

- Kraft, M., Dölle-Bierke, S., Renaudin, J.-M., Ruëff, F., Scherer Hofmeier, K., Treudler, R. et al. (2021). Wheat Anaphylaxis in Adults Differs from Reactions to Other Types of Food. The Journal of Allergy and Clinical Immunology: In Practice, 9 (7), 2844–2852.e5. https://doi.org/10.1016/j.jaip.2021.03.037

- Utarova, N., Kakimov, M., Gajdzik, B., Wolniak, R., Nurtayeva, A., Yeraliyeva, S., Bembenek, M. (2024). Development of Gluten-Free Bread Production Technology with Enhanced Nutritional Value in the Context of Kazakhstan. Foods, 13 (2), 271. https://doi.org/10.3390/foods13020271

- Mystkowska, I., Plażuk, E., Szepeluk, A., Dmitrowicz, A. (2024). Gluten-containing flours and gluten-free flours as a source of calcium, magnesium, iron and zinc. Scientific Reports, 14 (1). https://doi.org/10.1038/s41598-024-65530-2

- Kowalska, S., Szłyk, E., Jastrzębska, A. (2021). Simple extraction procedure for free amino acids determination in selected gluten-free flour samples. European Food Research and Technology, 248 (2), 507–517. https://doi.org/10.1007/s00217-021-03896-7

- Bravi, E., Sileoni, V., Marconi, O. (2024). Quinoa (Chenopodium Quinoa Willd.) as Functional Ingredient for the Formulation of Gluten-Free Shortbreads. Foods, 13 (3), 377. https://doi.org/10.3390/foods13030377

- Ramos-Pacheco, B. S., Choque-Quispe, D., Ligarda-Samanez, C. A., Solano-Reynoso, A. M., Palomino-Rincón, H., Choque-Quispe, Y. et al. (2024). Effect of Germination on the Physicochemical Properties, Functional Groups, Content of Bioactive Compounds, and Antioxidant Capacity of Different Varieties of Quinoa (Chenopodium quinoa Willd.) Grown in the High Andean Zone of Peru. Foods, 13 (3), 417. https://doi.org/10.3390/foods13030417

- Agarwal, A., Rizwana, Tripathi, A. D., Kumar, T., Sharma, K. P., Patel, S. K. S. (2023). Nutritional and Functional New Perspectives and Potential Health Benefits of Quinoa and Chia Seeds. Antioxidants, 12 (7), 1413. https://doi.org/10.3390/antiox12071413

- da Silva, R. P., Reyes, F. J. V., Daniel, J. S. P., da Silva Pestana, J. E., de Almeida Pires, S., Ferraz, H. G. (2024). Using Chia Powder as a Binder to Obtain Chewable Tablets Containing Quinoa for Dietary Fiber Supplementation. Powders, 3 (2), 202–216. https://doi.org/10.3390/powders3020013

- Casalvara, R. F. A., Ferreira, B. M. R., Gonçalves, J. E., Yamaguchi, N. U., Bracht, A., Bracht, L. et al. (2024). Biotechnological, Nutritional, and Therapeutic Applications of Quinoa (Chenopodium quinoa Willd.) and Its By-Products: A Review of the Past Five-Year Findings. Nutrients, 16 (6), 840. https://doi.org/10.3390/nu16060840

- Bielecka, J., Markiewicz-Żukowska, R., Puścion-Jakubik, A., Grabia, M., Nowakowski, P., Soroczyńska, J., Socha, K. (2022). Gluten-Free Cereals and Pseudocereals as a Potential Source of Exposure to Toxic Elements among Polish Residents. Nutrients, 14 (11), 2342. https://doi.org/10.3390/nu14112342

- Rafik, S., Rahmani, M., Rodriguez, J. P., Andam, S., Ezzariai, A., El Gharous, M. et al. (2021). How Does Mechanical Pearling Affect Quinoa Nutrients and Saponin Contents? Plants, 10 (6), 1133. https://doi.org/10.3390/plants10061133

- El Hazzam, K., Mhada, M., Metougui, M. L., El Kacimi, K., Sobeh, M., Taourirte, M., Yasri, A. (2022). Box–Behnken Design: Wet Process Optimization for Saponins Removal From Chenopodium quinoa Seeds and the Study of Its Effect on Nutritional Properties. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.906592

- Xue, P., Zhao, L., Wang, Y., Hou, Z., Zhang, F., Yang, X. (2019). Reducing the damage of quinoa saponins on human gastric mucosal cells by a heating process. Food Science & Nutrition, 8 (1), 500–510. https://doi.org/10.1002/fsn3.1332

- Montañez Artica, W. M., Ramos Gómez, J. F., Sinche Charca, S. A., Hurtado-Soria, B. Z., Tamara Tamariz, S. J., Villanueva López, E. (2024). Design and construction of equipment for the elimination of saponin in Quinoa (Chenopodium quinoa Willd): Performance tests with Amarillo Marangani variety. TAYACAJA, 7 (1), 31–39. https://doi.org/10.46908/tayacaja.v7i1.221

- Espinoza, C. R., Ruiz, C. A. J., Ramos, O. P. F., Solano, M. A. Q., Quiñonez, G. H., Mallma, N. E. S. (2021). Optimization of the ultrasoud-assisted extraction of saponins from quinoa (Chenopodium quinoa Wild) using response surface methodology. Acta Scientiarum Polonorum Technologia Alimentaria, 20 (1), 17–23. https://doi.org/10.17306/j.afs.0859

- Ragonese, V. E., Moscoso Ospina, Y. A., Cabezas, D. M., Kakisu, E. J. (2024). Effect of ultrasound treatment on the composition and emulsifying properties of quinoa okara. International Journal of Food Science & Technology, 59 (3), 1481–1489. https://doi.org/10.1111/ijfs.16896

- Ammar, I., Sebii, H., Aloui, T., Attia, H., Hadrich, B., Felfoul, I. (2022). Optimization of a novel, gluten-free bread’s formulation based on chickpea, carob and rice flours using response surface design. Heliyon, 8 (12), e12164. https://doi.org/10.1016/j.heliyon.2022.e12164

- Samilyk, M., Demidova, E., Nazarenko, Y., Tymoshenko, A., Ryzhkova, T., Severin, R., Hnoievyі, I., Yatsenko, I. (2023). Formation of the quality and shelf life of bread through the addition of rowanberry powder. Eastern-European Journal of Enterprise Technologies, 3 (11 (123)), 42–49. https://doi.org/10.15587/1729-4061.2023.278799

- Tumpaung, R., Thobunluep, P., Kongsil, P., Onwimol, D., Lertmongko, S., Sarobol, E. et al. (2021). Comparison of Grain Processing Techniques on Saponin Content and Nutritional Value of Quinoa (Chenopodium quinoa Cv. Yellow Pang-da) Grain. Pakistan Journal of Biological Sciences, 24 (7), 821–829. https://doi.org/10.3923/pjbs.2021.821.829

- Li, L., Lietz, G., Seal, C. J. (2021). Phenolic, apparent antioxidant and nutritional composition of quinoa (Chenopodiumquinoa Willd.) seeds. International Journal of Food Science & Technology, 56 (7), 3245–3254. https://doi.org/10.1111/ijfs.14962

- Aguiar, E. V., Santos, F. G., Centeno, A. C. L. S., Capriles, V. D. (2022). Defining Amaranth, Buckwheat and Quinoa Flour Levels in Gluten-Free Bread: A Simultaneous Improvement on Physical Properties, Acceptability and Nutrient Composition through Mixture Design. Foods, 11 (6), 848. https://doi.org/10.3390/foods11060848

- Šmídová, Z., Rysová, J. (2022). Gluten-Free Bread and Bakery Products Technology. Foods, 11 (3), 480. https://doi.org/10.3390/foods11030480

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Maryna Samilyk, Yaroslav Nahornyi, Svetlana Tkachuk, Taisia Ryzhkova, Petro Gurskyi, Liubov Savchuk, Alla Petrenko, Dmytro Hrinchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.