Organizing the automated system of dispatch control over pump units at water pumping stations

DOI:

https://doi.org/10.15587/1729-4061.2024.313531Keywords:

water supply, topology, pump unit, PLC, SCADA, TIA Portal, Sinamics, PIDAbstract

The design and operation of modern dispatch control systems for pumping units involves comprehensive solution to separate engineering, technical, and scientific problems.

The object of research is information processes enabling the operational modes of electrically driven pumping units at water pumping stations.

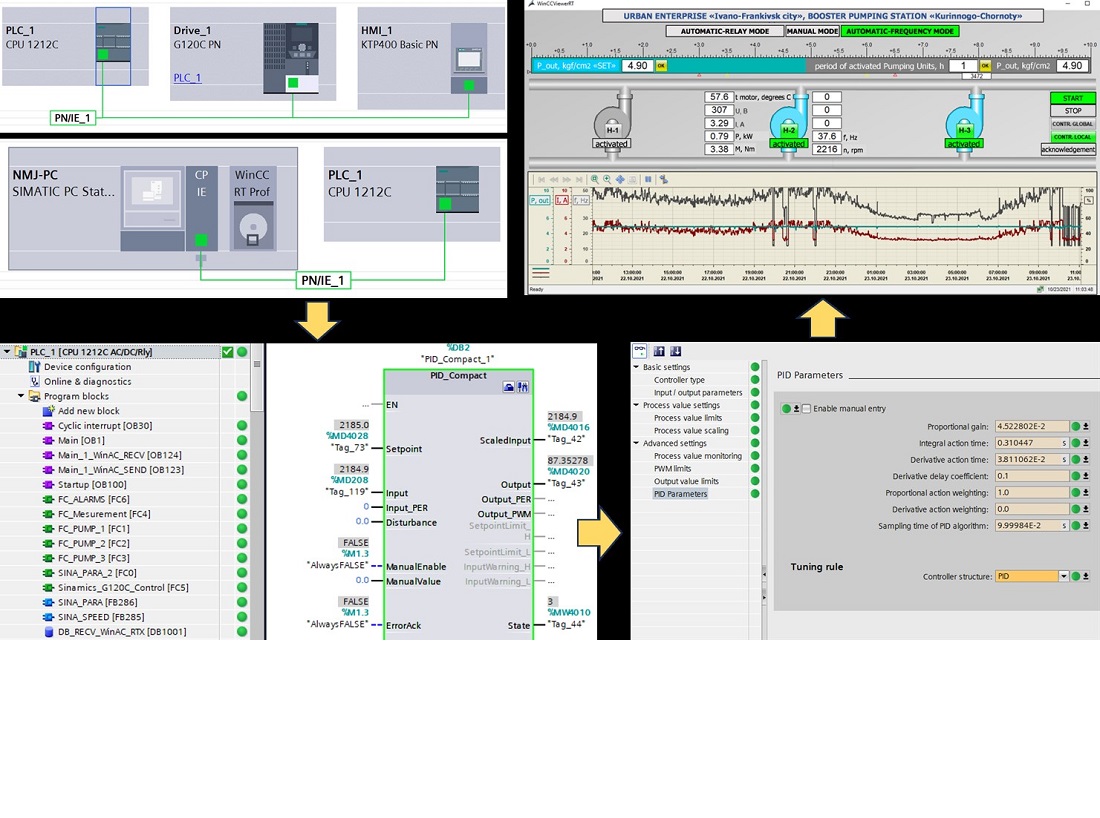

This paper solves the scientific and technical task related to developing topology, hardware, and software tools, control algorithms, dispatch interface, and researching the modes of operation of pumping units in dispatch control systems at water pumping stations.

Algorithms for controlling pumping units have been implemented, the advantage of which is the possibility of automated calculation of parameters for technological PID-controllers, taking into account the current electrical parameters of the frequency-controlled electric drive of pumping units and operating conditions.

The WEB-oriented dispatch interface of the SCADA-based pumping unit control system was designed and tested, which enables control process in real time.

Features of the developed dispatch control system are improved topology, expanded functionality, energy-saving control modes, and the possibility of further modernization based on the principles of standardization and unification of hardware and software tools and design procedures.

The developed dispatch control system for pumping units at water pumping stations has been implemented and is successfully operated at an industrial water supply enterprise.

The results provided for an increase in technical and economic indicators during the operation of technological equipment due to the efficiency of control and management procedures, energy-saving operational modes of the frequency-controlled electric drive of pumping units.

References

- Syufrijal, S., Rif’an, M., Media’s, E. (2019). Construction design system of constant pressure control in water distribution system with PID method using PLC based on IoT. Journal of Physics: Conference Series, 1402 (2), 022060. https://doi.org/10.1088/1742-6596/1402/2/022060

- Ta, V.-P., Truong, D.-N., Nhan, N.-T. (2022). An Innovative Approach for Water Distribution Systems. Intelligent Automation & Soft Computing, 32 (3), 1605–1615. https://doi.org/10.32604/iasc.2022.022374

- Taimaingam, S., Pannil, P. (2024). Comprehensive performance evaluation of profibus and profinet in PLC-based control systems. (2024) ICIC Express Letters. Part B: Applications, 15 (7), 687–699. https://doi.org/10.24507/icicelb.15.07.687

- Vadi, S., Bayindir, R., Toplar, Y., Colak, I. (2022). Induction motor control system with a Programmable Logic Controller (PLC) and Profibus communication for industrial plants – An experimental setup. ISA Transactions, 122, 459–471. https://doi.org/10.1016/j.isatra.2021.04.019

- Kaittan, K. H., Mohammed, S. J. (2024). PLC-SCADA Automation of Inlet Wastewater Treatment Processes: Design, Implementation, and Evaluation. Journal Européen Des Systèmes Automatisés, 57 (3), 787–796. https://doi.org/10.18280/jesa.570317

- Hasan, B., Mohani, S. S.-H., Hussain, S. S., Yasin, S., Alvi, W. A., Saeed, O. (2019). Implementation of Supervisory Control and Data Acquisition - SCADA on a PLC and VFD Controlled Digital Mixing Plant Using TIA Portal. 2019 4th International Conference on Emerging Trends in Engineering, Sciences and Technology (ICEEST), 2, 1–6. https://doi.org/10.1109/iceest48626.2019.8981705

- V.K., A. S., Subramaniam, U., Madurai Elavarasan, R., Raju, K., Shanmugam, P. (2021). Sensorless parameter estimation of VFD based cascade centrifugal pumping system using automatic pump curve adaption method. Energy Reports, 7, 453–466. https://doi.org/10.1016/j.egyr.2021.01.002

- Ahmed, A., Moharam, B., Rashad, E. (2018). Power Saving of Multi Pump-Motor Systems Using Variable Speed Drives. 2018 Twentieth International Middle East Power Systems Conference (MEPCON), 839–844. https://doi.org/10.1109/mepcon.2018.8635157

- Rata, M., Rata, G. (2018). An Efficient Method for Studyingthe Motion Graphs optimization in Electric Drive Systems. 2018 International Conference and Exposition on Electrical And Power Engineering (EPE), ii, 0465–0469. https://doi.org/10.1109/icepe.2018.8559808

- Grecu, D.-L., Popescu, S.-L. (2015). Hard/Soft simulator for electric engines controlled with Siemens automates. 2015 7th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), P-109-P-116. https://doi.org/10.1109/ecai.2015.7301263

- Salkić, A., Muhović, H., Jokić, D. (2022). Siemens S7-1200 PLC DC Motor control capabilities. IFAC-PapersOnLine, 55 (4), 103–108. https://doi.org/10.1016/j.ifacol.2022.06.017

- Zhengtang, L., Xiangdong, L., Lin, Z. (2020). The motor testing system design based on SINAMICS S120 inverter. Journal of Physics: Conference Series, 1550 (4), 042074. https://doi.org/10.1088/1742-6596/1550/4/042074

- Beran, L., Diblik, M. (2016). Indirect torque measurement using industrial vector control frequency converter. 2016 17th International Carpathian Control Conference (ICCC), 1, 48–53. https://doi.org/10.1109/carpathiancc.2016.7501065

- Daniun, M., Awtoniuk, M., Sałat, R. (2017). Implementation of PID autotuning procedure in PLC controller. ITM Web of Conferences, 15, 05009. https://doi.org/10.1051/itmconf/20171505009

- Gabor, G., Livint, G. (2022). Implementation of a PID Controller Using Siemens PLC. 2022 International Conference and Exposition on Electrical And Power Engineering (EPE), 593–596. https://doi.org/10.1109/epe56121.2022.9959869

- Slavicek, L., Balda, P., Schlegel, M. (2021). Comparison of Siemens and REX Controls PI(D) Autotuners. 2021 23rd International Conference on Process Control (PC), 1, 212–218. https://doi.org/10.1109/pc52310.2021.9447480

- Elizabeth, S.-J., Wilson, S.-O., Ana, T.-P., José, T.-C. (2024). Proportional Integral and Derivative Auto Tuning of Industrial Controllers Using the Relay Feedback Method. Good Practices and New Perspectives in Information Systems and Technologies, 96–107. https://doi.org/10.1007/978-3-031-60227-6_9

- SIMATIC STEP 7 Basic/Professional V17 and SIMATIC WinCC V17. Available at: https://support.industry.siemens.com/cs/document/109798671/simatic-step-7-basic-professional-v17-and-simatic-wincc-v17?dti=0&lc=en-UA

- Zamikhovskyi, L. M., Nykolaichuk, M. Ya., Levytskyi, I. T. (2017). Avtomatyzovana systema chastotnoho keruvannia nasosnymy ahrehataty z funktsiyamy dyspetcheryzatsiyi. Intelektualnyi produkt vchenykh, vynakhidnykiv i ratsionalizatoriv Prykarpattia. Shchorichnyi kataloh naivahomishykh vynakhodiv, korysnykh modelei, promyslovykh zrazkiv i ratsionalizatorskykh propozytsiy. Ivano-Frankivsk, 77–81.

- Function Manual. Simatic. Profinet. PROFINET with STEP 7. Available at: https://cache.industry.siemens.com/dl/files/856/49948856/att_897210/v1/profinet_step7_v18_function_manual_en-US_en-US.pdf

- SIMATIC S7 S7-1200 Programmable controller. Available at: https://support.industry.siemens.com/cs/document/109797241/simatic-s7-s7-1200-programmable-controller?dti=0&lc=en-UA

- SINAMICS G: Speed Control of a G110M /G115D/G120 with S7-1200 via PROFINET with Safety Integrated and HMI. Available at: https://support.industry.siemens.com/cs/document/70155469/sinamics-g-speed-control-of-a-g110m-g115d-g120-with-s7-1200-via-profinet-with-safety-integrated-and-hmi?dti=0&lc=en-UA

- Bee, L. (2022). PLC and HMI Development with Siemens TIA Portal. Develop PLC and HMI programs using standard methods and structured approaches with TIA Portal V17. Packt Publishing Ltd., 436.

- PID control with PID_Compact. SIMATIC S7-1200 / S7-1500 + TIA Portal V17. Entry-ID: 100746401, V3.0, 12/2022. Available at: https://cache.industry.siemens.com/dl/files/401/100746401/att_1124946/v2/100746401_S71x00_PidCompact_DOC_V3.0_en.pdf

- PID Control with PID_Compact for SIMATIC S7-1200/S7-1500. Available at: https://support.industry.siemens.com/cs/document/100746401/pid-control-with-pid_compact-for-simatic-s7-1200-s7-1500?dti=0&lc=en-US

- SINAMICS G: Controlling a speed axis with the “SINA_SPEED” block. Available at: https://support.industry.siemens.com/cs/document/109485727/sinamics-g-controlling-a-speed-axis-with-the-%E2%80%9Csina_speed%E2%80%9D-block?dti=0&lc=en-UA

- Closed-Loop Control of Simulated Controlled Systems in the S7-1500 with PID_Compact V2. Available at: https://support.industry.siemens.com/cs/document/79047707/closed-loop-control-of-simulated-controlled-systems-in-the-s7-1500-with-pid_compact-v2?dti=0&lc=en-UA

- Nykolaichuk, M. Ya. (2014). Orhanizatsiya i doslidzhennia elementiv komunikatsiynoho seredovyshcha WEB-oriientovanykh system upravlinnia rozpodilenymy tekhnolohichnymy obiektamy. Metody ta prylady kontroliu yakosti, 2 (33), 133–138. Available at: http://elar.nung.edu.ua/handle/123456789/3344

- SIMATIC HMI WinCC (TIA Portal) WinCC Engineering V17 – Communication. Available at: https://support.industry.siemens.com/cs/document/109794203/simatic-hmi-wincc-(tia-portal)-wincc-engineering-v17-%E2%80%93-communication?dti=0&lc=en-UA

- SIMATIC HMI WinCC (TIA Portal) WinCC Engineering V17 – Options. Available at: https://support.industry.siemens.com/cs/document/109794201/simatic-hmi-wincc-(tia-portal)-wincc-engineering-v17-%E2%80%93-options?dti=0&lc=en-UA

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Leonid Zamikhovskyi, Mykola Nykolaychuk, Ivan Levytskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.