Design of a new film with predefined properties based on chitosan

DOI:

https://doi.org/10.15587/1729-4061.2024.313889Keywords:

biopolymers, chitosan, film-forming solutions, packaging films, combined packaging, bacteriostatic propertiesAbstract

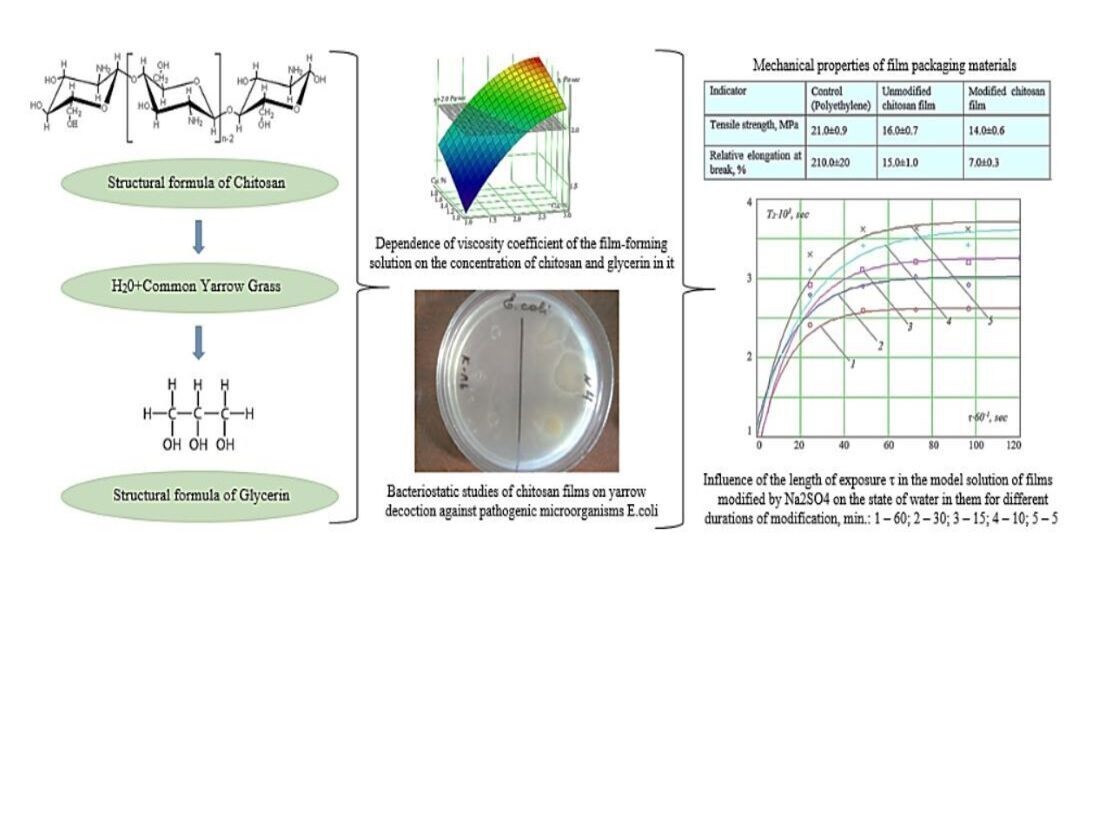

Synthetic and chitosan-based polymer films were selected as the object of this study. Chitosan is a natural non-toxic oligosaccharide of animal origin capable of biological destruction. The task addressed in this work is to design a chitosan-based film with increased bacteriostatic properties for use in combined packaging material as a protective layer. The use of such films would provide for the biodegradability of packaging materials, which could make it possible to reduce the use of synthetic polymers in packaging and improve the environment.

A feature of the proposed method is that a decoction of yarrow grass is used as a chitosan solvent, which leads to the acquisition of bacteriostatic properties by the films. It has been established that the highest bacteriostatic effect is achieved in this case. The results of the research showed a significant growth retardation zone of E. coli, B. cereus, B. subtilis, P. aeruginosa, S. aureus, C. albicans, Saccharomyces and Lactobacillus strains.

The set of studies made it possible to optimize the recipe composition of films based on chitosan (%): chitosan – 2.0...2.5, glycerin – 1.0...1.5, decoction of yarrow grass – 96...97 (according to the ratio of medicinal plant raw materials:water – 1:10).

It was determined that the values of indicators of the destructive stress at the rupture of the designed films (14.0...16.0 MPa) exceed the permissible minimum, which should be 13.7 MPa for polymer films.

The designed films are not intended for independent use as packaging material but should be applied as part of combined packaging as a protective layer.

The scope of application of the current research results is the packaging of food products, namely fruit and vegetable pastes and sauces.

References

- Hafez, A. I. (2023). Chemical Modifications of Chitosan Biopolymer as Poly Electrolyte Membranes for Full Cells: Article review. Water, Energy and Environment Journal, 4 (1), 1–16. Available at: https://www.naturalspublishing.com/Article.asp?ArtcID=27249

- Sutharsan, J., Zhao, J. (2022). Physicochemical and Biological Properties of Chitosan Based Edible Films. Food Reviews International, 39 (9), 6296–6323. https://doi.org/10.1080/87559129.2022.2100416

- Elnaggar, E. M., Abusaif, M. S., Abdel-Baky, Y. M., Ragab, A., Omer, A. M., Ibrahim, I., Ammar, Y. A. (2024). Insight into divergent chemical modifications of chitosan biopolymer: Review. International Journal of Biological Macromolecules, 277, 134347. https://doi.org/10.1016/j.ijbiomac.2024.134347

- Cazón, P., Vázquez, M. (2019). Mechanical and barrier properties of chitosan combined with other components as food packaging film. Environmental Chemistry Letters, 18 (2), 257–267. https://doi.org/10.1007/s10311-019-00936-3

- Lauriano Souza, V. G., Rodrigues, P. F., Duarte, M. P., Fernando, A. L. (2018). Antioxidant Migration Studies in Chitosan Films Incorporated with Plant Extracts. Journal of Renewable Materials. https://doi.org/10.7569/jrm.2018.634104

- Zhang, W., Li, X., Jiang, W. (2020). Development of antioxidant chitosan film with banana peels extract and its application as coating in maintaining the storage quality of apple. International Journal of Biological Macromolecules, 154, 1205–1214. https://doi.org/10.1016/j.ijbiomac.2019.10.275

- Gomes, L. C., Faria, S. I., Valcarcel, J., Vázquez, J. A., Cerqueira, M. A., Pastrana, L. et al. (2021). The Effect of Molecular Weight on the Antimicrobial Activity of Chitosan from Loligo opalescens for Food Packaging Applications. Marine Drugs, 19 (7), 384. https://doi.org/10.3390/md19070384

- Mohammadi, A., Hashemi, M., Masoud Hosseini, S. (2016). Effect of chitosan molecular weight as micro and nanoparticles on antibacterial activity against some soft rot pathogenic bacteria. LWT - Food Science and Technology, 71, 347–355. https://doi.org/10.1016/j.lwt.2016.04.010

- Tan, M., Zhong, X., Xue, H., Cao, Y., Tan, G., Li, K. (2024). Polysaccharides from pineapple peel: Structural characterization, film-forming properties and its effect on strawberry preservation. International Journal of Biological Macromolecules, 279, 135192. https://doi.org/10.1016/j.ijbiomac.2024.135192

- Khanzada, B., Akhtar, N., ul haq, I., Mirza, B., Ullah, A. (2024). Polyphenol assisted nano-reinforced chitosan films with antioxidant and antimicrobial properties. Food Hydrocolloids, 153, 110010. https://doi.org/10.1016/j.foodhyd.2024.110010

- Dubinina, A., Letuta, T., Novikova, V. (2020). Research of the bactericidal properties and toxicity of compositions for stone fruit preservation. Food Science and Technology, 14 (2). https://doi.org/10.15673/fst.v14i2.1721

- Dubinina, A., Letuta, T., Frolova, T., Seliutina, H., Hapontseva, O. (2019). Perspectives of the use of plant raw material extracts for storage of tomatoes. Food Science and Technology, 12 (4). https://doi.org/10.15673/fst.v12i4.1181

- Dubinina, A., Letuta, T., Novikova, V. (2020). Storage of apricots using of medicinal plant extracts. Technical Sciences and Technology, 4 (18), 192–208. https://doi.org/10.25140/2411-5363-2019-4(18)-192-208

- Supplement 11.5. European Pharmacopoeia Online. Available at: https://pheur.edqm.eu/subhome/11-5

- European Pharmacopoeia 10.0. Strasbourg. Available at: https://www.scribd.com/document/508063535/European-Pharmacopoeia-10-0

- Ricarte, R. G., Shanbhag, S. (2024). A tutorial review of linear rheology for polymer chemists: basics and best practices for covalent adaptable networks. Polymer Chemistry, 15 (9), 815–846. https://doi.org/10.1039/d3py01367g

- Tanaka, T. (2000). Experimental Methods in Polymer Science. Academic Press. https://doi.org/10.1016/c2009-0-22460-3

- Diblan, S., Gökkaya Erdem, B., Kaya, S. (2020). Sorption, diffusivity, permeability and mechanical properties of chitosan, potassium sorbate, or nisin incorporated active polymer films. Journal of Food Science and Technology, 57 (10), 3708–3719. https://doi.org/10.1007/s13197-020-04403-8

- Roldán-Ruiz, M. J., Jiménez-Riobóo, R. J., Gutiérrez, M. C., Ferrer, M. L., del Monte, F. (2019). Brillouin and NMR spectroscopic studies of aqueous dilutions of malicine: Determining the dilution range for transition from a “water-in-DES” system to a “DES-in-water” one. Journal of Molecular Liquids, 284, 175–181. https://doi.org/10.1016/j.molliq.2019.03.133

- Pavliuk, R. Yu., Poharska, V. V., Yanytskyi, V. V., Pavliuk, V. A., Sokolova, L. M., Korobets, N. V., Maksymova, N. F. (2013). Tovaroznavstvo ta innovatsiyni tekhnolohiyi pererobky likarsko-tekhnichnoi roslynnoi syrovyny. Ch. 1. Seriya: Ozdorovchi naturalni dobavky ta produkty kharchuvannia. Kharkiv: KhDUKhT, KNTEU, 429.

- de Sousa, D. P., Damasceno, R. O. S., Amorati, R., Elshabrawy, H. A., de Castro, R. D., Bezerra, D. P. et al. (2023). Essential Oils: Chemistry and Pharmacological Activities. Biomolecules, 13 (7), 1144. https://doi.org/10.3390/biom13071144

- Azmir, J., Zaidul, I. S. M., Rahman, M. M., Sharif, K. M., Mohamed, A., Sahena, F. et al. (2013). Techniques for extraction of bioactive compounds from plant materials: A review. Journal of Food Engineering, 117 (4), 426–436. https://doi.org/10.1016/j.jfoodeng.2013.01.014

- Alves, T. F. P., Teixeira, N., Vieira, J., Vicente, A. A., Mateus, N., de Freitas, V., Souza, H. K. S. (2022). Sustainable chitosan packaging films: Green tea polyphenolic extraction strategies using deep eutectic solvents. Journal of Cleaner Production, 372, 133589. https://doi.org/10.1016/j.jclepro.2022.133589

- Xuan Cuong, D., Xuan Hoan, N., Huu Dong, D., Thi Minh Thuy, L., Van Thanh, N., Thai Ha, H. et al. (2020). Tannins: Extraction from Plants. Tannins - Structural Properties, Biological Properties and Current Knowledge. https://doi.org/10.5772/intechopen.86040

- Fraga-Corral, M., García-Oliveira, P., Pereira, A. G., Lourenço-Lopes, C., Jimenez-Lopez, C., Prieto, M. A., Simal-Gandara, J. (2020). Technological Application of Tannin-Based Extracts. Molecules, 25 (3), 614. https://doi.org/10.3390/molecules25030614

- Bonilla, J., Poloni, T., Lourenço, R. V., Sobral, P. J. A. (2018). Antioxidant potential of eugenol and ginger essential oils with gelatin/chitosan films. Food Bioscience, 23, 107–114. https://doi.org/10.1016/j.fbio.2018.03.007

- Mohammed, K., Yu, D., Mahdi, A. A., Zhang, L., Obadi, M., Al-Ansi, W., Xia, W. (2024). Influence of cellulose viscosity on the physical, mechanical, and barrier properties of the chitosan-based films. International Journal of Biological Macromolecules, 259, 129383. https://doi.org/10.1016/j.ijbiomac.2024.129383

- Smoilovska, H. P., Maliuhina, O. O. (2022). Doslidzhennia vmistu dubylnykh rechovyn u travi dereviyu zvychainoho. Suchasni dosiahnennia farmatsevtychnoi spravy, 1, 221–222. Available at: http://dspace.zsmu.edu.ua/handle/123456789/19351

- Wiles, J. L., Vergano, P. J., Barron, F. H., Bunn, J. M., Testin, R. F. (2000). Water Vapor Transmission Rates and Sorption Behavior of Chitosan Films. Journal of Food Science, 65 (7), 1175–1179. https://doi.org/10.1111/j.1365-2621.2000.tb10261.x

- Senra, T. D. A., Campana-Filho, S. P., Desbrières, J. (2018). Surfactant-polysaccharide complexes based on quaternized chitosan. Characterization and application to emulsion stability. European Polymer Journal, 104, 128–135. https://doi.org/10.1016/j.eurpolymj.2018.05.002

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Antonina Dubinina, Valentyna Zaitseva, Svitlana Lehnert, Andriy Vindyk, Oleksander Cherevko, Larysa Tatar, Olena Skyrda, Svitlana Prasol

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.