Improving a technique for producing a polycomponent semi-finished product with high degree of readiness for 3-D printing of functional food

DOI:

https://doi.org/10.15587/1729-4061.2024.313973Keywords:

preliminary heat treatment, polycomponent semi-finished product, functional nutrition, mobile complexes, pastes/fractional powder, model structure, high degree of readinessAbstract

The object of this study is the process of producing polycomponent semi-finished products of a high degree of readiness using a model structure of functional equipment, in particular, based on apple, Jerusalem artichoke, table beet, and sea buckthorn.

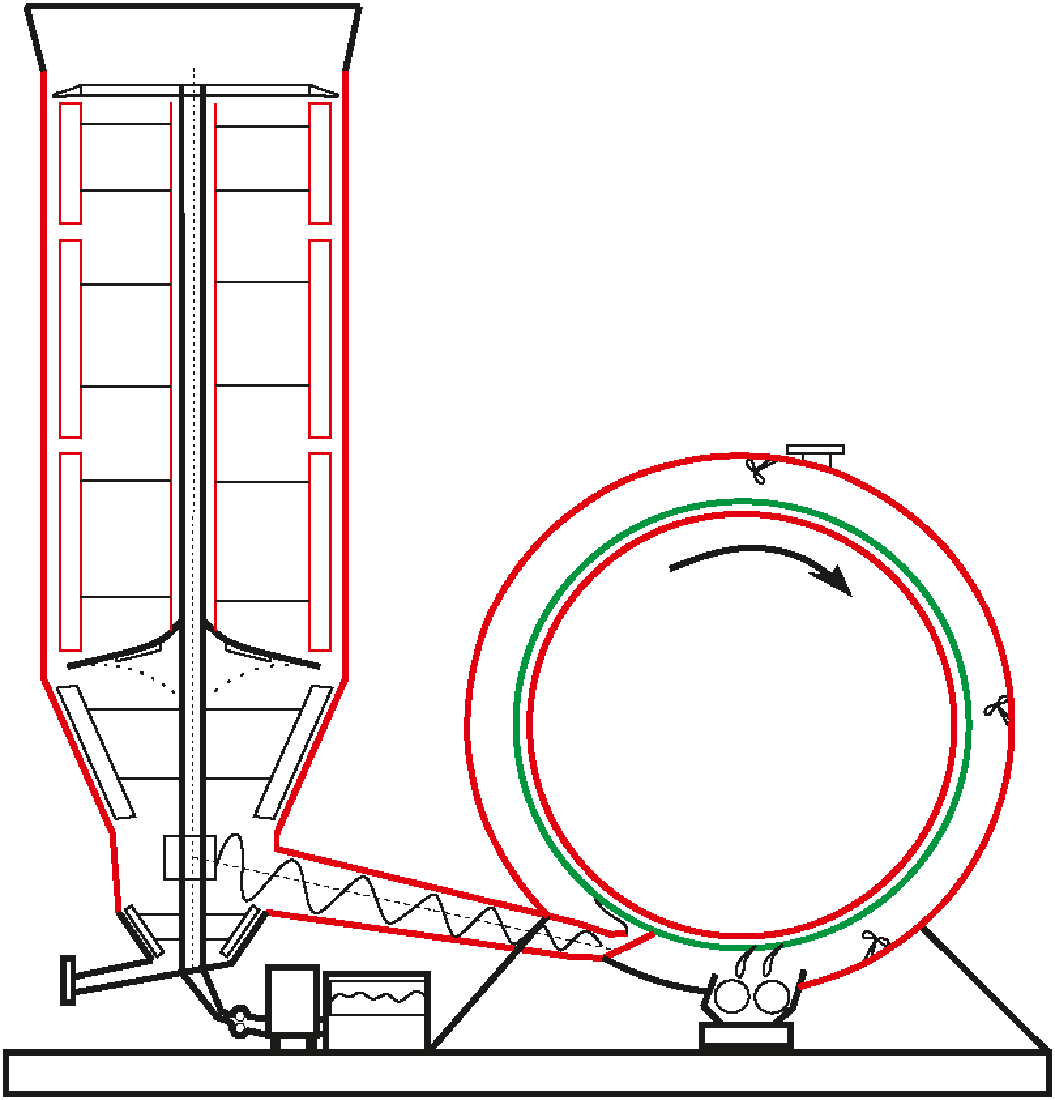

A feature of the improved technique is the implementation of preliminary heat treatment with hot steam of raw materials: apple – 1.0...2.0 min, Jerusalem artichoke – 3...6 min, and table beet – 6...12 min, respectively. Sea buckthorn was not processed, only technological rinsing was used. Grinding of raw materials was carried out on a double grinding machine (apple, Jerusalem artichoke, and table beet – 0.2...0.5 10-3 m, and sea buckthorn – 0.5...1 mm). The combined production of polycomponent semi-finished products of a high degree of readiness (pastes/fractional powder) was implemented using a model structure of functional equipment.

The boiling process in a rotary-film evaporator was carried out at a temperature of 55 °C for 65 seconds to a dry matter content of 25 %. Drying of the cooked multicomponent mass was carried out in a single-drum cylindrical IR dryer at a temperature of 50 °C to a final moisture content of 3...6 % and fractional grinding (0.3...0.6 mm).

The rheological properties of the paste-like multicomponent semi-finished product were determined by the change in dynamic viscosity for composition 2, which is 485 Pa∙s, and in the control sample of applesauce, this indicator is 50 Pa∙s. When boiling in a rotary-film evaporator at a temperature of 55 °C to a content of 30 % of dry substances, there is an increase in the strength of dynamic viscosity by 3.2 times (600 Pa∙s), and in the control (apple paste) this indicator is 178 Pa∙s with a dry matter content of 25 %

References

- Galanakis, C. M., Rizou, M., Aldawoud, T. M. S., Ucak, I., Rowan, N. J. (2021). Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. Trends in Food Science & Technology, 110, 193–200. https://doi.org/10.1016/j.tifs.2021.02.002

- Munekata, P. E. S., Pérez-Álvarez, J. Á., Pateiro, M., Viuda-Matos, M., Fernández-López, J., Lorenzo, J. M. (2021). Satiety from healthier and functional foods. Trends in Food Science & Technology, 113, 397–410. https://doi.org/10.1016/j.tifs.2021.05.025

- Piyush, Kumar, R., Kumar, R. (2020). 3D printing of food materials: A state of art review and future applications. Materials Today: Proceedings, 33, 1463–1467. https://doi.org/10.1016/j.matpr.2020.02.005

- Neamah, H. A., Tandio, J. (2024). Towards the development of foods 3D printer: Trends and technologies for foods printing. Heliyon, 10 (13), e33882. https://doi.org/10.1016/j.heliyon.2024.e33882

- König, L. M., Renner, B. (2019). Boosting healthy food choices by meal colour variety: results from two experiments and a just-in-time Ecological Momentary Intervention. BMC Public Health, 19 (1). https://doi.org/10.1186/s12889-019-7306-z

- Pap, N., Fidelis, M., Azevedo, L., do Carmo, M. A. V., Wang, D., Mocan, A. et al. (2021). Berry polyphenols and human health: evidence of antioxidant, anti-inflammatory, microbiota modulation, and cell-protecting effects. Current Opinion in Food Science, 42, 167–186. https://doi.org/10.1016/j.cofs.2021.06.003

- Ruiz Rodríguez, L. G., Zamora Gasga, V. M., Pescuma, M., Van Nieuwenhove, C., Mozzi, F., Sánchez Burgos, J. A. (2021). Fruits and fruit by-products as sources of bioactive compounds. Benefits and trends of lactic acid fermentation in the development of novel fruit-based functional beverages. Food Research International, 140, 109854. https://doi.org/10.1016/j.foodres.2020.109854

- Luzardo-Ocampo, I., Ramírez-Jiménez, A. K., Yañez, J., Mojica, L., Luna-Vital, D. A. (2021). Technological Applications of Natural Colorants in Food Systems: A Review. Foods, 10 (3), 634. https://doi.org/10.3390/foods10030634

- Schweiggert, R. M. (2018). Perspective on the Ongoing Replacement of Artificial and Animal-Based Dyes with Alternative Natural Pigments in Foods and Beverages. Journal of Agricultural and Food Chemistry, 66 (12), 3074–3081. https://doi.org/10.1021/acs.jafc.7b05930

- Hubbermann, E. M. (2016). Coloring of Low-Moisture and Gelatinized Food Products. Handbook on Natural Pigments in Food and Beverages, 179–196. https://doi.org/10.1016/b978-0-08-100371-8.00008-7

- Mykhailov, V., Zahorulko, A., Zagorulko, A., Liashenko, B., Dudnyk, S. (2021). Method for producing fruit paste using innovative equipment. Acta Innovations, 39, 15–21. https://doi.org/10.32933/actainnovations.39.2

- Zahorulko, A., Zagorulko, A., Kasabova, K., Liashenko, B., Postadzhiev, A., Sashnova, M. (2022). Improving a tempering machine for confectionery masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (116)), 6–11. https://doi.org/10.15587/1729-4061.2022.254873

- De Laurentiis, V., Corrado, S., Sala, S. (2018). Quantifying household waste of fresh fruit and vegetables in the EU. Waste Management, 77, 238–251. https://doi.org/10.1016/j.wasman.2018.04.001

- Silveira, A. C. P. (2015). Thermodynamic and hydrodynamic characterization of the vacuum evaporation process during concentration of dairy products in a falling film evaporator. Food and Nutrition. Available at: https://theses.hal.science/tel-01342521

- Dolores Alvarez, M., Canet, W. (2013). Time-independent and time-dependent rheological characterization of vegetable-based infant purees. Journal of Food Engineering, 114 (4), 449–464. https://doi.org/10.1016/j.jfoodeng.2012.08.034

- Anukiruthika, T., Moses, J. A., Anandharamakrishnan, C. (2020). 3D printing of egg yolk and white with rice flour blends. Journal of Food Engineering, 265, 109691. https://doi.org/10.1016/j.jfoodeng.2019.109691

- Liu, Y., Liang, X., Saeed, A., Lan, W., Qin, W. (2019). Properties of 3D printed dough and optimization of printing parameters. Innovative Food Science & Emerging Technologies, 54, 9–18. https://doi.org/10.1016/j.ifset.2019.03.008

- Piliuhina, I. S., Dobrovolska, O. V., Murlykina, N. V. (2008). Khimiya ta metody doslidzhennia syrovyny ta materialiv. Zahalni osnovy analitychnoi khimiyi. Laboratornyi praktykum. Kharkiv: KhDUKhT, 354.

- Kuznetsova, T. O., Hurikova, I. M. (2010). Kharchova khimiya. Laboratornyi praktykum. Ch. I. Kharkiv: KhDUKhT, 150. Available at: https://repo.btu.kharkov.ua/handle/123456789/4146

- Lashko, N. P., Tkachuk, O. V. (2014). Khimiya kharchovykh dobavok ta vitamaniv. Zaporizhzhia: ZNU, 127. Available at: https://moodle.znu.edu.ua/pluginfile.php/192004/mod_resource/content/1/БП_ХарчДобавки.PDF

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chervonyi, V., Omelchenko, O., Sabadash, S. et al. (2018). Universal multifunctional device for heat and mass exchange processes during organic raw material processing. Eastern-European Journal of Enterprise Technologies, 6 (1 (96)), 47–54. https://doi.org/10.15587/1729-4061.2018.148443

- Zahorulko, A. M., Zahorulko, O. Ye. (2021). Pat. No. 149981 UA. Plivkopodibnyi rezystyvnyi elektronahrivach vyprominiuvalnoho typu. No. u202102839; declareted: 28.05.2021; published: 22.12.2021. Available at: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=279804

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

- Cherevko, O., Mikhaylov, V., Zahorulko, A., Zagorulko, A., Gordienko, I. (2021). Development of a thermal-radiation single-drum roll dryer for concentrated food stuff. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 25–32. https://doi.org/10.15587/1729-4061.2021.224990

- Cherevko, A., Mayak, O., Kostenko, S., Sardarov, A. (2019). Experimental and simulation modeling of the heat exchanche process while boiling vegetable juice. Progressive technique and technologies of food production enterprises, catering business and trade, 1 (29), 75–85. https://doi.org/10.5281/zenodo.3263532

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chuiko, L., Yakovets, L., Pugach, A. et al. (2022). Improving the production technology of functional paste-like fruit-and-berry semi-finished products. Eastern-European Journal of Enterprise Technologies, 4 (11 (118)), 43–52. https://doi.org/10.15587/1729-4061.2022.262924

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Andrii Zahorulko, Iryna Voronenko, Iryna Bozhydai, Aleksey Pogarskiy, Eldar Ibaiev, Nataliia Ponomarenko, Olena Bereza, Oleksandr Khytko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.