Improving the soil bin for studying rotary tools taking into account the kinematic features of interaction with the soil

DOI:

https://doi.org/10.15587/1729-4061.2024.315127Keywords:

soil bin, rotary implement, kinematic parameter, trajectory, soil-tool interaction, tillageAbstract

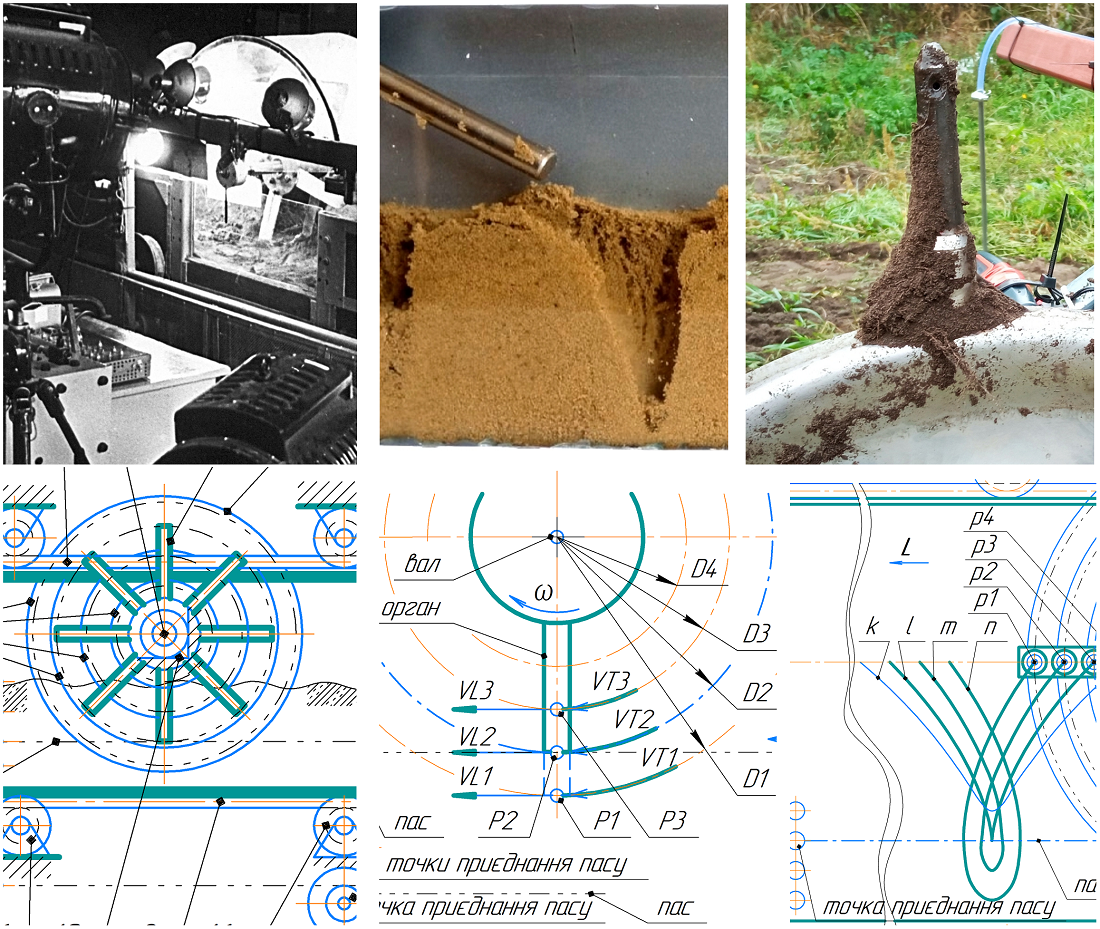

The object of this study is experimental equipment in the form of a soil bin intended for scientific and educational investigation of rotary tools.

The task solved was to clarify the specificity of rotary tools operation and to design a small-sized soil bin taking into account this specificity. The data collected during experimental research and theoretical analysis confirmed the determining influence of the kinematic parameter on the indicators of interaction between the rotary tool and soil.

As a result of the research, a concept was proposed and a soil mini channel was designed, which makes it possible to investigate the process mechanics and to perform graphic modeling.

The result relates to the fact that the mediator of motion transmission during the experiments was a ground trough, and the drive belt is rearranged in engagement with pulleys of different diameters. This provides a different ratio of linear movement of the trough and rotation of the working body.

The peculiarity of the design is the combination of variable movable troughs and graphic screens with a stationary position of the rotor. The design provides simplicity and visibility of the assignment of different values of the kinematic parameter.

A special feature is the modularity of the structure. This makes it possible to conduct research with variable troughs with different soil composition and immediately acquire a graphic interpretation of the kinematic mode on the screen. This implementation of the soil mini bin simplifies the observation and recording of the result of interaction between the rotor and model environment.

The field of practical use is scientific research in the area of agricultural engineering. The data obtained can be used to improve existing tools. The research process is part of the educational process at the agricultural university

References

- Kornienko, S., Pashenko, V., Melnik, V., Kharchenko, S., Khramov, N. (2016). Developing the method of constructing mathematical models of soil condition under the action of a wedge. Eastern-European Journal of Enterprise Technologies, 5 (7 (83)), 34–43. https://doi.org/10.15587/1729-4061.2016.79912

- Vetohin, V. I., Panov, I. M., Shmonin, V. A., YUzbashev, V. A. (2009).Tyagovo-privodnye kombinirovannye pochvoobrabatyvayuschie mashiny: Teoriya, raschet, rezul'taty ispytaniy. Kyiv: FENYKS, 264. Available at: https://dspace.pdau.edu.ua/handle/123456789/15056

- Roozbahani, A., Mardani, A., Jokar, R., Taghavifar, H. (2014). Evaluating and measuring the performance parameters of agricultural wheels. International Journal of Biological, Life and Agricultural Sciences. https://doi.org/10.5281/zenodo.1326793

- Lajani, A., Nikbakht, A. M., Askari, M., Salar, M. R. (2024). Design, construction and evaluation of a miniature soil bin plus predicting the measured parameters during primary tests using ANFIS. Heliyon, 10 (1), e24041. https://doi.org/10.1016/j.heliyon.2024.e24041

- Godwin, R. J., Spoor, G. (1977). Soil failure with narrow tines. Journal of Agricultural Engineering Research, 22 (3), 213–228. https://doi.org/10.1016/0021-8634(77)90044-0

- Mardani, A., Golanbari, B. (2024). Indoor measurement and analysis on soil-traction device interaction using a soil bin. Scientific Reports, 14 (1). https://doi.org/10.1038/s41598-024-59800-2

- Upadhyay, G., Raheman, H. (2018). Performance of combined offset disc harrow (front active and rear passive set configuration) in soil bin. Journal of Terramechanics, 78, 27–37. https://doi.org/10.1016/j.jterra.2018.04.002

- Upadhyay, G., Raheman, H. (2020). Effect of velocity ratio on performance characteristics of an active-passive combination tillage implement. Biosystems Engineering, 191, 1–12. https://doi.org/10.1016/j.biosystemseng.2019.12.010

- Celik, A., Ozturk, I., Way, T. R. (2008). A theoretical approach for determining irregularities of the bottom of the tillage layer caused by horizontal axis rotary tillers. Agricultural Engineering International: the CIGR Ejournal, X, 1–9. Available at: https://cigrjournal.org/index.php/Ejounral/article/view/1168

- Hendrick, J. G., Gill, W. R. (1971). Rotary tiller design parameters: Part II. Depth of tillage. Transactions of the ASAE, 14 (4), 675–678. https://doi.org/10.13031/2013.38365

- Ani, O. A., Uzoejinwa, B. B., Ezeama, A. O., Onwualu, A. P., Ugwu, S. N., Ohagwu, C. J. (2018). Overview of soil-machine interaction studies in soil bins. Soil and Tillage Research, 175, 13–27. https://doi.org/10.1016/j.still.2017.08.002

- Vetokhin, V., Negrebetsky, I., Ryzhkova, T., Salo, Y., Voznyuk, T. (2021). Analytical review of technical solutions of needle rotary tools for applying liquid fertilizers to the soil layer. Technical and Technological Aspects of Development and Testing of New Machinery and Technologies for Agriculture of Ukraine, 29 (43). https://doi.org/10.31473/2305-5987-2021-1-29(43)-9

- Hendrick, J. G., Gill, W. R. (1974). Rotary Tiller Design Parameters Part IV-Blade Clearance Angle. Transactions of the ASAE, 17 (1), 0004-0007. https://doi.org/10.13031/2013.36771

- Sheichenko, V., Dudnikov, I., Shevchuk, V., Kuzmich, A. (2019). The analytical assessment of the needle harrow interaction with the soil. Ukrainian Black Sea Region Agrarian Science, 103 (3). https://doi.org/10.31521/2313-092x/2019-3(103)-13

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Volodymyr Vetokhin, Stanislav Popov, Tetiana Ryzhkova, Igor Negrebetskyi, Serhii Leshchenko, Volodymyr Amosov, Yurii Machok, Dmytro Petrenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.