Defining indicators for the anaerobic fermentation process of aquaculture wastewater sediments

DOI:

https://doi.org/10.15587/1729-4061.2024.317019Keywords:

anaerobic fermentation of sediment, specific yield of biomethane, recirculation system of aquaculture, biomethaneAbstract

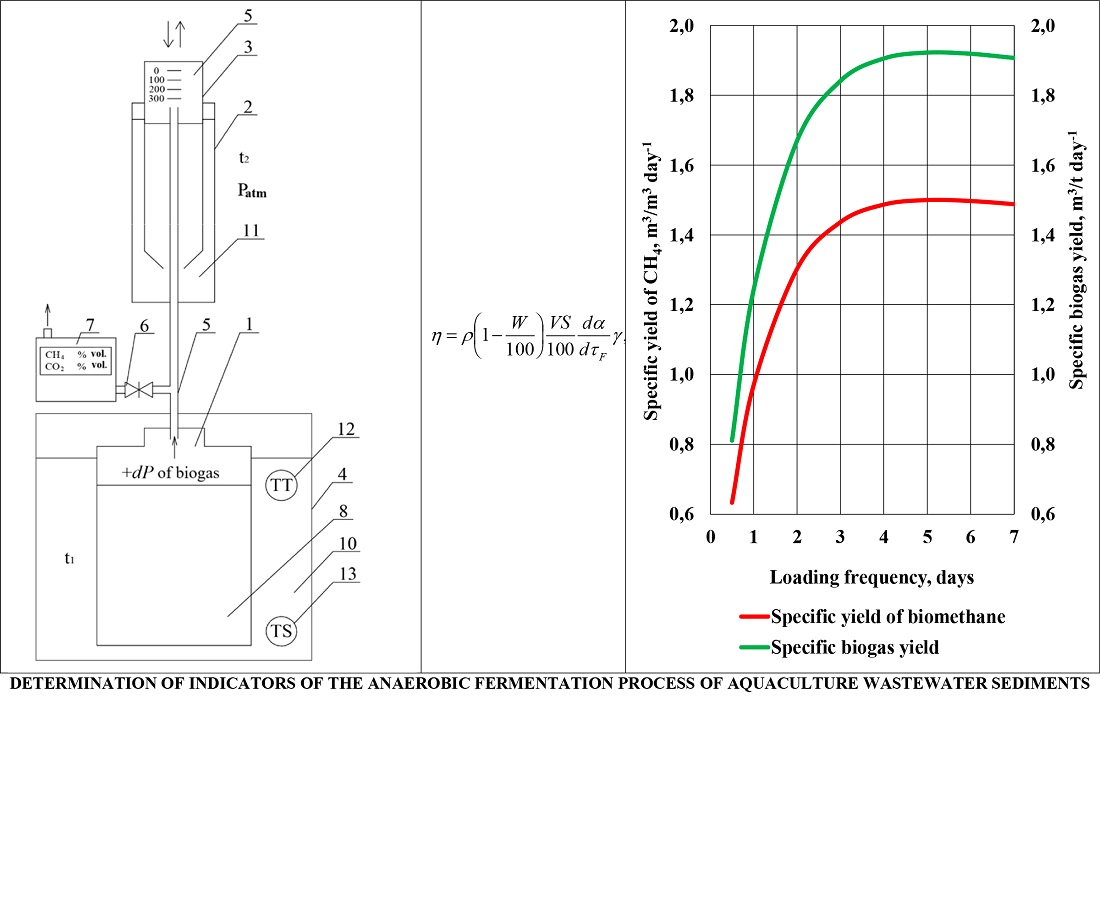

The object of this study is the process of anaerobic fermentation of wastewater sludge from aquaculture. It was established that the exponential dependence adequately describes the experimental data on the change in the level of decomposition of dry organic matter (DOM) and the specific yield of biomethane per unit of decomposed DOM of aquaculture wastewater sediment depending on the time of anaerobic fermentation. The maximum level of DOM decomposition during anaerobic fermentation achieved in 38 days was 0.74 relative units at a process speed of 0.108 relative units per day. The integrated level of DOM decomposition over 21 days of anaerobic fermentation can reach only 0.43 relative units, and the integrated level of DOM decomposition is set at the level of 0.033 relative units per day. The output of biogas and biomethane during anaerobic fermentation over 21 days of anaerobic fermentation reached 4.083 and 2.627 l, respectively. At the same time, the concentration of biomethane in biogas on day 7 of fermentation reached 74‒75 % and remained at this level until day 21. The maximum level of specific yield of biomethane during anaerobic fermentation reached on day 38 was 803.936 ml in terms of normal conditions per gram of decomposed DOM with a rate of change of the specific yield of biomethane of 0.207 ml in terms of normal conditions per gram of decomposed DOM per day. The integrated specific yield of biomethane over 21 days of anaerobic fermentation could reach 580‒590 ml in terms of normal conditions per gram of decomposed DOM. With a fermentation time of 21 days, the specific output of biomethane has an optimal value depending on the periodicity of loading the reactor, which is 1.48‒1.49 m3 of biomethane per one m3 of biomass in the reactor in one day with a periodicity of loading the reactor once per time from 4.5 to 6 days. The research results could be used to determine the volume of biomethane production and electricity based on it during the anaerobic fermentation of aquaculture wastewater sludge

References

- Xu, J., Wang, J., Lin, S., Hou, L., Ma, S., Lv, Y., Chen, R. et al. (2023). The effect of novel aquaculture mode on phosphorus sorption-release in pond sediment. Science of The Total Environment, 905, 167019. https://doi.org/10.1016/j.scitotenv.2023.167019

- Jia, S., Wang, L., Zhang, J., Zhang, L., Ma, F., Huang, M. et al. (2022). Comparative study on the morphological characteristics and nutritional quality of largemouth bass (Micropterus salmoides) cultured in an aquaculture system using land-based container with recycling water and a traditional pond system. Aquaculture, 549, 737721. https://doi.org/10.1016/j.aquaculture.2021.737721

- Horstmann, P., Alliney, N., Eding, E. H., Kals, J., Prakash, S., Staessen, T. W. O. et al. (2024). Practical implications of lowering dietary starch content on waste management in recirculating aquaculture systems operated with drum filtration or sedimentation in yellowtail kingfish (Seriola lalandi). Aquaculture, 584, 740587. https://doi.org/10.1016/j.aquaculture.2024.740587

- Li, H., Cui, Z., Cui, H., Bai, Y., Yin, Z., Qu, K. (2023). Hazardous substances and their removal in recirculating aquaculture systems: A review. Aquaculture, 569, 739399. https://doi.org/10.1016/j.aquaculture.2023.739399

- Sarkar, S., Kamilya, D., Mal, B. C. (2007). Effect of geometric and process variables on the performance of inclined plate settlers in treating aquacultural waste. Water Research, 41 (5), 993–1000. https://doi.org/10.1016/j.watres.2006.12.015

- Cripps, S. J., Bergheim, A. (2000). Solids management and removal for intensive land-based aquaculture production systems. Aquacultural Engineering, 22 (1-2), 33–56. https://doi.org/10.1016/s0144-8609(00)00031-5

- Yang, H., Tan, T., Du, X., Feng, Q., Liu, Y., Tang, Y. et al. (2025). Advancements in freshwater aquaculture wastewater management: A comprehensive review. Aquaculture, 594, 741346. https://doi.org/10.1016/j.aquaculture.2024.741346

- Gebauer, R., Eikebrokk, B. (2006). Mesophilic anaerobic treatment of sludge from salmon smolt hatching. Bioresource Technology, 97 (18), 2389–2401. https://doi.org/10.1016/j.biortech.2005.10.008

- Akizuki, S., Suzuki, H., Fujiwara, M., Toda, T. (2023). Impacts of steam explosion pretreatment on semi-continuous anaerobic digestion of lignin-rich submerged macrophyte. Journal of Cleaner Production, 385, 135377. https://doi.org/10.1016/j.jclepro.2022.135377

- da Borso, F., Chiumenti, A., Fait, G., Mainardis, M., Goi, D. (2021). Biomethane Potential of Sludges from a Brackish Water Fish Hatchery. Applied Sciences, 11 (2), 552. https://doi.org/10.3390/app11020552

- Ferreira, R. C. B. (2012). Anaerobic digestion of sludge from marine recirculation aquaculture systems. Integrated Master in Environmental Engineering – 2011/2012. Faculty of Engineering of University of Porto. Porto, 90. Available at: https://repositorio-aberto.up.pt/bitstream/10216/65569/1/000154211.pdf

- Zhang, X., Spanjers, H., van Lier, J. B. (2013). Potentials and limitations of biomethane and phosphorus recovery from sludges of brackish/marine aquaculture recirculation systems: A review. Journal of Environmental Management, 131, 44–54. https://doi.org/10.1016/j.jenvman.2013.09.016

- Lobanov, V., De Vrieze, J., Joyce, A. (2023). Simultaneous biomethane production and nutrient remineralization from aquaculture solids. Aquacultural Engineering, 101, 102328. https://doi.org/10.1016/j.aquaeng.2023.102328

- Pesante, G., Bolzonella, D., Jelic, A., Frison, N. (2024). Upgrading biogas plants to produce microbial proteins for aquaculture feed. Journal of Cleaner Production, 459, 142559. https://doi.org/10.1016/j.jclepro.2024.142559

- Righetti, E., Nortilli, S., Fatone, F., Frison, N., Bolzonella, D. (2020). A Multiproduct Biorefinery Approach for the Production of Hydrogen, Methane and Volatile Fatty Acids from Agricultural Waste. Waste and Biomass Valorization, 11 (10), 5239–5246. https://doi.org/10.1007/s12649-020-01023-3

- Golub, G., Tsyvenkova, N., Holubenko, A., Chuba, V., Tereshchuk, M. (2021). Investigation of substrate mixing process in rotating drum reactor. INMATEH Agricultural Engineering, 63 (1), 51–60. https://doi.org/10.35633/inmateh-63-05

- Choudhury, A., Lepine, C., Witarsa, F., Good, C. (2022). Anaerobic digestion challenges and resource recovery opportunities from land-based aquaculture waste and seafood processing byproducts: A review. Bioresource Technology, 354, 127144. https://doi.org/10.1016/j.biortech.2022.127144

- Golub, G., Kukharets, S., Zavadska, O., Marus, O. (2019). Determination of the rate of organic biomass decomposition in biogas reactors with periodic loading. International Journal of Renewable Energy Research, 9 (4), 1741–1750. https://doi.org/10.20508/ijrer.v9i4.10163.g7777

- Meyer, A. K. P., Ehimen, E. A., Holm-Nielsen, J. B. (2018). Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass and Bioenergy, 111, 154–164. https://doi.org/10.1016/j.biombioe.2017.05.013

- Ahlberg-Eliasson, K., Nadeau, E., Levén, L., Schnürer, A. (2017). Production efficiency of Swedish farm-scale biogas plants. Biomass and Bioenergy, 97, 27–37. https://doi.org/10.1016/j.biombioe.2016.12.002

- Halder, N. (2017). Thermophilic Biogas Digester for Efficient Biogas Production from Cooked Waste and Cow Dung and Some Field Study. International Journal of Renewable Energy Research, 7 (3), 1062–1073. https://doi.org/10.20508/ijrer.v7i3.5844.g7137

- Cucchiella, F., D’Adamo, I., Gastaldi, M. (2019). An economic analysis of biogas-biomethane chain from animal residues in Italy. Journal of Cleaner Production, 230, 888–897. https://doi.org/10.1016/j.jclepro.2019.05.116

- Torrellas, M., Burgos, L., Tey, L., Noguerol, J., Riau, V., Palatsi, J. et al. (2018). Different approaches to assess the environmental performance of a cow manure biogas plant. Atmospheric Environment, 177, 203–213. https://doi.org/10.1016/j.atmosenv.2018.01.023

- Ishikawa, S., Iwabuchi, K., Takahashi, K., Hara, R., Kita, H. (2019). Performance evaluation based on long-term operation results of biogas plant for livestock manure management. Engineering in Agriculture, Environment and Food, 12 (2), 155–161. https://doi.org/10.1016/j.eaef.2018.12.003

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Gennadii Golub, Oksana Yaremenko, Petro Kucheruk, Oleh Marus, Nataliya Tsyvenkova, Volodymyr Nadykto, Viacheslav Chuba, Yaroslav Yarosh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.