Devising approaches to adjusting a strength gain by modified white cements with different c3a content

DOI:

https://doi.org/10.15587/1729-4061.2024.317201Keywords:

Abstract

The object of this study is the mechanism for adjusting a strength gain by modified systems based on white cements with different C3A content.

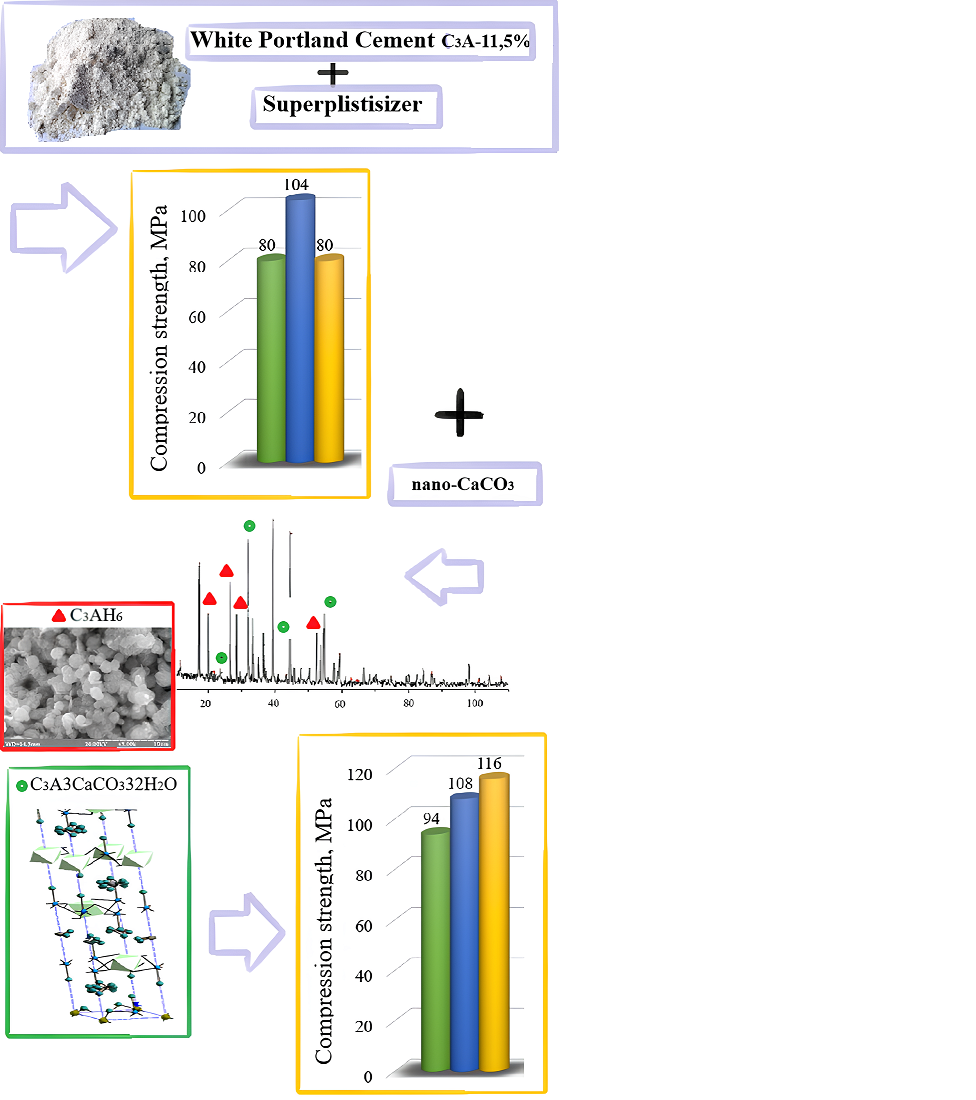

Since white cements have an increased content of the C3A mineral, they are characterized by a drop in strength of up to 10 % in the late stages of hardening. To stabilize the properties of such cements, it is advisable to use modifying additives.

It has been established that when a plasticizing additive with a high C3A content is introduced into cement in a small amount (0.5...1 %), as a result of chemical interaction with the mineral C3A, its residue in the liquid phase is not enough to disperse silicate phases. This reduces viscosity of the system. That subsequently leads to a decline in the strength of cement stone, up to 15 %. At the same time, the addition of a plasticizing additive to a system with a low content of C3A turns out to be more effective even at a lower dosage.

Modification of cement systems with nano-CaCO3 additives helps stabilize the phase composition of new formations and guarantees the durability of the resulting cement stone. Nano-CaCO3 changes the composition of new formations toward more thermodynamically stable compounds. The introduction of a nano-CaCO3 additive leads to a significant increase in the rate of hydration and creates conditions for the formation of carbonate ettringite. The latter contributes to the directed synthesis of low-base fibrous hydrosilicate phases, including tobermorite, and prevents the conversion of hydroaluminate phases, which eliminates the decline in strength in white cements with an increased content of C3A.

Applying modified systems will make it possible to stabilize the strength characteristics of not only white but also colored cements, the introduction of pigments to which leads to a decrease in their strength. This approach will make it possible to effectively use such systems as a basis for decorative concrete and mortars

References

- Mohtasham Moein, M., Rahmati, K., Saradar, A., Moon, J., Karakouzian, M. (2024). A Critical Review Examining the Characteristics of Modified Concretes with Different Nanomaterials. Materials, 17 (2), 409. https://doi.org/10.3390/ma17020409

- Shen, D., Kang, J., Shao, H., Liu, C., Li, M., Chen, X. (2023). Cracking failure behavior of high strength concrete containing nano-CaCO3 at early age. Cement and Concrete Composites, 139, 104996. https://doi.org/10.1016/j.cemconcomp.2023.104996

- Camiletti, J., Soliman, A. M., Nehdi, M. L. (2012). Effects of nano- and micro-limestone addition on early-age properties of ultra-high-performance concrete. Materials and Structures, 46 (6), 881–898. https://doi.org/10.1617/s11527-012-9940-0

- Mardani-Aghabaglou, A., Kankal, M., Nacar, S., Felekoğlu, B., Ramyar, K. (2021). Assessment of cement characteristics affecting rheological properties of cement pastes. Neural Computing and Applications, 33 (19), 12805–12826. https://doi.org/10.1007/s00521-021-05925-8

- Karakuzu, K. Kobya, V., Mardani, A. (2022). Determination of Optimum Water Reducing Admixture Dosage and Water Content in the Measurement of Rheological Parameters of Paste Mixtures Having Different C3A Ratios. European Journal of Science and Technology, 37, 17–20. https://doi.org/10.31590/ejosat.1125646

- Kim, T.-H., Ye, B., Jeong, B., Lee, M.-J., Song, A., Cho, I. et al (2024). Influence of CaCO3 on Density and Compressive Strength of Calcium Aluminate Cement-Based Cementitious Materials in Binder Jetting. Materials, 17 (14), 3463. https://doi.org/10.3390/ma17143463

- Matschei, T., Lothenbach, B., Glasser, F. P. (2007). The role of calcium carbonate in cement hydration. Cement and Concrete Research, 37 (4), 551–558. https://doi.org/10.1016/j.cemconres.2006.10.013

- Lothenbach, B., Le Saout, G., Gallucci, E., Scrivener, K. (2008). Influence of limestone on the hydration of Portland cements. Cement and Concrete Research, 38 (6), 848–860. https://doi.org/10.1016/j.cemconres.2008.01.002

- Bentz, D. P., Ardani, A., Barrett, T., Jones, S. Z., Lootens, D., Peltz, M. A. et al. (2015). Multi-scale investigation of the performance of limestone in concrete. Construction and Building Materials, 75, 1–10. https://doi.org/10.1016/j.conbuildmat.2014.10.042

- Yeşilmen, S., Al-Najjar, Y., Balav, M. H., Şahmaran, M., Yıldırım, G., Lachemi, M. (2015). Nano-modification to improve the ductility of cementitious composites. Cement and Concrete Research, 76, 170–179. https://doi.org/10.1016/j.cemconres.2015.05.026

- Bentz, D. P., Sato, T., de la Varga, I., Weiss, W. J. (2012). Fine limestone additions to regulate setting in high volume fly ash mixtures. Cement and Concrete Composites, 34 (1), 11–17. https://doi.org/10.1016/j.cemconcomp.2011.09.004

- Salama, K. K., Ali, M. F., El-Sheikh, S. M. (2018). The different influence of nano materials on pigments. Scientific Culture, 4 (3), 1–7. https://doi.org/10.5281/zenodo.1409798

- Pushkarova, K., Kochevykh, M., Honchar, O., Hadaichuk, D. (2024). Features of Hardening and Utilization of Modern Cement Compositions with Nanomodifying Additives For Repair And Restoration Works. International Journal of Conservation Science, 15 (SI), 157–168. https://doi.org/10.36868/ijcs.2024.si.13

- Kropyvnytska, T. P., Sanytskyi, M. A., Heviuk, I. M. (2013). Vplyv karbonatnykh dobavok na vlastyvosti portlandtsementu kompozytsiynoho. Visnyk Natsionalnoho universytetu "Lvivska politekhnika" Teoriya i praktyka budivnytstva, 755, 214–220. Available at: https://science.lpnu.ua/sctp/all-volumes-and-issues/volume-755-2013-1/vpliv-karbonatnih-dobavok-na-vlastivosti

- Sharma, H., Ashish, D. K. (2023). Nano CaCO3 for enhancing properties of cement-based materials: a comprehensive review. Journal of Sustainable Cement-Based Materials, 12 (12), 1475–1494. https://doi.org/10.1080/21650373.2023.2233512

- Wu, Z., Khayat, K. H., Shi, C., Tutikian, B. F., Chen, Q. (2021). Mechanisms underlying the strength enhancement of UHPC modified with nano-SiO2 and nano-CaCO3. Cement and Concrete Composites, 119, 103992. https://doi.org/10.1016/j.cemconcomp.2021.103992

- Pushkarova, K., Sheinich, L., Gadaichuk, D., Kushnierova, L., Mazur, V. (2021). Crystallo-chemical aspects of the processes for structure formation of white portlandcement in the presence of nanocarbonate additives. Science and Construction, 30 (4), 36–45. https://doi.org/10.33644/2313-6679-15-2021-4

- Ghosal, M., Kumar Chakraborty, A. (2022). Superplasticizer compatibility with cement properties – A study. Materials Today: Proceedings, 56, 568–573. https://doi.org/10.1016/j.matpr.2022.02.386

- Ramachandran, V. S., Malhotra, V. M. (1996). Superplasticizers. Concrete Admixtures Handbook, 410–517. https://doi.org/10.1016/b978-081551373-5.50011-8

- Kakali, G., Tsivilis, S., Aggeli, E., Bati, M. (2000). Hydration products of C3A, C3S and Portland cement in the presence of CaCO3. Cement and Concrete Research, 30 (7), 1073–1077. https://doi.org/10.1016/s0008-8846(00)00292-1

- Feldman, R. F., Ramachandran, V. S., Sereda, P. J. (1965). Influence of CaCO3 on the Hydration of 3CaO•Al2O3. Journal of the American Ceramic Society, 48 (1), 25–30. https://doi.org/10.1111/j.1151-2916.1965.tb11787.x

- Runčevski, T., Dinnebier, R. E., Magdysyuk, O. V., Pöllmann, H. (2012). Crystal structures of calcium hemicarboaluminate and carbonated calcium hemicarboaluminate from synchrotron powder diffraction data. Acta Crystallographica Section B Structural Science, 68 (5), 493–500. https://doi.org/10.1107/s010876811203042x

- Ji, G., Chi, H., Sun, K., Peng, X., Cai, Y. (2024). Effect of limestone waste on the hydration and microstructural properties of cement-based materials. Construction and Building Materials, 443, 137784. https://doi.org/10.1016/j.conbuildmat.2024.137784

- Janotka, I., Mojumdar, S. C. (2007). Degree of hydration in cement paste and C3A-sodium carbonate-water systems. Journal of Thermal Analysis and Calorimetry, 90 (3), 645–652. https://doi.org/10.1007/s10973-007-8517-6

- Ruiz-Agudo, C., Cölfen, H. (2024). Exploring the Potential of Nonclassical Crystallization Pathways to Advance Cementitious Materials. Chemical Reviews, 124 (12), 7538–7618. https://doi.org/10.1021/acs.chemrev.3c00259

- Pushkarova, K., Tereshchenko, L. (2024). Study of the combined influence of inorganic pigments and nanocarbonate additives on the synthesis of the strength of decorative cements. Resource-saving materials, structures, buildings and structures, 45, 68–75. https://doi.org/10.31713/budres.v0i45.08

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Kateryna Pushkarova, Liliia Kushnierova, Larysa Tereshchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.