Identifying the effect of sodium dodecylbenzene sulfonate surfactant and dispersed pcb-based particles as a novel heat treatment quenchant on the hardness of S45C medium carbon steel

DOI:

https://doi.org/10.15587/1729-4061.2024.317205Keywords:

Abstract

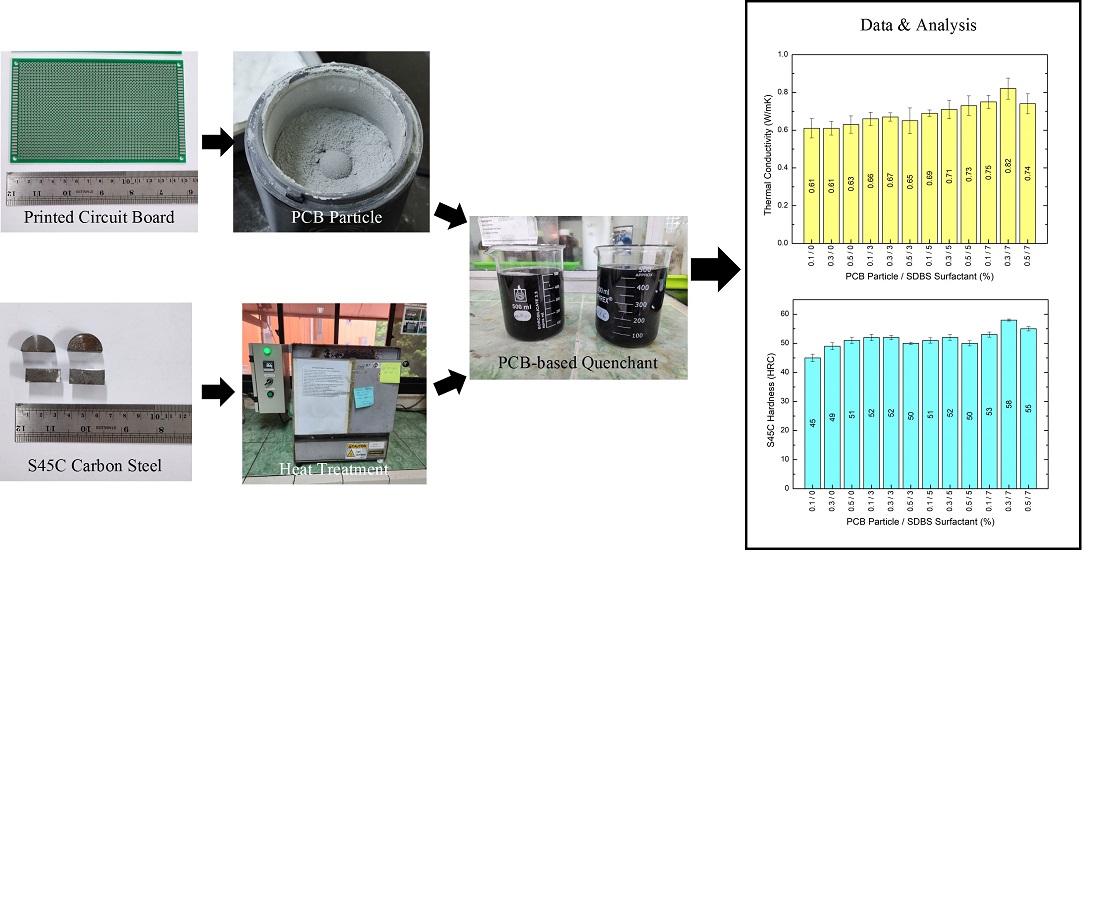

In this study, the effect of Sodium Dodecylbenzene Sulfonate (SDBS) addition as a surfactant on the performance of the Printed Circuit Board (PCB) particle-dispersed quenchant in terms of thermal conductivity, particle stability, the microstructure and hardness of S45C medium carbon steel has been investigated. Conventional quenchants have fixed, uncontrollable cooling rates. Adding solid particles creates a thermal bridge, enabling adjustable cooling rates to address this limitation. The solid particles in the quenchant were synthesized from PCB. The surfactant helps to improve particle dispersion and avoid agglomeration by modifying the surface tension between the particles and the fluid. PCB particle-dispersed media have been prepared and used as quenchants to study the effect of PCB dispersion, and its concentrations on the heat transfer rate during quenching. Based on this research results, particle stability measurement by zeta potential shows the stability improvement up to –21.53 mV after 7wt % of surfactant addition, compared to distilled water. Due to the better particle dispersion, the thermal conductivity of the quenchant is also improved by 39 %, maximized at 0.82 W/mK when compared with the quenchant without surfactant at only 0.61 W/mK. Furthermore, the quenched steel hardness also increases by 29 %, maximized at 58 HRC at 7wt % surfactant and 0.3wt % PCB particles composition. The Dispersed PCB particles in the quenchant allow the heat flow from high to lower temperature efficiently. The experimental results show that a water-based quench medium with PCB particle dispersion is an alternative quench medium to obtain a more controlled cooling rate in steel heat treatment and is one solution for utilizing PCB electronic waste

References

- Putra, W. N., Pramaditya, P., Pramuka, P., Mochtar, M. A. (2018). Effect of Sub Zero Treatment on Microstructures, Mechanical Properties, and Dimensional Stability of AISI D2 Cold Work Tool Steel. Materials Science Forum, 929, 136–141. https://doi.org/10.4028/www.scientific.net/msf.929.136

- Araghchi, M., Mansouri, H., Vafaei, R. (2016). The Effects of Quenching Media and Aging on Residual Stress and Mechanical Properties of 2024 Aluminum Alloy. Proceedings of Iran International Aluminum Conference (IIAC2016). Available at: https://www.researchgate.net/profile/Masoud-Araghchi/publication/303034408_The_Effects_of_Quenching_Media_and_Aging_on_Residual_Stress_and_Mechanical_Properties_of_2024_Aluminum_Alloy/links/5735e4eb08ae9ace840ae642/The-Effects-of-Quenching-Media-and-Aging-on-Residual-Stress-and-Mechanical-Properties-of-2024-Aluminum-Alloy.pdf

- Eissa, A. H., Hasan, H. S. (2020). Simulation and Experimental Investigation Quenching Behavior of Medium Carbon Steel in Water Based Multi Wall Carbon Nanotube Nanofluids. Al-Nahrain Journal for Engineering Sciences, 23 (2), 137–143. https://doi.org/10.29194/njes.23020137

- Babu, K., Arularasan, R., Srinath Ramkumar, S. (2017). Quenching performance of AISI 1010 in CNT nanofluids. Materials Today: Proceedings, 4 (10), 11044–11049. https://doi.org/10.1016/j.matpr.2017.08.065

- Mairizal, A. Q., Sembada, A. Y., Tse, K. M., Rhamdhani, M. A. (2021). Electronic waste generation, economic values, distribution map, and possible recycling system in Indonesia. Journal of Cleaner Production, 293, 126096. https://doi.org/10.1016/j.jclepro.2021.126096

- Ordóñez, F., Chejne, F., Pabón, E., Cacua, K. (2020). Synthesis of ZrO2 nanoparticles and effect of surfactant on dispersion and stability. Ceramics International, 46 (8), 11970–11977. https://doi.org/10.1016/j.ceramint.2020.01.236

- Yahya, S. S., Harjanto, S., Putra, W. N., Ramahdita, G., Kresnodrianto, Mahiswara, E. P. (2018). Characterization and observation of water-based nanofluids quench medium with carbon particle content variation. AIP Conference Proceedings, 1964, 020006. https://doi.org/10.1063/1.5038288

- Jehhef, K. A., Al Abas Siba, M. A. (2019). Effect of surfactant addition on the nanofluids properties: a review. Acta Mechanica Malaysia, 2 (2), 01–19. https://doi.org/10.26480/amm.02.2019.01.19

- Khaleduzzaman, S. S., Mahbubul, I. M., Shahrul, I. M., Saidur, R. (2013). Effect of particle concentration, temperature and surfactant on surface tension of nanofluids. International Communications in Heat and Mass Transfer, 49, 110–114. https://doi.org/10.1016/j.icheatmasstransfer.2013.10.010

- Putra, W. N., Ariati, M., Suharno, B., Noviyanto, A., Riko, I. M. (2024). Effect of Multi-walled Carbon Nanotube and Polyethylene Glycol Addition in Nanofluid Quench Medium for Steel Heat Treatment Application. International Journal of Technology, 15 (2), 364. https://doi.org/10.14716/ijtech.v15i2.6690

- Hubau, A., Chagnes, A., Minier, M., Touzé, S., Chapron, S., Guezennec, A.-G. (2019). Recycling-oriented methodology to sample and characterize the metal composition of waste Printed Circuit Boards. Waste Management, 91, 62–71. https://doi.org/10.1016/j.wasman.2019.04.041

- Qiu, R., Lin, M., Qin, B., Xu, Z., Ruan, J. (2021). Environmental-friendly recovery of non-metallic resources from waste printed circuit boards: A review. Journal of Cleaner Production, 279, 123738. https://doi.org/10.1016/j.jclepro.2020.123738

- Choi, S. U. S., Eastman, J. A. (1995). Enhancing thermal conductivity of fluids with nanoparticles. No. ANL/MSD/CP-84938; CONF-951135-29. Argonne National Lab., IL (United States), 9. Available at: https://ecotert.com/pdf/196525_From_unt-edu.pdf

- Yang, S., Jiang, J., Wang, Q. (2020). The novel application of nonmetals from waste printed circuit board in high-performance thermal management materials. Composites Part A: Applied Science and Manufacturing, 139, 106096. https://doi.org/10.1016/j.compositesa.2020.106096

- Jadhav, U., Hocheng, H. (2015). Hydrometallurgical Recovery of Metals from Large Printed Circuit Board Pieces. Scientific Reports, 5 (1). https://doi.org/10.1038/srep14574

- Cacua, K., Ordoñez, F., Zapata, C., Herrera, B., Pabón, E., Buitrago-Sierra, R. (2019). Surfactant concentration and pH effects on the zeta potential values of alumina nanofluids to inspect stability. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 583, 123960. https://doi.org/10.1016/j.colsurfa.2019.123960

- Zhang, J., Ge, D., Wang, X., Wang, W., Cui, D., Yuan, G. et al. (2021). Influence of Surfactant and Weak-Alkali Concentrations on the Stability of O/W Emulsion in an Alkali-Surfactant–Polymer Compound System. ACS Omega, 6 (7), 5001–5008. https://doi.org/10.1021/acsomega.0c06142

- Paramashivaiah, B. M., Rajashekhar, C. R. (2016). Studies on effect of various surfactants on stable dispersion of graphene nano particles in simarouba biodiesel. IOP Conference Series: Materials Science and Engineering, 149, 012083. https://doi.org/10.1088/1757-899x/149/1/012083

- Jafarian, H. R., Sabzi, M., Mousavi Anijdan, S. H., Eivani, A. R., Park, N. (2021). The influence of austenitization temperature on microstructural developments, mechanical properties, fracture mode and wear mechanism of Hadfield high manganese steel. Journal of Materials Research and Technology, 10, 819–831. https://doi.org/10.1016/j.jmrt.2020.12.003

- Yaghoobi, F., Jamaati, R., Jamshidi Aval, H. (2021). Simultaneous enhancement of strength and ductility in ferrite-martensite steel via increasing the martensite fraction. Materials Chemistry and Physics, 259, 124204. https://doi.org/10.1016/j.matchemphys.2020.124204

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Wahyuaji Narottama Putra, Myrna Ariati, Eddy Sumarno Siradj, Bambang Suharno

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.