Defining patterns in the fire protection of wood with reactive coating

DOI:

https://doi.org/10.15587/1729-4061.2024.317334Keywords:

reactive coating, wood preservatives, wood surface treatment, volatile combustion products, swelling of the coatingAbstract

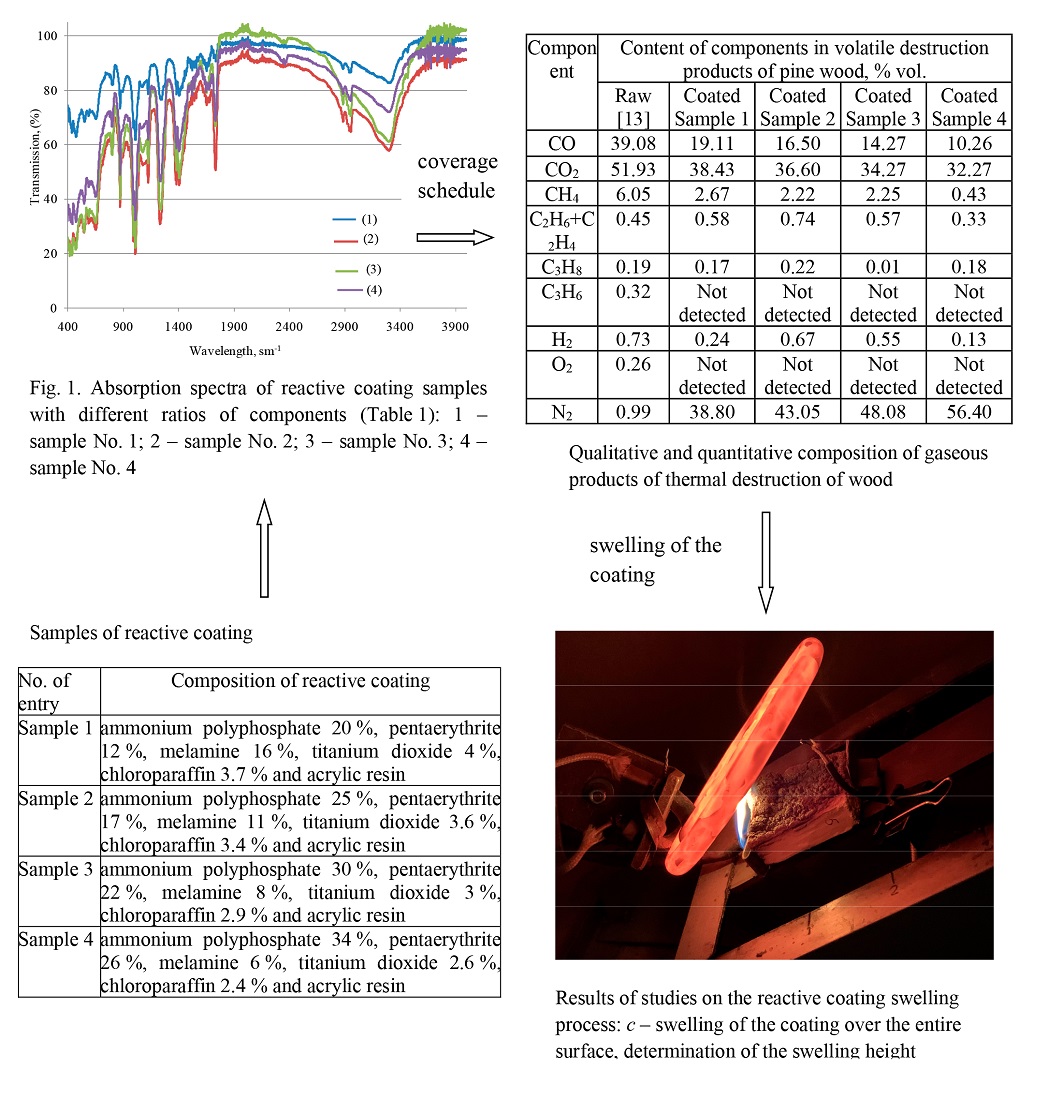

An issue related to using a weatherproof reactive coating for fire protection of wood is to ensure resistance to high-temperature flame via application technology. Therefore, the object of research was the fire-retardant properties of reactive coating based on mixtures of organic-inorganic substances during interaction with flame. It has been proven that the samples of the reactive coating represent an accumulation of fine-dispersed equally sized substances surrounded by a polymer binder, which begin to decompose under thermal action; in particular, ammonium polyphosphate decomposes and releases phosphoric acid. That leads to the dehydration of pentaerythrite with the formation of soot while the decomposition of melamine is accompanied by the release of non-combustible gases that cause the soot to foam, thereby forming foamcoke. The mechanism of fire protection of wood has been established, which is related to the decomposition of flame retardants under the influence of temperature, the release of non-combustible gases, and the formation of a non-flammable coke residue. Thus, when the content of ammonium polyphosphate and pentaerythrite in the reactive coating was increased by 5 %, the volume of combustible gases decreased by more than 11 %, and the volume of nitrogen increased by more than 10 %. When their content was increased by 14 %, the volume of combustible gases decreased by more than 2 times, and the volume of nitrogen increased by more than 1.45 times. That also affected the formation of a foamcoke layer, which was recorded at the lowest content of ammonium polyphosphate at the level of 12 mm and increased for higher values up to 15.5 mm, and the multiplicity of foam increased by 1.25 times. The practical significance is that the results are taken into account when designing the reactive coating. Thus, there are reasons to assert the possibility of targeted regulation of the wood protection process by applying coatings capable of forming a protective layer on the surfacev

References

- Demirhan, Y., Yurtseven, R., Usta, N. (2021). The effect of boric acid on flame retardancy of intumescent flame retardant polypropylene composites including nanoclay. Journal of Thermoplastic Composite Materials, 36 (3), 1187–1214. https://doi.org/10.1177/08927057211052327

- Jung, D., Bhattacharyya, D. (2021). Combined effect of silicate coating and phosphate loading on the performance improvement of a keratinous fiber-based flame retardant. Chemical Engineering Journal, 424, 130484. https://doi.org/10.1016/j.cej.2021.130484

- Bachtiar, E., Kurkowiak, K., Yan, L., Kasal, B., Kolb, T. (2019). Thermal Stability, Fire Performance, and Mechanical Properties of Natural Fibre Fabric-Reinforced Polymer Composites with Different Fire Retardants. Polymers, 11 (4), 699. https://doi.org/10.3390/polym11040699

- Liu, J., Qi, P., Chen, F., Zhang, J., Li, H., Sun, J. et al. (2024). A universal eco-friendly flame retardant strategy for polylactic acid fabrics and other polymer substrates. International Journal of Biological Macromolecules, 260, 129411. https://doi.org/10.1016/j.ijbiomac.2024.129411

- Huang, H., Deng, J., Xu, B., Kang, L. (2024). Synergistic effect of coal gangue on intumescent flame retardants. Journal of Physics: Conference Series, 2819 (1), 012052. https://doi.org/10.1088/1742-6596/2819/1/012052

- Hansen-Bruhn, I., Hull, T. R. (2023). Flammability and burning behaviour of fire protected timber. Fire Safety Journal, 140, 103918. https://doi.org/10.1016/j.firesaf.2023.103918

- Markert, F., González, I., De La Parra Rogero, C., Hosta, E. S. (2023). Protection of pre-treated wood and construction materials using intumescent coatings. Journal of Physics: Conference Series, 2654 (1), 012084. https://doi.org/10.1088/1742-6596/2654/1/012084

- Sarathiraja, M., Devanathan, S., Kannan, M. (2020). Tuning parameters for flame-retardant coatings on wood and polymer. Materials Today: Proceedings, 24, 1138–1146. https://doi.org/10.1016/j.matpr.2020.04.427

- Ou, M., Cui, J., Zhao, Z., Li, R., Guan, H., Liu, L. et al. (2023). Solvent-free intumescent fire protection epoxy coatings with excellent smoke suppression, toxicity reduction, and durability enabled by a micro/nano-structured P/N/Si-containing flame retardant. Progress in Organic Coatings, 183, 107762. https://doi.org/10.1016/j.porgcoat.2023.107762

- Bourbigot, S. (2024). Intumescence-Based Flame Retardant. Fire Retardancy of Polymeric Materials, 116–146. https://doi.org/10.1201/9781003380689-7

- Wu, D., Yang, M., Wu, T., Shen, Y., Wang, T. (2024). Green one-step modification of spent coffee grounds as synergistic bio-based flame retardant for waterborne epoxy resin. Progress in Organic Coatings, 191, 108409. https://doi.org/10.1016/j.porgcoat.2024.108409

- Ding, Y., Chen, Z., Tang, C., Huang, W., Ren, X., Zhou, K., Hu, H. (2024). Development of a pyrolysis reaction model for epoxy based flame retardant composites: Relationship between pyrolysis behavior and material composition. Chemical Engineering Journal, 495, 153628. https://doi.org/10.1016/j.cej.2024.153628

- Tsapko, Y., Tsapko, А. (2017). Establishment of the mechanism and fireproof efficiency of wood treated with an impregnating solution and coatings. Eastern-European Journal of Enterprise Technologies, 3 (10 (87)), 50–55. https://doi.org/10.15587/1729-4061.2017.102393

- Pettersen, R. C. (1984). The Chemical Composition of Wood. The Chemistry of Solid Wood, 57–126. https://doi.org/10.1021/ba-1984-0207.ch002

- Broido, A. (1969). A simple, sensitive graphical method of treating thermogravimetric analysis data. Journal of polymer science part a-2: polymer physics, 7 (10), 1761–1773. https://doi.org/10.1002/pol.1969.160071012

- Kryvenko, P., Tsapko, Y., Guzii, S., Kravchenko, A. (2016). Determination of the effect of fillers on the intumescent ability of the organic-inorganic coatings of building constructions. Eastern-European Journal of Enterprise Technologies, 5 (10 (83)), 26–31. https://doi.org/10.15587/1729-4061.2016.79869

- Tsapko, Y., Tsapko, А., Likhnyovskyi, R., Sukhanevych, M., Zapolskiy, L., Illiuchenko, P., Bedratiuk, O. (2024). Establishing patterns in reducing fire-dangerous properties of sip panels fire-protected with reactive coating. Eastern-European Journal of Enterprise Technologies, 1 (10 (127)), 47–54. https://doi.org/10.15587/1729-4061.2024.298266

- Tsapko, Y., Likhnyovskyi, R., Tsapko, А., Bielikova, K., Poteriaiko, S., Illiuchenko, P., Bondarenko, O. (2023). Determining patterns in the formation of an insulation layer of foam coke when protecting concrete against fire by reactive coating. Eastern-European Journal of Enterprise Technologies, 6 (10 (126)), 65–72. https://doi.org/10.15587/1729-4061.2023.293685

- Tsapko, Y., Likhnyovskyi, R., Tsapko, А., Kovalenko, V., Slutska, O., Illiuchenko, P. et al. (2023). Determining the thermal-physical characteristics of a coke foam layer in the fire protection of cable articles with foaming coating. Eastern-European Journal of Enterprise Technologies, 2 (10 (122)), 22–30. https://doi.org/10.15587/1729-4061.2023.275550

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Yuriy Tsapko, Tetiana Tkachenko, Аleksii Tsapko, Ruslan Likhnyovskyi, Maryna Sukhanevych, Yuliia Bereznutska, Vitally Prisyazhnuk, Ruslan Klymas, Alisa Rotova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.