Development of a new method for stone coal converting into a liquid high-temperature heat carrier based on energy factors

DOI:

https://doi.org/10.15587/1729-4061.2024.318568Keywords:

synthesis gas, liquid high-temperature heat carrier, hard coal, three-zone reactor, mineral componentAbstract

The object of this study is coal processing with synthesis gas as the target product. The experimental technology employs a reactor with a liquid high-temperature heat carrier. The technological advancement allows ecological and safe transformation of hard raw material – hard coal.

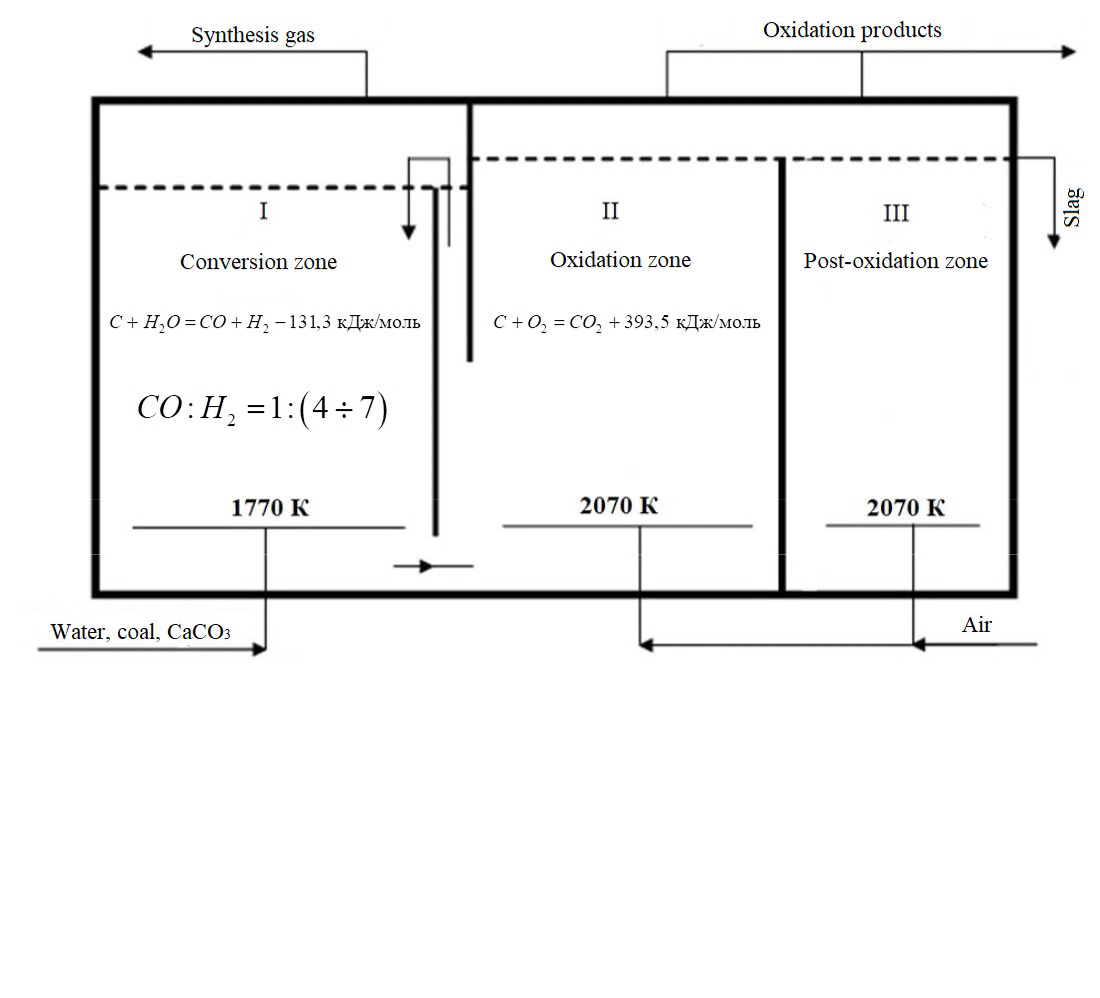

Hard, brown, and salty coal contains quite a lot of mineral impurities. Thermodynamic analysis of chemical transformations of coal according to its content has been carried out. The analysis was performed under the conditions of the new technology. The technology makes it possible to work simultaneously with solid, liquid, and gas structures. The main technological parameters are considered to be atmospheric pressure, temperature from 1073 to 1373 K, composition and height of the heat carrier in the reactor. The optimal temperature conditions for the process in the melt were revealed. The research was related to the characteristics and properties of liquid high-temperature heat carrier. Two types of laboratory reactors were studied. The composition and volume of the liquid heat carrier contributes to a stable and balanced progress of the target process. The proposed scheme of a reactor with a liquid high-temperature heat carrier for the coal gasification process allows for an environmentally friendly process. The designed scheme contains three zones of the process: conversion, oxidation, and post-oxidation. The reactor scheme is quite simple in structure. The technology in liquid high-temperature heat carrier involves one heat carrier for three reactor zones. The target product of processing is synthesis gas. Synthesis gas can be used directly as a target product with hydrogen being an alternative energy source. Synthesis gas as a raw material can be used to obtain hydrocarbons, separate use of substances for various industries and transformation into various compounds of organic and inorganic synthesis

References

- Book: Essentials of Environmental Science (CK-12) (2024). Available at: https://eng.libretexts.org/Bookshelves/Environmental_Engineering_(Sustainability_and_Conservation)/Book%3A_Essentials_of_Environmental_Science_(CK-12)/14%3A_Untitled_Chapter_14/14.02%3A_New_Page

- Tashcheev, Iu. V. (2015). Energy efficiency: renewable and non-renewable energy. Vestnik sotcialno-ekonomicheskikh issledovanii, 2 (57), 169–177. Available at: https://www.researchgate.net/publication/348778074_ENERGOEFEKTIVNIST_VIDNOVLUVANI_TA_NEVIDNOVLUVANI_DZERELA_ENERGII

- Zubtsov, E. Y., Hlykyn, M. A., Hlykyna, Y. M. (2006). Hazyfykatsyia uhlei v zhydkom visokotemperaturnom teplonosytele s poluchenyem syntez-haza. Visnyk Natsionalnoho tekhnichnoho universytetu «KhPI», 11, 67–74.

- Falshtynskyi, V., Saik, P., Lozynskyi, V., Dychkovskyi, R., Petlovanyi, M. (2018). Innovative aspects of underground coal gasification technology in mine conditions. Mining of Mineral Deposits, 12 (2), 68–75. https://doi.org/10.15407/mining12.02.068

- Rosen, M., Scott, D. (1987). An energy-exergy analysis of the Koppers-Totzek process for producing hydrogen from coal☆. International Journal of Hydrogen Energy, 12 (12), 837–845. https://doi.org/10.1016/0360-3199(87)90105-4

- Svitlyi, Yu. H., Krut, O. A., Biletskyi, V. S. (2013). Ukrainian Experience of Brown Coal Treatment to Coal Water Slurry. Energotekhnologii i resursosberezhenie, 2, 5–10. Available at: http://nbuv.gov.ua/UJRN/ETRS_2013_2_3

- Korchevoy, Yu., Pivnyak, G. (2006). Advanced coal technology for energy branch. Available at: https://scinn.org.ua/sites/default/files/pdf/2006/N2/2_06_53.pdf

- Gupta, S., De, S. (2021). Investigation of cold flow hydrodynamics in a dual fluidized bed for gasification of high-ash coal. Powder Technology, 384, 564–574. https://doi.org/10.1016/j.powtec.2021.02.030

- Haponych, L. S., Melnyk, Z. P., Ivashchenko, N. V., Cherniavskyi, M. V. (2008). Tekhnolohii pererobky nyzkoiakisnoho vuhillia dlia enerhoustanovok maloi ta serednoi potuzhnosti. Kharchova promyslovist, 7, 102–105.

- Abaimov, N., Ryzhkov, A., Tuponogov, V., Simbiriatin, L., Dubinin, A., Ding, L., Alekseenko, S. (2023). Steam Gasification in a Fluidized Bed with Various Methods of In-Core Coal Treatment. Axioms, 12 (6), 587. https://doi.org/10.3390/axioms12060587

- Tontu, M. (2020). An investigation of performance characteristics and energetic efficiency of vertical roller coal mill. International Journal of Coal Preparation and Utilization, 41 (4), 248–262. https://doi.org/10.1080/19392699.2020.1799200

- Reddy, P. J. (2013). Coal treatment and emissions control technologies. Clean Coal Technologies for Power Generation. CRC Press, 91–116. https://doi.org/10.1201/b15512-11

- Kim, T., Park, S. D., Lee, U. D., Park, B. C., Park, K. I., Hong, J. (2021). Thermodynamic analysis of the 2nd generation pressurized fluidized-bed combustion cycle utilizing an oxy-coal boiler and a gasifier. Energy, 236, 121471. https://doi.org/10.1016/j.energy.2021.121471

- Ma, S., Liu, C., Sun, Y., Gong, C., Qu, B., Ma, L., Tang, R. (2019). Advanced treatment technology for FGD wastewater in coal-fired power plants: current situation and future prospects. Desalination and Water Treatment, 167, 122–132. https://doi.org/10.5004/dwt.2019.24630

- Wu, X., Yu, H., Wu, P., Wang, C., Chen, H., Sun, Y., Zheng, H. (2024). A Gasification Technology to Combine Oil Sludge with Coal–Water Slurry: CFD Analysis and Performance Determination. Fluid Dynamics & Materials Processing, 20 (7), 1481–1498. https://doi.org/10.32604/fdmp.2024.047092

- Saranchuk, V. I., Iliashov, M. O., Oshovskyi, V. V., Biletskyi, V. S. (2008). Osnovy khimii i fizyky horiuchykh kopalyn. Donetsk: Skhidnyi vydavnychyi dim, 640. Available at: https://repository.kpi.kharkov.ua/items/3a9a7bd0-32c9-430e-954b-6bea78416749

- Zubtsov, E. Y., Hlykyn, M. A., Hlykyna, Y. M., Tarasov, V. Yu. (2007) Hazyfykatsyia uhlia razlychnoho fraktsyonnoho sostava v zhydkom visokotemperaturnom teplonosytele. Visnyk Skhidnoukrainskoho natsionalnoho universytetu im. V. Dalia, 11 (2), 52–55.

- Radovenchyk, V. M., Ivanenko, O. I., Radovenchyk, Ya. V., Krysenko, T. V. (2020). Zastosuvannia ferytnykh materialiv v protsesakh ochyshchennia vody. Kyiv: Kondor-Vydavnytstvo, 215. Available at: https://eco-paper.kpi.ua/CONTENT/literatyra/ferity_mono.pdf

- Natriiu khloryd. Farmatsevtychna entsyklopediia. Available at: https://www.pharmencyclopedia.com.ua/article/1207/natriyu-xlorid

- Zubtsov, E. Y., Tarasov, V. Yu., Brodskyi, O. L., Kravchenko, I. V. (2017) Parova konversiia hazovoho vuhillia v rozplavi v statsionarnomu ta protochnomu rezhymi. Visnyk Skhidnoukrainskoho natsionalnoho universytetu im. V. Dalia, 5 (235), 50–55.

- Glikina, I., Kudryavtsev, S., Zubcov, I. E., Luhovskoi, I. A. (2018). The perspective technologies for the processing of fossil fuels. Resources and resourcesaving technologies in mineral mining and processing. Petroșani: Universitas Publishing, 78–127.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Irene Glikina, Yevhen Zubtsov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.