Power and emission estimation of plastic waste pyrolysis-derived fuel blends in internal combustion engines

DOI:

https://doi.org/10.15587/1729-4061.2024.318593Keywords:

plastic waste, pyrolysis, fuel mixture, power, exhaust gas, types of plasticAbstract

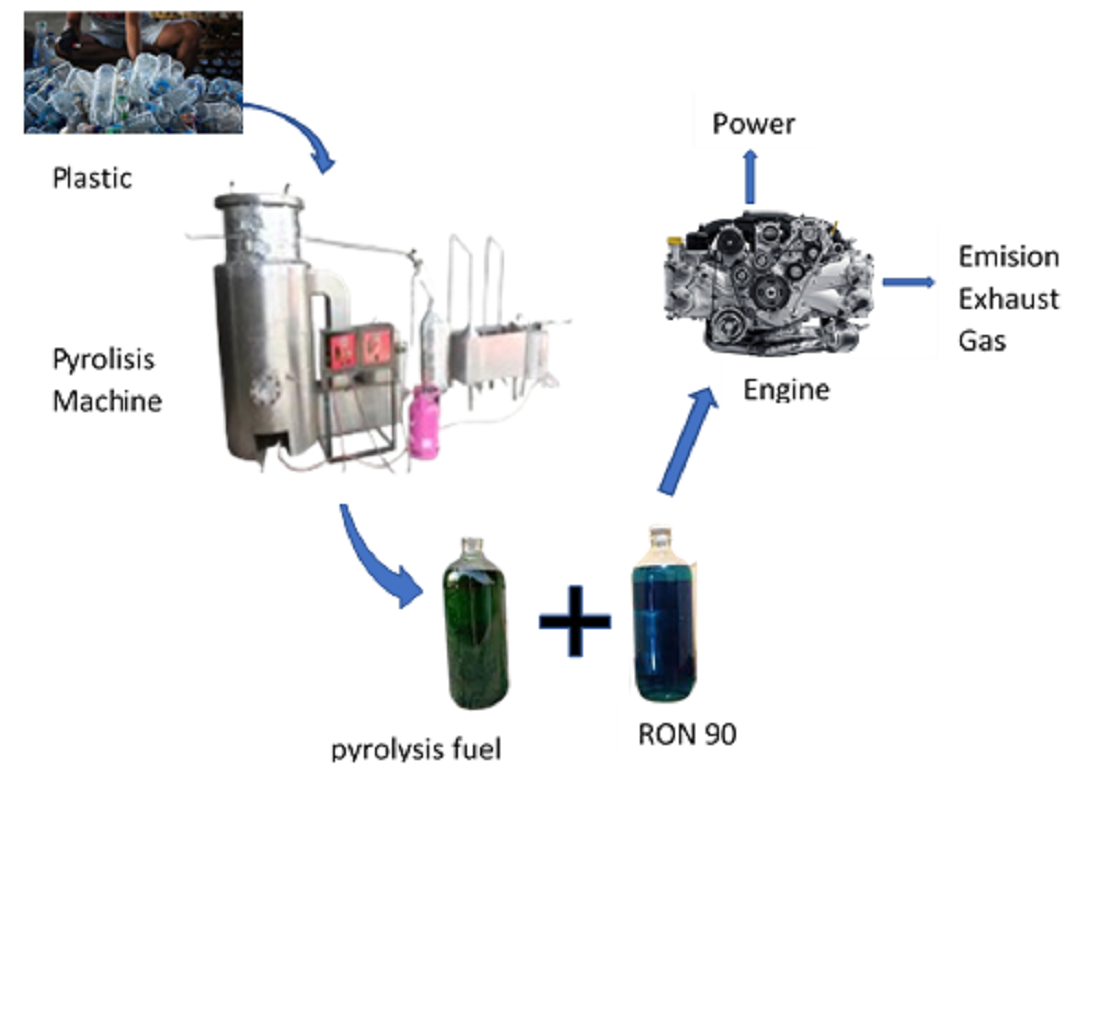

Energy, especially from fossil fuels, is essential for everyday life, while plastic waste is an increasing environmental threat. Plastic waste disposal methods such as landfilling and burning cause pollution. Therefore, a process is needed that converts plastic waste into fuel. The object of the study is the engine performance. The problem to be solved is the relationship between the use of a mixture of fossil fuels and pyrolysis fuel on the performance of internal combustion engines.

This research uses a systematic data collection process to obtain accurate and reliable results. The necessary equipment, including a dynamometer and gas analyzer, was prepared, and the engine was warmed up to a stable operating temperature of 80 °C. The motorbike is then positioned on the dynamometer with the rear tires aligned and the front tires secured to prevent movement. Data collection was carried out at engine speeds of 2000, 3000, 4000, 5000, and 6000 rpm, using three fuel mixtures: 10 % plastic pyrolysis fuel with 90 % RON 90, 20 % plastic pyrolysis fuel with 80 % 90 RON, and 30 % plastic pyrolysis fuel with 70 % RON 90. Each test was repeated three times, with the output power measured using a dynamometer and exhaust emissions (CO and HC levels) recorded using a gas analyzer. The test results show that the optimal fuel mixture to produce maximum engine power is a PE-RON 90 mixture with a ratio of 20:80, providing the best performance at medium to high engine speeds (3000–6000 rpm) with low CO emissions. The highest power output (1.05) occurs at 4000 rpm, while the PE-RON 90 30:70 alloy produces the best power performance at 6000 rpm (0.78 % CO). Additionally, the pyrolysis fuel blend significantly reduces CO and HC emissions, with the PE-RON 90 30:70 blend showing the lowest CO (0.78 % at 6000 rpm) and consistently reducing HC emissions across the rpm range

References

- Miandad, R., Rehan, M., Barakat, M. A., Aburiazaiza, A. S., Khan, H., Ismail, I. M. I. et al. (2019). Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based Biorefineries. Frontiers in Energy Research, 7. https://doi.org/10.3389/fenrg.2019.00027

- Budsaereechai, S., Hunt, A. J., Ngernyen, Y. (2019). Catalytic pyrolysis of plastic waste for the production of liquid fuels for engines. RSC Advances, 9 (10), 5844–5857. https://doi.org/10.1039/c8ra10058f

- Aziz, A. N., Al-Dadah, R., Kuznetsova, I., Mahmoud, S., Dhesi, S., Effiong, C., Kanu, E. (2021). Conversion of Mixed Waste of Wood and Plastic to Clean Fuels Using Pyrolysis in Nigeria – Numerical Study. Proceedings of the 7th World Congress on Mechanical, Chemical, and Material Engineering. https://doi.org/10.11159/htff21.135

- Olalo, J. (2021). Characterization of Pyrolytic Oil Produced from Waste Plastic in Quezon City, Philippines Using Non-catalytic Pyrolysis Method. Chemical Engineering Transactions, 86, 1495–1500. https://doi.org/10.3303/CET2186250

- Nafii, A., Irawan, B. (2024). Effect of ethanol and water fuel mixture in direct injection diesel engine on power and specific fuel consumption. Evrimata: Journal of Mechanical Engineering, 1 (2), 44–50. https://doi.org/10.70822/evrmata.vi.36

- Suhartono, S., Romli, A., Harsanti, M., Suharto, S., Achmad, F. (2022). Characteristics study of liquid fuel from pyrolysis of polyethylene plastic waste. Jurnal Teknologi, 84 (4), 57–64. https://doi.org/10.11113/jurnalteknologi.v84.17517

- Santoso, S., Yulianto, F. A., Yudiyanto, E., Aditya, C., Sabarudin, S. (2024). The Effect of Fuel Pump Pressure and Number of Injector Holes on 150cc Matic Motorcycle Performance. Asian Journal Science and Engineering, 2 (2), 117. https://doi.org/10.51278/ajse.v2i2.1020

- Aragaw, T. A., Mekonnen, B. A. (2021). Current plastics pollution threats due to COVID-19 and its possible mitigation techniques: a waste-to-energy conversion via Pyrolysis. Environmental Systems Research, 10 (1). https://doi.org/10.1186/s40068-020-00217-x

- Selvaranjan, K., Navaratnam, S., Rajeev, P., Ravintherakumaran, N. (2021). Environmental challenges induced by extensive use of face masks during COVID-19: A review and potential solutions. Environmental Challenges, 3, 100039. https://doi.org/10.1016/j.envc.2021.100039

- Al Aiti, M., Jehnichen, D., Fischer, D., Brünig, H., Heinrich, G. (2018). On the morphology and structure formation of carbon fibers from polymer precursor systems. Progress in Materials Science, 98, 477–551. https://doi.org/10.1016/j.pmatsci.2018.07.004

- Naufal Hana Rizqullah, Monasari, R., Utami Handayani, S., Aditya, C. (2024). Effect of mixing plastic pyrolysis oil with pertamax and variation of ignition timing on performance and emissions. Evrimata: Journal of Mechanical Engineering, 1 (1), 21–24. https://doi.org/10.70822/evrmata.vi.18

- Desnia, E., Rosie, E., Hartono, S. B., Simanullang, W. F., Anggorowati, A. A., Lourentius, S. (2024). Optimization of pyroliysis of polypropylene and polyethylene based plastic waste become an alternative oil fuel using bentonite catalyst. E3S Web of Conferences, 475, 05006. https://doi.org/10.1051/e3sconf/202447505006

- Mustapa, M. S. B., Setiawan, A., Gumono, G. (2023). The Effect of Active Carbon from Coconut Shell as an Adsorbent on Motorcycle Exhaust Gas Emissions and Engine Performance. Asian Journal Science and Engineering, 2 (1), 13–21. https://doi.org/10.51278/ajse.v2i1.675

- Kurniawan, S., Pebrianti, D. (2023). Optimization Study of the Ratio of Bioethanol Bioaceton Ron 90 on the Power and Emissions of a 110cc Gasoline Motor. Asian Journal Science and Engineering, 2 (1), 22. https://doi.org/10.51278/ajse.v2i1.759

- Al-Fatesh, A. S., AL-Garadi, N. Y. A., Osman, A. I., Al-Mubaddel, F. S., Ibrahim, A. A., Khan, W. U. et al. (2023). From plastic waste pyrolysis to Fuel: Impact of process parameters and material selection on hydrogen production. Fuel, 344, 128107. https://doi.org/10.1016/j.fuel.2023.128107

- Mottaa, I. L., Marchesanb, A. N., Guimarãesc, H. R., Chagasc, M. F., Bonomic, A., Macielb, M. R. W., Filho, R. M. (2024). Co-Pyrolysis of Lignocellulosic Residues and Plastics: a Simulation Approach to Predict Product Yields. Chemical Engineering Transactions, 109, 139–144. https://doi.org/10.3303/CET24109024

- Rizqiani, F., Irawan, B. (2024). Effect of a Mixture of Gasoline and Ethanol in a Direct Injection System Engine on Power and Specific Fuel Consumption. Evrimata: Journal of Mechanical Engineering, 1 (3), 63–68. https://doi.org/10.70822/evrmata.v1i03.34

- Stallkamp, C., Hennig, M., Volk, R., Stapf, D., Schultmann, F. (2024). Pyrolysis of mixed engineering plastics: Economic challenges for automotive plastic waste. Waste Management, 176, 105–116. https://doi.org/10.1016/j.wasman.2024.01.035

- Sánchez-Borrego, F. J., Álvarez-Mateos, P., García-Martín, J. F. (2021). Biodiesel and Other Value-Added Products from Bio-Oil Obtained from Agrifood Waste. Processes, 9 (5), 797. https://doi.org/10.3390/pr9050797

- Putra Gitama, N., Hidayat, N., Pebrianti, D. (2024). Effect of Coconut Shell-Based Active Carbon Adsorbent on Motorcycle Exhaust Gas Emissions. Evrimata: Journal of Mechanical Engineering, 1 (3), 88–96. https://doi.org/10.70822/evrmata.v1i03.57

- Majzoub, W. N., Al-Rawashdeh, M., Al-Mohannadi, D. M. (2024). Toward Building Circularity in Sustainable Plastic Waste Conversion. ACS Sustainable Chemistry & Engineering, 12 (23), 8642–8661. https://doi.org/10.1021/acssuschemeng.4c00383

- Hossain, S. T., Mahmud, M. A. P. (2024). Optimizing process parameters and materials for the conversion of plastic waste into hydrogen. Engineering Research Express, 6 (4), 045319. https://doi.org/10.1088/2631-8695/ad829f

- Yaqoob, H., Ali, H. M., Sajjad, U., Hamid, K. (2024). Investigating the potential of plastic pyrolysis oil-diesel blends in diesel engine: Performance, emissions, thermodynamics and sustainability analysis. Results in Engineering, 24, 103336. https://doi.org/10.1016/j.rineng.2024.103336

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Sugeng Hadi Susilo, Imam Mashudi, Santoso Santoso, Agus Hardjito, Dwi Pebrianti

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.