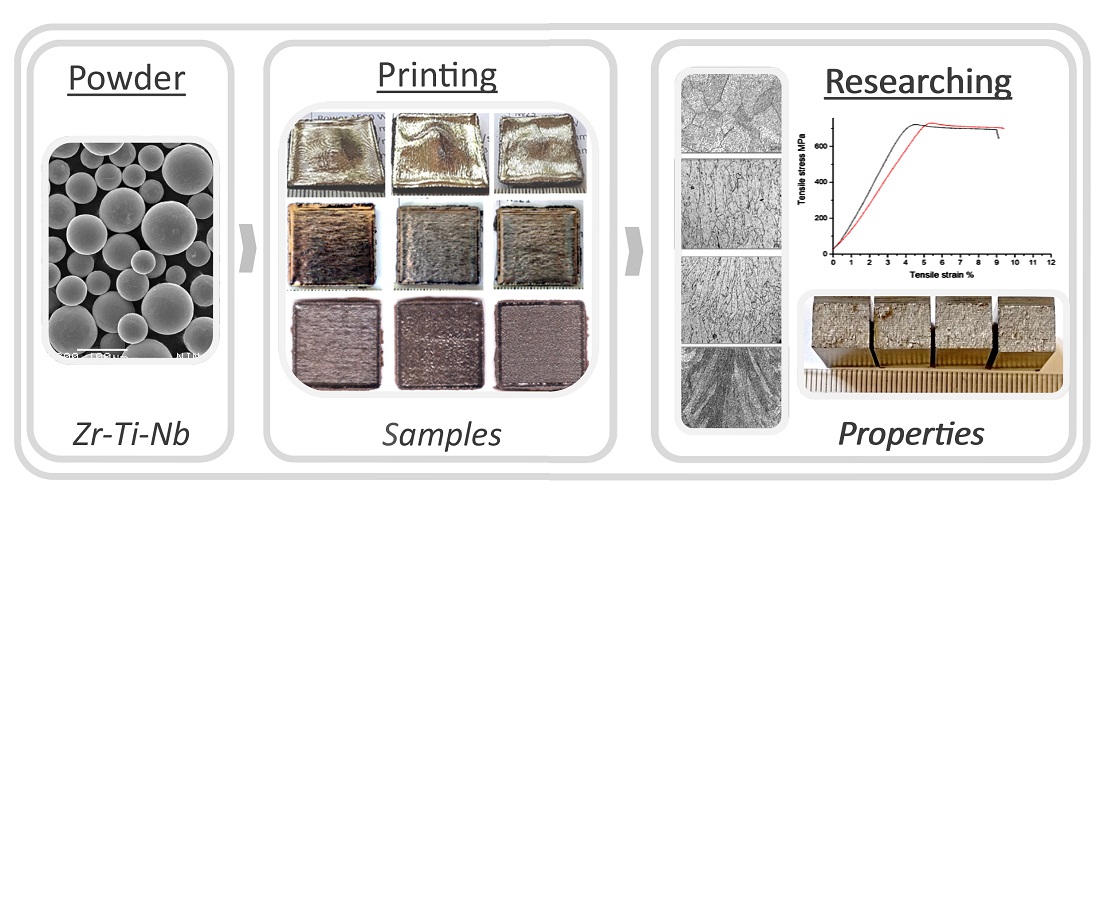

Determining technological parameters for the additive electron-beam surfacing of blanks for medical implants made of Zr-Ti-Nb alloy

DOI:

https://doi.org/10.15587/1729-4061.2025.322118Keywords:

additive technologies, electron beam, energy density, layer-by-layer surfacing, dental implant, low-modulus alloyAbstract

The object of this study is the alloys of the Zr-Ti-Nb system, which better than titanium alloys meet the criterion for mechano-biocompatibility of the material for dental implants. The choice of this material is due to the fact that zirconium alloys are free of toxic elements and have a low modulus of elasticity. Under modern conditions of active implementation of additive technologies for the manufacture of metal products, the use of zirconium alloys for 3D printing is a promising area. Such technologies include electron-beam growing of products. The task solved in this work relates to the lack of technological modes for electron beam technology, specifically for zirconium alloy. A rational regime has been determined, under which samples were grown from the alloy of the Zr-Ti-Nb system with a smooth surface, uniform structure, and no internal defects. It should be especially noted that the modulus of elasticity of the material of the manufactured samples was 59.8 GPa, which is two times lower than that of the titanium alloy Ti-6Al-4VELI (113.8 GPa) and is closer to the modulus of elasticity of human bone (30 GPa).

The results are explained from the point of view of physical-mechanical processes occurring in the metal during layer-by-layer surfacing under different conditions. These conditions were created by different values of technological parameters. Special feature of the results is that the formed requirements for the structure and properties of zirconium blanks were based on known dependences for titanium alloys. The findings showed that electron beam growing could become an alternative technology for manufacturing implant blanks from low-modulus zirconium alloy. The scope and conditions of practical use of the results extend to materials for implants in dentistry and, in the future, in orthopedics

References

- Fellah, M., Labaïz, M., Assala, O., Dekhil, L., Taleb, A., Rezag, H., Iost, A. (2014). Tribological behavior of Ti-6Al-4V and Ti-6Al-7Nb Alloys for Total Hip Prosthesis. Advances in Tribology, 2014, 1–13. https://doi.org/10.1155/2014/451387

- Elias, C. N., Lima, J. H. C., Valiev, R., Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60 (3), 46–49. https://doi.org/10.1007/s11837-008-0031-1

- Liang, S. X., Feng, X. J., Yin, L. X., Liu, X. Y., Ma, M. Z., Liu, R. P. (2016). Development of a new β Ti alloy with low modulus and favorable plasticity for implant material. Materials Science and Engineering: C, 61, 338–343. https://doi.org/10.1016/j.msec.2015.12.076

- Nune, K. C., Misra, R. D. K., Li, S. J., Hao, Y. L., Yang, R. (2017). Osteoblast cellular activity on low elastic modulus Ti–24Nb–4Zr–8Sn alloy. Dental Materials, 33 (2), 152–165. https://doi.org/10.1016/j.dental.2016.11.005

- Shi, L., Shi, L., Wang, L., Duan, Y., Lei, W., Wang, Z. et al. (2013). The Improved Biological Performance of a Novel Low Elastic Modulus Implant. PLoS ONE, 8 (2), e55015. https://doi.org/10.1371/journal.pone.0055015

- Mishchenko, O., Ovchynnykov, O., Kapustian, O., Pogorielov, M. (2020). New Zr-Ti-Nb Alloy for Medical Application: Development, Chemical and Mechanical Properties, and Biocompatibility. Materials, 13 (6), 1306. https://doi.org/10.3390/ma13061306

- Gnilitskyi, I., Pogorielov, M., Viter, R., Ferraria, A. M., Carapeto, A. P., Oleshko, O. et al. (2019). Cell and tissue response to nanotextured Ti6Al4V and Zr implants using high-speed femtosecond laser-induced periodic surface structures. Nanomedicine: Nanotechnology, Biology and Medicine, 21, 102036. https://doi.org/10.1016/j.nano.2019.102036

- Ivasishin, O. M., Skiba, I. A., Karasevskaya, O. P., Markovskiy, P. E., Shivanyuk, V. N., Kalashnikov, A. V. et al. (2014). Fizicheskie principy sozdaniya nizkomodul'nyh splavov na osnove cirkoniya i titana dlya izgotovleniya implantatov. Litopys travmatolohiyi ta ortopediyi, 1-2 (29-30), 261.

- Ivasyshyn, O. M., Skyba, I. O., Karasevska, O. P., Markovskyi, P. Ye. (2011). Pat. No. 102455 UA. Biocompatible alloy with low elasticity modulus containing zirconium and titanium (variants). No. а201115314; declareted: 26.12.2011; published: 10.07.2013, Bul. No. 13.

- Mishchenko, O., Solodovnyk, O., Deineka, V., Oleshko, O. (2020). Cellular response (osteoblasts and fibroblasts) depending on the type of surface of dental implants. Morphologia, 14 (1), 42–49. https://doi.org/10.26641/1997-9665.2020.1.42-49

- Frazier, W. E. (2014). Metal Additive Manufacturing: A Review. Journal of Materials Engineering and Performance, 23 (6), 1917–1928. https://doi.org/10.1007/s11665-014-0958-z

- Gasser, A., Backes, G., Kelbassa, I., Weisheit, A., Wissenbach, K. (2010). Laser Additive Manufacturing. Laser Technik Journal, 7 (2), 58–63. https://doi.org/10.1002/latj.201090029

- Azhazha, V. M., V'yugov, P. N., Lavrinenko, S. D., Lindt, K. A., Muhachev, A. P., Pipipenko, N. N. (1998). Cirkoniy i ego splavy: tekhnologi proizvodstva, oblast' primeneniya. Kharkiv: NN HFTI, 89.

- Ovchynnykov, O. V., Khaznaferov, M. V. (2022). Vstup do adytyvnykh tekhnolohiy kolorovykh metaliv. Kyiv: Naukova dumka, 122.

- Balachandramurthi, A. R., Moverare, J., Mahade, S., Pederson, R. (2018). Additive Manufacturing of Alloy 718 via Electron Beam Melting: Effect of Post-Treatment on the Microstructure and the Mechanical Properties. Materials, 12 (1), 68. https://doi.org/10.3390/ma12010068

- Juechter, V., Scharowsky, T., Singer, R. F., Körner, C. (2014). Processing window and evaporation phenomena for Ti–6Al–4V produced by selective electron beam melting. Acta Materialia, 76, 252–258. https://doi.org/10.1016/j.actamat.2014.05.037

- Ovchynnykov, O. V., Khaznaferov, M. V., Moisieiev, S. V., Mishchenko, O. M., Ovchynnykov, O. O. (2022). Pat. No. 128545 UA. A method for obtaining powder from spherical granules by plasma atomization of a workpiece and powder obtained by this method. No. a202200817; declareted: 22.02.2022; published: 08.08.2024, Bul. No. 34.

- Hrabe, N., Quinn, T. (2013). Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Materials Science and Engineering: A, 573, 271–277. https://doi.org/10.1016/j.msea.2013.02.065

- Matviichuk, V. A., Nesterenkov, V. M., Berdnikova, O. M. (2022). Additive electron beam technology of manufacture of metal products from powder materials. Automatic Welding, 2, 16–25. https://doi.org/10.37434/as2022.02.03

- Matviichuk, V. A., Nesterenkov, V. M. (2020). Additive electron beam equipment for layer-by-layer manufacture of metal products from powder materials. The Paton Welding Journal, 2020 (2), 41–46. https://doi.org/10.37434/tpwj2020.02.08

- Matviichuk, V., Nesterenkov, V., Berdnikova, O. (2022). Determining the influence of technological parameters of the electron-beam surfacing process on quality indicators. Eastern-European Journal of Enterprise Technologies, 1 (12 (115)), 21–30. https://doi.org/10.15587/1729-4061.2022.253473

- Matviichuk, V., Nesterenkov, V., Berdnikova, O. (2024). Determining the influence of technological parameters of electron beam surfacing process on the microstructure and microhardness of Ti-6Al-4V alloy. Eastern-European Journal of Enterprise Technologies, 1 (12 (127)), 6–12. https://doi.org/10.15587/1729-4061.2024.297773

- Grade 23 Ti 6Al 4V ELI Alloy (UNS R56401) (2013). AZOM. Available at: https://www.azom.com/article.aspx?ArticleID=9365

- Bezymyanniy, Yu. G., Kozirackiy, E. A., Nazarenko, V. A., Teslenko, L. O. (2017). Osobennosti akusticheskih izmereniy v pressovkah na osnove poroshka titana. Visnyk NTU «KhPI», 4 (1226), 3–7.

- Veretilnyk, O. V., Biktagirov, F. K. (2024). Electroslag processing of Kh18N10T stainless steel shavings. Electrometallurgy Today, 3, 31–35. https://doi.org/10.37434/sem2024.03.04

- Zhai, Y., Galarraga, H., Lados, D. A. (2016). Microstructure, static properties, and fatigue crack growth mechanisms in Ti-6Al-4V fabricated by additive manufacturing: LENS and EBM. Engineering Failure Analysis, 69, 3–14. https://doi.org/10.1016/j.engfailanal.2016.05.036

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Volodymyr Efanov, Vladyslav Matviichuk, Vladimir Nesterenkov, Olexandr Zavgorodny, Roman Bilyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.