Implementation of advanced vibration analysis techniques for predictive maintenance of rotating machinery

DOI:

https://doi.org/10.15587/1729-4061.2025.323894Keywords:

predictive maintenance, machine learning, vibration analysis, rotating machinery, bearing faultsAbstract

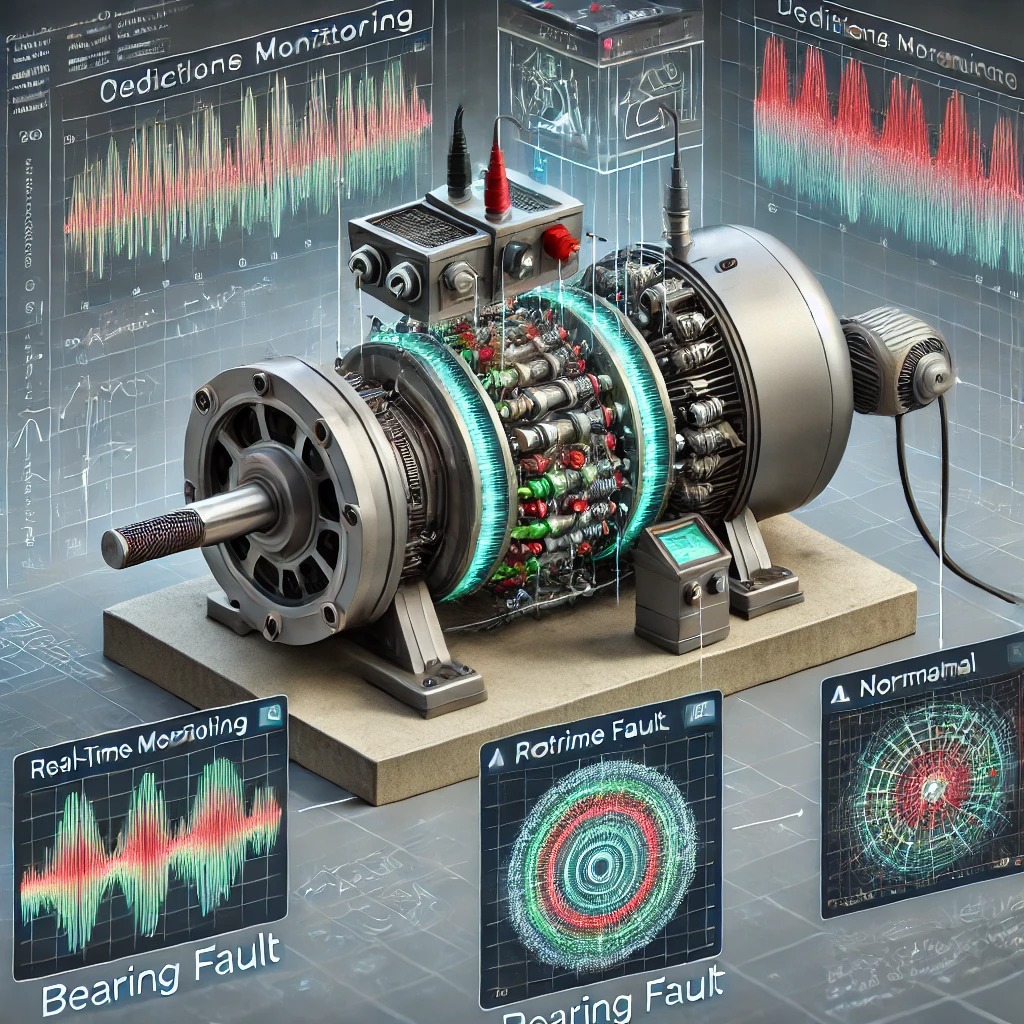

This study focuses on the predictive maintenance of rotating machinery – a fundamental asset in industries such as manufacturing, energy production, and transportation. The problem addressed is the frequent occurrence of undetected faults, such as bearing defects and shaft bending, which can lead to unexpected downtime and significant maintenance costs due to the limitations of traditional diagnostic methods in complex, noisy environments. To overcome these challenges, an integrated framework was developed that combines advanced vibration analysis techniques (including wavelet transforms and matching pursuit) with a suite of state-of-the-art machine learning models, including Random Forest, Support Vector Machine (SVM), Gradient Boosting, Convolutional Neural Network (CNN), and Long Short-Term Memory (LSTM). This innovative approach, characterized by robust feature extraction and data-driven modeling capabilities, achieves fault detection accuracies of up to 97 %, distinguishing it from conventional solutions. The findings demonstrate that the improved accuracy and reliability of the proposed framework effectively address long-standing issues related to incomplete fault detection and downtime in maintenance processes. By providing a scalable, noise-robust solution, the study contributes to industrial systems through significant reductions in operational overhead and downtime, thereby maintaining core business operations at peak performance

References

- Kumar, P., Hati, A. S. (2020). Review on Machine Learning Algorithm Based Fault Detection in Induction Motors. Archives of Computational Methods in Engineering, 28 (3), 1929–1940. https://doi.org/10.1007/s11831-020-09446-w

- Lei, Y., Jia, F., Lin, J., Xing, S., Ding, S. X. (2016). An Intelligent Fault Diagnosis Method Using Unsupervised Feature Learning Towards Mechanical Big Data. IEEE Transactions on Industrial Electronics, 63 (5), 3137–3147. https://doi.org/10.1109/tie.2016.2519325

- Shao, S.-Y., Sun, W.-J., Yan, R.-Q., Wang, P., Gao, R. X. (2017). A Deep Learning Approach for Fault Diagnosis of Induction Motors in Manufacturing. Chinese Journal of Mechanical Engineering, 30 (6), 1347–1356. https://doi.org/10.1007/s10033-017-0189-y

- Samiullah, M., Ali, H., Zahoor, S., Ali, A. (2024). Fault Diagnosis on Induction Motor using Machine Learning and Signal Processing. arXiv. https://doi.org/10.48550/arXiv.2401.15417

- Shao, H., Jiang, H., Zhang, X., Niu, M. (2015). Rolling bearing fault diagnosis using an optimization deep belief network. Measurement Science and Technology, 26 (11), 115002. https://doi.org/10.1088/0957-0233/26/11/115002

- Bahgat, B. H., Elhay, E. A., Elkholy, M. M. (2024). Advanced fault detection technique of three phase induction motor: comprehensive review. Discover Electronics, 1 (1). https://doi.org/10.1007/s44291-024-00012-3 3

- Gawde, S., Patil, S., Kumar, S., Kamat, P., Kotecha, K., Abraham, A. (2023). Multi-fault diagnosis of Industrial Rotating Machines using Data-driven approach: A review of two decades of research. Engineering Applications of Artificial Intelligence, 123, 106139. https://doi.org/10.1016/j.engappai.2023.106139

- Chevtchenko, S. F., Santos, Monalisa. C. M. dos, Vieira, Diego. M., Mota, Ricardo. L., Rocha, E., Cruz, Bruna. V. et al. (2023). Predictive Maintenance Model Based on Anomaly Detection in Induction Motors: A Machine Learning Approach Using Real-Time IoT Data. Proceeding of the 33rd European Safety and Reliability Conference, 3173–3180. https://doi.org/10.3850/978-981-18-8071-1_p578-cd

- Srinivasan, B., Srinivasan, R., Natarajan, B., Agarwal, D., Shashank, S., Anbalagan, S. (2025). Active Foundational Models for Fault Diagnosis of Electrical Motors. https://doi.org/10.2139/ssrn.5101043

- Hoang, D.-T., Kang, H.-J. (2019). Rolling element bearing fault diagnosis using convolutional neural network and vibration image. Cognitive Systems Research, 53, 42–50. https://doi.org/10.1016/j.cogsys.2018.03.002

- Qi, G., Zhu, Z., Erqinhu, K., Chen, Y., Chai, Y., Sun, J. (2018). Fault-diagnosis for reciprocating compressors using big data and machine learning. Simulation Modelling Practice and Theory, 80, 104–127. https://doi.org/10.1016/j.simpat.2017.10.005

- Tian, Y., Fu, M., Wu, F. (2015). Steel plates fault diagnosis on the basis of support vector machines. Neurocomputing, 151, 296–303. https://doi.org/10.1016/j.neucom.2014.09.036

- Santos, P., Villa, L., Reñones, A., Bustillo, A., Maudes, J. (2015). An SVM-Based Solution for Fault Detection in Wind Turbines. Sensors, 15 (3), 5627–5648. https://doi.org/10.3390/s150305627

- Wong, P. K., Yang, Z., Vong, C. M., Zhong, J. (2014). Real-time fault diagnosis for gas turbine generator systems using extreme learning machine. Neurocomputing, 128, 249–257. https://doi.org/10.1016/j.neucom.2013.03.059

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Gulsim Rysbayeva, Anara Umurzakova, Mohammed Alanesi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.