Establishing the rules of formation of fire-resistant biocomposites for building materials

DOI:

https://doi.org/10.15587/1729-4061.2025.326655Keywords:

biocomposites, fire resistance, intumescent coating, plant materials, adhesive ability, foam coke layerAbstract

The object of this study is the process of forming a heat-insulating layer of foam coke under thermal action on a biocomposite with the presence of an intumescent coating. The task addressed is to establish the effectiveness of the formation of a heat-insulating intumescent layer of foam coke under thermal action on an intumescent coating, which effectively inhibits high temperature. It has been proven that when wood and fabric are treated with fire retardants, chemical bonds arise that characterize symmetric and asymmetric valence vibrations of C–H in the methyl and methylene groups of lignin and cellulose. For wood treated with an intumescent coating, the value of the adhesive strength was set at 0.25 MPa, while the destruction occurred along the polymer shell with a detachment area of about 25 %. For particleboard treated with an intumescent coating, the value of the adhesion strength is about 0.45 MPa, while the failure occurred along the polymer shell with a separation area of about 10 %.

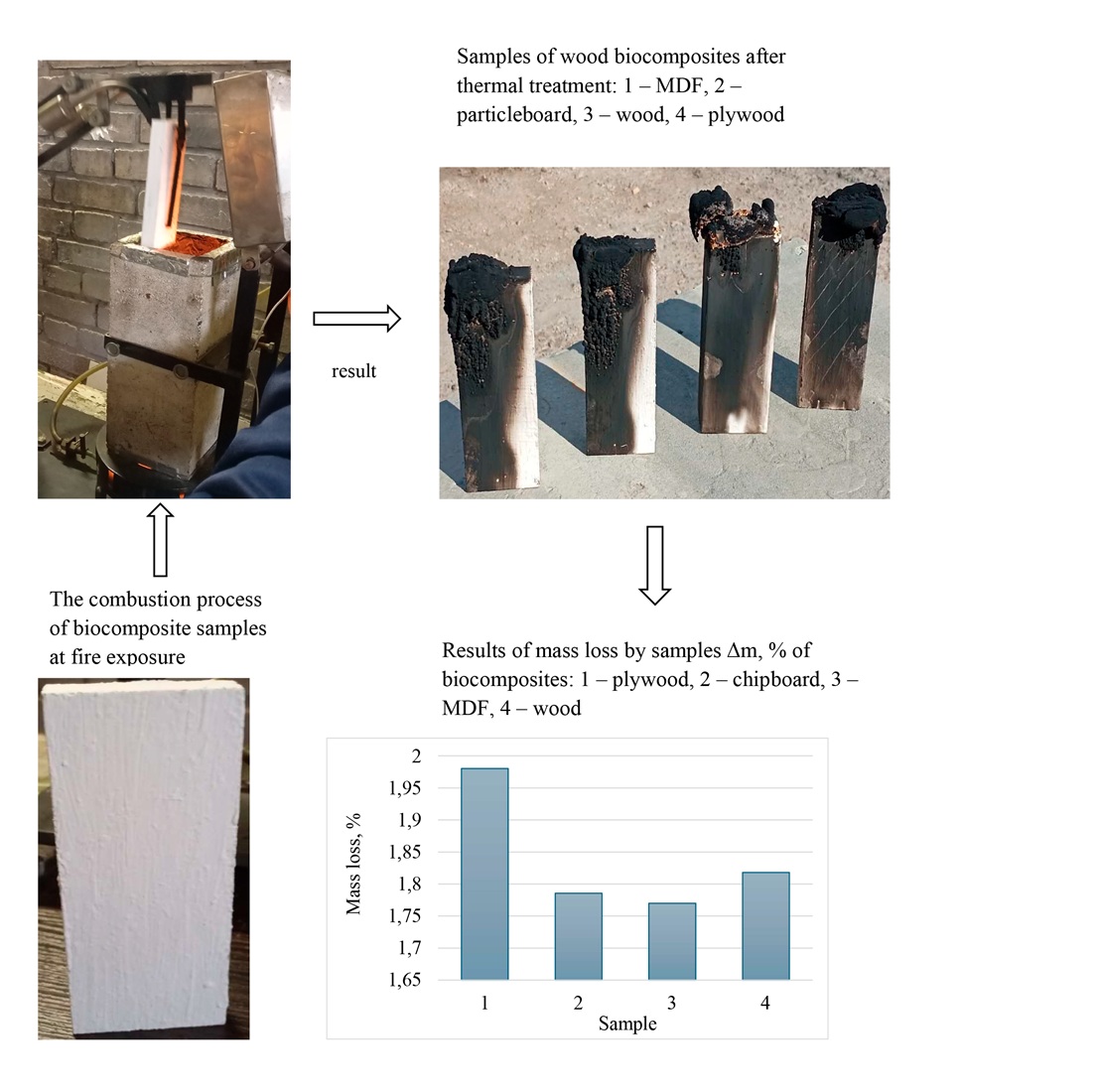

Based on the results, it was found that under the action of the burner flame, the temperature of the gaseous combustion products did not exceed 185 °C, and the mass loss was less than 2 %. During the thermal action of the coating, a layer of foam coke more than 20 mm thick was formed. Under the action of the burner flame on the biocomposite based on tarpaulin fabric, intensive swelling of the coating began, which led to the formation of a heat-insulating layer of foam coke more than 9 mm thick, ignition and flame spread did not occur.

Thus, the mechanism of fire protection by an intumescent coating is determined by decomposition under the influence of temperature with heat absorption and release of non-combustible gases; by inhibiting oxidation in the gas and condensed phases and by forming a heat-protective coke layer on the surface of the material.

The practical significance of the study is that the results related to determining the flame retardant properties of biocomposites could be taken into account when designing fire-resistant structures

References

- Hájková, K., Holeček, T., Filipi, M., Bárta, J., Sikora, A., Özkan, U. (2025). Production and properties of particleboard and paper from waste poppy straw. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-024-82733-9

- Agustiany, E. A., Nawawi, D. S., Fatriasari, W., Wahit, M. U., Vahabi, H., Kayla, D. S., Hua, L. S. (2025). Mechanical, morphological, thermal, and fire-retardant properties of sustainable chitosan-lignin based bioplastics. International Journal of Biological Macromolecules, 306, 141445. https://doi.org/10.1016/j.ijbiomac.2025.141445

- Li, W., Chen, M., Dai, Y., Ke, L.-L. (2025). Analysis on moisture-induced stresses in wood cell wall considering periodically graded microstructures. International Journal of Solids and Structures, 312, 113277. https://doi.org/10.1016/j.ijsolstr.2025.113277

- Kumar, N., Rawat, P., Kandasami, R. K. (2025). Enhancing the characteristics of natural coir fiber yarns using biopolymer for textile reinforced cementitious composites. Construction and Building Materials, 470, 140427. https://doi.org/10.1016/j.conbuildmat.2025.140427

- Bhuiyan, M. A. R., Bari, M. A., Darda, M. A. (2025). Thermal barrier performance of natural fiber-reinforced biocomposite panels with the reflective surface for conserving heat energy in buildings. Energy Conversion and Management: X, 26, 100926. https://doi.org/10.1016/j.ecmx.2025.100926

- Pantaleoni, A., Marrocchi, A., Russo, P., Malucelli, G., Altamura, D., Nardelli, F. et al. (2025). Advanced flame-retardant biocomposites: Polylactic acid reinforced with green gallic acid‑iron‑phosphorus coated flax fibers. International Journal of Biological Macromolecules, 300, 140215. https://doi.org/10.1016/j.ijbiomac.2025.140215

- Miao, B. H., Woo, D., Javan, D., Garboczi, E. J., Headrick, R. J., Lesh, A. C. et al. (2025). Recycling of lignin-based biocomposites: Improving sustainability and enhancing material strength. Resources, Conservation and Recycling, 215, 108104. https://doi.org/10.1016/j.resconrec.2024.108104

- Olanrewaju, O., Oladele, I. O., Adelani, S. O. (2025). Recent advances in natural fiber reinforced metal/ceramic/polymer composites: An overview of the structure-property relationship for engineering applications. Hybrid Advances, 8, 100378. https://doi.org/10.1016/j.hybadv.2025.100378

- Winandy, J. E., Morrell, J. J. (2017). Improving the utility, performance, and durability of wood- and bio-based composites. Annals of Forest Science, 74 (1). https://doi.org/10.1007/s13595-017-0625-2

- Das, O., Kim, N. K., Hedenqvist, M. S., Bhattacharyya, D. (2019). The flammability of biocomposites. Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 335–365. https://doi.org/10.1016/b978-0-08-102290-0.00015-5

- Madyaratri, E., Ridho, M., Aristri, M., Lubis, M., Iswanto, A., Nawawi, D. et al. (2022). Recent Advances in the Development of Fire-Resistant Biocomposites – A Review. Polymers, 14 (3), 362. https://doi.org/10.3390/polym14030362

- Feng, J., Lu, Y., Xie, H., Zhang, Y., Huo, S., Liu, X. et al. (2023). Atom-economic synthesis of an oligomeric P/N-containing fire retardant towards fire-retarding and mechanically robust polylactide biocomposites. Journal of Materials Science & Technology, 160, 86–95. https://doi.org/10.1016/j.jmst.2023.04.003

- Pettersen, R. C. (1984). The Chemical Composition of Wood. The Chemistry of Solid Wood, 57–126. https://doi.org/10.1021/ba-1984-0207.ch002

- Tsapko, Y., Likhnyovskyi, R., Buiskykh, N., Horbachova, O., Mazurchuk, S., Lastivka, O. et al. (2023). Determining patterns in the formation of a polymer shell by powder paint on wood surface. Eastern-European Journal of Enterprise Technologies, 1 (10 (121)), 37–45. https://doi.org/10.15587/1729-4061.2023.273364

- Tsapko, Y., Tkachenko, T., Tsapko, А., Likhnyovskyi, R., Sukhanevych, M., Bereznutska, Y. et al. (2024). Defining patterns in the fire protection of wood with reactive coating. Eastern-European Journal of Enterprise Technologies, 6 (10 (132)), 55–63. https://doi.org/10.15587/1729-4061.2024.317334

- Tsapko, Y., Tsapko, A., Zhartovskyi, S., Likhnyovskyi, R., Kravchenko, M., Lialina, N. et al. (2024). Establishing fire protection patterns in wood using impregnation compositions from inorganic salts. Eastern-European Journal of Enterprise Technologies, 5 (10 (131)), 62–70. https://doi.org/10.15587/1729-4061.2024.313423

- Tsapko, Y., Tsapko, А., Likhnyovskyi, R., Sukhanevych, M., Zapolskiy, L., Illiuchenko, P., Bedratiuk, O. (2024). Establishing patterns in reducing fire-dangerous properties of sip panels fire-protected with reactive coating. Eastern-European Journal of Enterprise Technologies, 1 (10 (127)), 47–54. https://doi.org/10.15587/1729-4061.2024.298266

- Tsapko, Y., Tsapko, А., Prisyazhnuk, V., Klymas, R., Likhnyovskyi, R., Slutskaya, O. et al. (2024). Revealing patterns in reducing the fire-hazardous properties of insulation made from plant raw materials. Ecology, 4 (10 (130)), 29–37. https://doi.org/10.15587/1729-4061.2024.309705

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yuriy Tsapko, Аleksii Tsapko, Ruslan Likhnyovskyi, Kostiantyn Shumbar, Oksana Slutska, Oksana Berdnyk, Anna Borysova, Oleksandr Dotsenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.