Development of an electric milk pasteurizer for farming

DOI:

https://doi.org/10.15587/1729-4061.2025.327666Keywords:

animal husbandry, pasteurization, electric pasteurization, induction heater, bactericidal cycle, induction energyAbstract

The object of study is the milk pasteurization by way of improving construction parameters. Main target experimental substantiation of the design and technological parameters of an improved heater based on the use of an induction heater and conducting production tests of an experimental pasteurizer, evaluating its performance and quality indicators. This study is in the nature of a search for a method to preserve the milk quality.

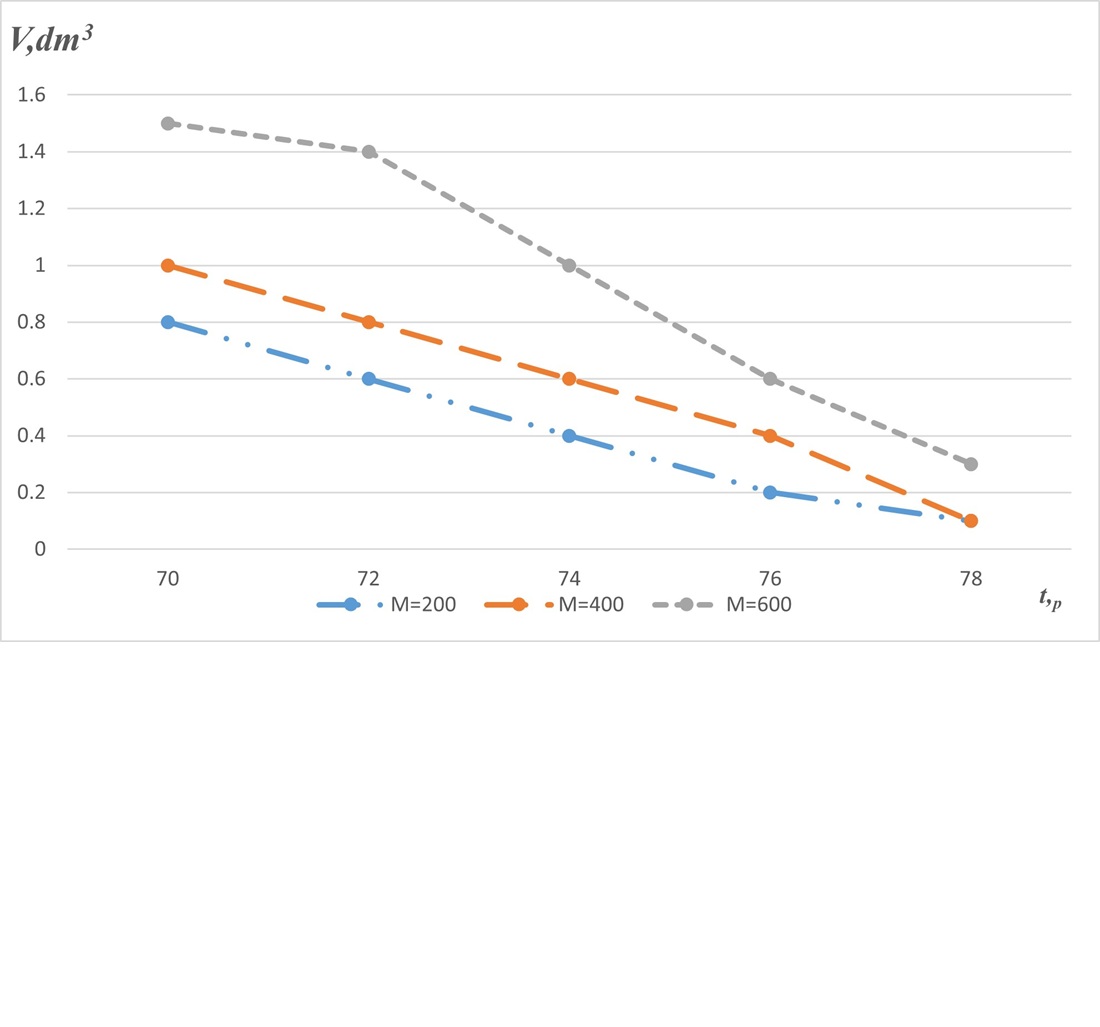

The study consists of the direction of improving the flow-through and parallel-cumulative induction pasteurizer, the design of the continuous-acting induction milk pasteurizer, the substantiated mathematical dependences of the interrelationships of its effective design and operating parameters, as well as the method of technical parameter reporting and evaluation of the effect of the improved experimental pasteurizer on the basic milk properties.

The bactericidal phase before and after milk pasteurization in an experimental heater is as follows: for fresh milk (t=300 °C), the duration of the bactericidal phase is 2 hours, with self-cooling of fresh milk from 370 °C to 200 °C, the duration of the bactericidal phase is 3 hours, and when cooling milk to 8...100 °C – 8 hours. For pasteurized milk (t=300 °C), the duration of the bactericidal phase is 17 hours, and when the milk is cooled to 8–100 °C, the duration of the bactericidal phase is 30 hours. The proposed induction pasteurizer ensures efficient milk pasteurization produced on dairy farms, ensuring the possibility of direct delivery of the product to a retail chain or delivery to a processing plant without damage, which provides economic benefits to the farm.

The proposed induction pasteurization unit is recommended for use not only in small and medium-sized farms, but also in centralized district milk collection points

References

- Alsaedi, A. W. M., Al-Mousawi, A. J., Al-Hilphy, A. R., Gavahian, M. (2023). Non-thermal pasteurization of milk by an innovative energy-saving moderate electrical field equipped with elongated electrodes and process optimization. Innovative Food Science & Emerging Technologies, 88, 103445. https://doi.org/10.1016/j.ifset.2023.103445

- Al-Hilphy, A. R., Abdulstar, A. R., Gavahian, M. (2021). Moderate electric field pasteurization of milk in a continuous flow unit: Effects of process parameters, energy consumption, and shelf-life determination. Innovative Food Science & Emerging Technologies, 67, 102568. https://doi.org/10.1016/j.ifset.2020.102568

- Sur, A., Sah, R. P., Pandya, S. (2020). Milk storage system for remote areas using solar thermal energy and adsorption cooling. Materials Today: Proceedings, 28, 1764–1770. https://doi.org/10.1016/j.matpr.2020.05.170

- Barba, F. J., Gavahian, M., Es, I., Zhu, Z., Chemat, F., Lorenzo, J. M., Mousavi Khaneghah, A. (2019). Solar radiation as a prospective energy source for green and economic processes in the food industry: From waste biomass valorization to dehydration, cooking, and baking. Journal of Cleaner Production, 220, 1121–1130. https://doi.org/10.1016/j.jclepro.2019.02.175

- Beath, A., Meybodi, M. A., Drewer, G. (2022). Techno-economic assessment of application of particle-based concentrated solar thermal systems in Australian industry. Journal of Renewable and Sustainable Energy, 14 (3). https://doi.org/10.1063/5.0086655

- Lindsay, D., Robertson, R., Fraser, R., Engstrom, S., Jordan, K. (2021). Heat induced inactivation of microorganisms in milk and dairy products. International Dairy Journal, 121, 105096. https://doi.org/10.1016/j.idairyj.2021.105096

- Ayou, D. S., Hargiyanto, R., Coronas, A. (2022). Ammonia-based compression heat pumps for simultaneous heating and cooling applications in milk pasteurization processes: Performance evaluation. Applied Thermal Engineering, 217, 119168. https://doi.org/10.1016/j.applthermaleng.2022.119168

- Gritsenko, D. G., Chernyakov, M. K., Chernyakova, M. M., Chernyakova, I. A. (2019). Principles of state regulation of information in the dairy industry. Food industry, 11, 45–49.

- Galkin, D. G. (2018). Innovative development of ecologically pure food production: potential of technological platforms. Herald of the Belgorod University of Cooperation, Economics and Law, 2 (69), 87–96. https://doi.org/10.21295/2223-5639-2018-2-87-96

- Singh, G., Tyagi, V. V., Singh, P. J., Pandey, A. K. (2020). Estimation of thermodynamic characteristics for comprehensive dairy food processing plant: An energetic and exergetic approach. Energy, 194, 116799. https://doi.org/10.1016/j.energy.2019.116799

- Taghiyev, U., Yusubova, U. (2024). Conservation Techniques in Agriculture Under Climate Change. Agriculture and Water Management Under Climate Change, 173–192. https://doi.org/10.1007/978-3-031-74307-8_9

- Mok, J. H., Pyatkovskyy, T., Yousef, A., Sastry, S. K. (2019). Combined effect of shear stress and moderate electric field on the inactivation of Escherichia coli K12 in apple juice. Journal of Food Engineering, 262, 121–130. https://doi.org/10.1016/j.jfoodeng.2019.05.019

- Khan, K. S., Latif, Y., Munir, A., Hensel, O. (2022). Comparative thermal analyses of solar milk pasteurizers integrated with solar concentrator and evacuated tube collector. Energy Reports, 8, 7917–7930. https://doi.org/10.1016/j.egyr.2022.06.001

- Nunes, L., Tavares, G. M. (2019). Thermal treatments and emerging technologies: Impacts on the structure and techno-functional properties of milk proteins. Trends in Food Science & Technology, 90, 88–99. https://doi.org/10.1016/j.tifs.2019.06.004

- Leeuwis, C. (2000). Reconceptualizing Participation for Sustainable Rural Development: Towards a Negotiation Approach. Development and Change, 31 (5), 931–959. https://doi.org/10.1111/1467-7660.00184

- Yerlikaya, O., Kynyk, O. (2019). Consumption of raw and thermally processed drinking milk from the point of view of food safety and human health. Journal of Food and Feed Science and Technology, 22, 8–10.

- Riling, C., Kamadurai, H., Kumar, S., O’Leary, C. E., Wu, K.-P., Manion, E. E. et al. (2015). Itch WW Domains Inhibit Its E3 Ubiquitin Ligase Activity by Blocking E2-E3 Ligase Trans-thiolation. Journal of Biological Chemistry, 290 (39), 23875–23887. https://doi.org/10.1074/jbc.m115.649269

- Hajiyev, R., Saidov, R., Mammadov, G., Taghiyev, U., Allahverdiyeva, G. (2022). Analysis of the main design and operating parameters of the device for the fermentation of bird droppings. EUREKA: Physics and Engineering, 5, 107–122. https://doi.org/10.21303/2461-4262.2022.002306

- Hajiyev, R. M., Salmanova, K., Mammadov, G., Taghiyev, U. (2022). Application of intensive technologies for improved production processes in poultry farms. Eastern-European Journal of Enterprise Technologies, 4 (1 (118)), 90–102. https://doi.org/10.15587/1729-4061.2022.262999

- Hajiyev, R. M., Saidov, R., Mammadov, G., Allahverdiyeva, G., Taghiyev, U. (2022). Utilization of poultry droppings in terms of non-waste technology. Eastern-European Journal of Enterprise Technologies, 3 (10 (117)), 37–46. https://doi.org/10.15587/1729-4061.2022.258493

- Hajiyev, R., Huseynova, M., Taghiyev, U., Mammadov, G., Allahverdiyeva, G. (2024). The study of the efficiency evaluation of the ventilation system of the poultry house in the summer. EUREKA: Physics and Engineering, 1, 82–92. https://doi.org/10.21303/2461-4262.2024.003248

- Saad, A. M., Vishnupriyan, S., Saleem, M., Khaldi, A., Khamis, A., Saidi, A. (2019). Design and development of solar milk pasteurizer. Conference: CAS Annual Symposium - The Fourth Industrial Revolution Symposium (FIR2019): Applications and Practices in Applied and Social Sciences. Available at: https://www.researchgate.net/publication/351355480_Design_and_Development_of_Solar_Milk_Pasteurizer

- Seyidov, Z. M., Mammadov, G. B. (2022). Optimization of installations for electrothermal processing of milk. Agrarian Science, 5, 128–131. https://doi.org/10.32634/0869-8155-2022-359-5-128-131

- Taran, E. N. (2011). Control of milk fat content in the automatic monitoring system of a dairy farm. Zelenograd, 24.

- The Law of the Republic of Azerbaijan "On Food Products" (2000). Baku: Publishing House "Bulletin of Business People", 15.

- Tasmin, N., Farjana, S. H., Hossain, M. R., Golder, S., Mahmud, M. A. P. (2022). Integration of Solar Process Heat in Industries: A Review. Clean Technologies, 4 (1), 97–131. https://doi.org/10.3390/cleantechnol4010008

- Makarova, G. V., Soloviev, S. V., Shilin, V. A. (2014). Pat. No. 137709U1 RU. Induction liquid heater with a soaking device.

- Verma, S. K., Gupta, N. K., Rakshit, D. (2020). A comprehensive analysis on advances in application of solar collectors considering design, process and working fluid parameters for solar to thermal conversion. Solar Energy, 208, 1114–1150. https://doi.org/10.1016/j.solener.2020.08.042

- Wingert, R., O’Hern, H., Orosz, M., Harikumar, P., Roberts, K., Otanicar, T. (2020). Spectral beam splitting retrofit for hybrid PV/T using existing parabolic trough power plants for enhanced power output. Solar Energy, 202, 1–9. https://doi.org/10.1016/j.solener.2020.03.066

- Yılmaz, İ. H., Mwesigye, A., Göksu, T. T. (2020). Enhancing the overall thermal performance of a large aperture parabolic trough solar collector using wire coil inserts. Sustainable Energy Technologies and Assessments, 39, 100696. https://doi.org/10.1016/j.seta.2020.100696

- Liu, Y., Xiong, L., Kontopodi, E., Boeren, S., Zhang, L., Zhou, P., Hettinga, K. (2020). Changes in the milk serum proteome after thermal and non-thermal treatment. Innovative Food Science & Emerging Technologies, 66, 102544. https://doi.org/10.1016/j.ifset.2020.102544

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Gabil Mammadov, Zohrab Seyidov, Rasim Saidov, Rovshan Hajiyev, Mehriban Huseynova, Urfan Taghiyev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.