Developing an efficient and economically viable method for pine nut processing

DOI:

https://doi.org/10.15587/1729-4061.2025.328828Keywords:

pine nut, shell, efficient device, rheological and mechanical properties, strength calculationAbstract

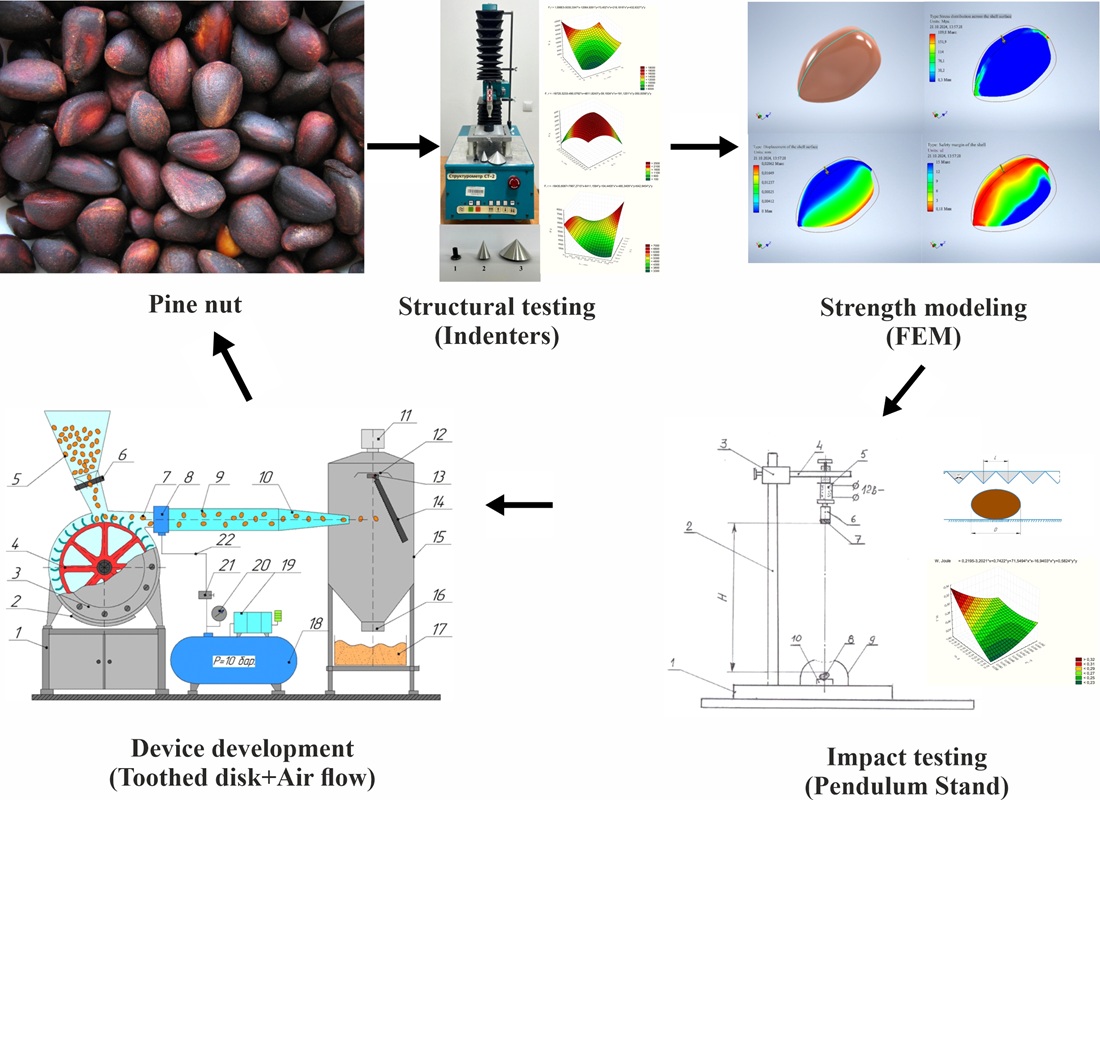

This study examines the strength characteristics of pine nut shells to enhance kernel extraction efficiency. Current methods have drawbacks, including high kernel damage, preheating, and excessive energy use. Laboratory tests using the ST-2 structural meter analyzed the shell's mechanical and rheological properties under varying moisture conditions.

The most effective shell-breaking method without kernel damage (for nuts 10.8–11.4 mm in diameter) involves a 90° cone indenter at a shell moisture level of 16–17 %, with an average breaking force of 7.0 kg. Mathematical modeling determined that under an impact force of 49 N and deformation of 1.1–1.3 mm, the required fracture energy is 0.245 J. Finite element analysis in Inventor software confirmed a pre-fracture displacement of 0.016 mm, with stress uniformly distributed across the shell.

A pendulum-based test rig studied shell fracture under impact loads. The optimal cracking mode was achieved with an impact mass of 40–60 g at a velocity of 35–40 m/s. A grooved impact surface (90°) with an L/D ratio of 0.4–0.6 reduced fracture energy by 10–15 %.

Pre-acceleration in an air stream before impact caused the least kernel damage, but low aerodynamic resistance limited efficiency. To address this, a new device was developed, combining a rotating toothed disk for initial acceleration with a compressed air stream to achieve an optimal velocity of 35–40 m/s. This approach increased whole kernel yield by 15–20 %, reduced energy consumption by 10 %, and minimized product damage.

The proposed method improves pine nut processing by increasing efficiency, reducing waste, and lowering costs. It is applicable in food and pharmaceutical industries for optimized kernel extraction while preserving product integrity

References

- Cárcel, L. M., Bon, J., Acuña, L., Nevares, I., del Álamo, M., Crespo, R. (2012). Moisture dependence on mechanical properties of pine nuts from Pinus pinea L. Journal of Food Engineering, 110 (2), 294–297. https://doi.org/10.1016/j.jfoodeng.2011.04.018

- Li, L., Man, X., Zhang, H., Lan, H., Tang, Y., Fan, X., Zhang, Y. (2023). Determination of Critical Moisture Content Facing Walnut Shell Breaking and Optimization of Combined Hot Air and Microwave Vacuum Drying Process. Applied Sciences, 13 (24), 13287. https://doi.org/10.3390/app132413287

- Han, B., Su, G., Zeng, Y., Yang, J., Fan, X., Zhang, Y. et al. (2023). FDEM investigation on the crack propagation characteristics of walnut shell under multi-contact loadings. Frontiers in Materials, 10. https://doi.org/10.3389/fmats.2023.1293683

- Nevzorov, V. N., Kokh, Zh. A., Golubev, I. V. (2023). Technology and equipment for extraction pine nut kernels. Conifers of the boreal area, XLI (6), 536–540.

- Lisowski, A., Pajor, M., Świętochowski, A., Dąbrowska, M., Klonowski, J., Mieszkalski, L. et al. (2019). Effects of moisture content, temperature, and die thickness on the compaction process, and the density and strength of walnut shell pellets. Renewable Energy, 141, 770–781. https://doi.org/10.1016/j.renene.2019.04.050

- Queirós, C. S. G. P., Cardoso, S., Lourenço, A., Ferreira, J., Miranda, I., Lourenço, M. J. V., Pereira, H. (2019). Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Conversion and Biorefinery, 10 (1), 175–188. https://doi.org/10.1007/s13399-019-00424-2

- Vursavuş, K., Özgüven, F. (2005). Fracture Resistance of Pine Nut to Compressive Loading. Biosystems Engineering, 90 (2), 185–191. https://doi.org/10.1016/j.biosystemseng.2004.11.004

- Man, X., Li, L., Zeng, Y., Tang, Y., Yang, J., Fan, X. et al. (2023). Mechanical impact characteristics of hollow shell granule based on continuous damage theory. Powder Technology, 429, 118946. https://doi.org/10.1016/j.powtec.2023.118946

- Özgüven, F., Vursavuş, K. (2005). Some physical, mechanical and aerodynamic properties of pine (Pinus pinea) nuts. Journal of Food Engineering, 68 (2), 191–196. https://doi.org/10.1016/j.jfoodeng.2004.05.031

- Abdoh, D. A. (2024). Three-dimensional modeling of impact fractures in brittle materials via peridynamics. Engineering Fracture Mechanics, 297, 109884. https://doi.org/10.1016/j.engfracmech.2024.109884

- Hamitbek, A. H., Kairbaeva, A. E. (2024). Experimental studies for the Development of special equipment for cleaning cedar nuts from the shell. Kompleksnoe Ispolzovanie Mineralnogo Syra = Complex Use of Mineral Resources, 333 (2), 34–40. https://doi.org/10.31643/2025/6445.15

- Huang, B., Liu, J., Jiao, J., Lu, J., Lv, D., Mao, J. et al. (2022). Applications of machine learning in pine nuts classification. Scientific Reports, 12 (1). https://doi.org/10.1038/s41598-022-12754-9

- Li, L., Mao, B., Zeng, Y., Tang, Y., Man, X., Fan, X. et al. (2023). Experimental study on crack irregularity of hollow shell particle under impact loading. Powder Technology, 427, 118704. https://doi.org/10.1016/j.powtec.2023.118704

- Zhang, H., Liu, H., Zeng, Y., Tang, Y., Zhang, Z., Che, J. (2022). Design and Performance Evaluation of a Multi-Point Extrusion Walnut Cracking Device. Agriculture, 12 (9), 1494. https://doi.org/10.3390/agriculture12091494

- Man, X., Li, L., Zhang, H., Lan, H., Fan, X., Tang, Y., Zhang, Y. (2023). Study on the Relationship between Crack Initiation and Crack Bifurcation in Walnut Shells Based on Energy. Agriculture, 14 (1), 69. https://doi.org/10.3390/agriculture14010069

- Nevzorov, V. N., Koch, Zh. A., Matskevich, I. V., Golubev, I. V. (2022) development of equipment for calibration and sorting of pine nuts. Conifers of the boreal area, XL (5), 439–443.

- Khamitbek, A. Kh., Kairbayeva, A. Y., Butabayev, M. Kh. (2024). Pat. No. 9833 KZ. A Device for Breaking the Shell of a Cedar Nut.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Ayat Khamitbek, Mir Butabayev, Ainura Kairbayeva, Sarsembek Oralbayev, Galymzhan Nasrullin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.