Devising a technology and optimizing processing parameters for making functional boiled sausage fortified with protein hydrolysates

DOI:

https://doi.org/10.15587/1729-4061.2025.330002Keywords:

protein hydrolysate, collagen, Box-Benkin design, optimization, amino nitrogen, water-holding capacityAbstract

The object of this study is the production of cooked sausages fortified with protein hydrolysates obtained from collagen-containing raw materials (in particular, beef legs with fetlock).

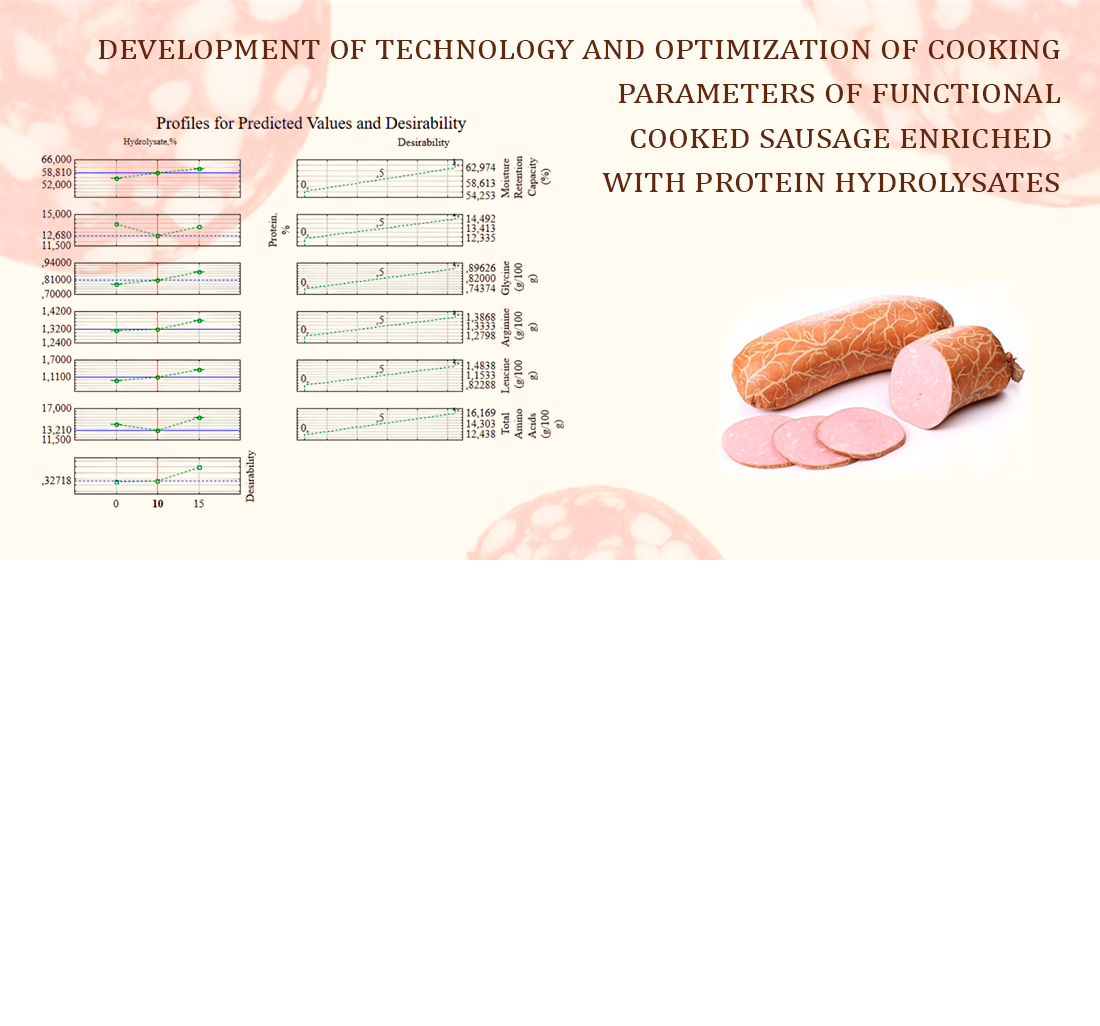

The study is aimed at eliminating the lack of data on the effect of hydrolysate concentration and process parameters on the functional, physicochemical, and antioxidant characteristics of meat products. A multifactorial experiment was conducted according to the Box-Benkin design in order to optimize the conditions of enzymatic hydrolysis. A statistically significant second-order regression model was built (R2=0.83; F=13.18; p<0.05). Response surface analysis made it possible to determine the optimal conditions: temperature treatment at 70.4 °C, fermentation at 50 °C, and a duration of 2 hours, at which the content of amino nitrogen reaches 2.00 mg/g.

In a single-factorial experiment, the effect of hydrolysate doses (0%, 10%, 15%) was studied. A strong linear relationship was found between the dose and water retention capacity (R2=0.98), with an increase of 9.3%. Antioxidant activity also increased (DPPH up to 29.88%, FRAP up to 33.5 mg GAE/g). The amino acid profile was improved by increasing the levels of leucine, glycine, and arginine. However, at the 15 % dose, a deterioration in organoleptic properties (taste and aroma) was observed, which reduced consumer acceptability.

The results confirm the effectiveness of combining mathematical modeling and biochemical analysis in the development of functional meat products based on collagen-containing by-products. Limitations of the hydrolysate application have been identified and directions for future research have been proposed: sensory validation, peptide fractionation, and testing of intermediate concentrations (12–14%) to achieve an optimal balance between functionality, quality, and taste

References

- González-Osuna, M. F., Bernal-Mercado, A. T., Wong-Corral, F. J., Ezquerra-Brauer, J. M., Soto-Valdez, H., Castillo, A. et al. (2024). Bioactive Peptides and Protein Hydrolysates Used in Meat and Meat Products’ Preservation – A Review. ACS Food Science & Technology, 4 (5), 1003–1016. https://doi.org/10.1021/acsfoodscitech.3c00605

- Mazorra-Manzano, M. A., Ramírez-Suarez, J. C., Yada, R. Y. (2017). Plant proteases for bioactive peptides release: A review. Critical Reviews in Food Science and Nutrition, 58 (13), 2147–2163. https://doi.org/10.1080/10408398.2017.1308312

- Mora, L., Toldrá, F. (2023). Advanced enzymatic hydrolysis of food proteins for the production of bioactive peptides. Current Opinion in Food Science, 49, 100973. https://doi.org/10.1016/j.cofs.2022.100973

- Wu, Y.-H. S., Chen, Y.-C. (2022). Trends and applications of food protein-origin hydrolysates and bioactive peptides. Journal of Food and Drug Analysis, 30 (2), 172–184. https://doi.org/10.38212/2224-6614.3408

- Sarker, A. (2022). A review on the application of bioactive peptides as preservatives and functional ingredients in food model systems. Journal of Food Processing and Preservation, 46 (8). https://doi.org/10.1111/jfpp.16800

- Daroit, D. J., Brandelli, A. (2021). In vivo bioactivities of food protein-derived peptides – a current review. Current Opinion in Food Science, 39, 120–129. https://doi.org/10.1016/j.cofs.2021.01.002

- López‐Barrios, L., Gutiérrez‐Uribe, J. A., Serna‐Saldívar, S. O. (2014). Bioactive Peptides and Hydrolysates from Pulses and Their Potential Use as Functional Ingredients. Journal of Food Science, 79 (3). https://doi.org/10.1111/1750-3841.12365

- Peighambardoust, S. H., Karami, Z., Pateiro, M., Lorenzo, J. M. (2021). A Review on Health-Promoting, Biological, and Functional Aspects of Bioactive Peptides in Food Applications. Biomolecules, 11 (5), 631. https://doi.org/10.3390/biom11050631

- Tayeva, A., Kozhakhiyeva, M., Jetpisbayeva, B., Tlevlessova, D., Samadun, A., Valiyv, A. (2023). Development of technology of boiled sausage from non-traditional raw materials. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 15–23. https://doi.org/10.15587/1729-4061.2023.277494

- Chen, M., Ma, A., Sun, Z., Xie, B., Shi, L., Chen, S. et al. (2023). Enhancing activity of food protein‐derived peptides: An overview of pretreatment, preparation, and modification methods. Comprehensive Reviews in Food Science and Food Safety, 22 (6), 4698–4733. https://doi.org/10.1111/1541-4337.13238

- Gedif, H., Tkaczewska, J. (2024). Sourcing, Use of Biopeptides, and Active Protein Hydrolysates as a Positive Response to Green Politics in the World – Current State and Challenges: A Review. Food and Bioprocess Technology, 17 (12), 4450–4472. https://doi.org/10.1007/s11947-024-03382-4

- Dey, P., Kadharbasha, S., Bajaj, M., Das, J., Chakraborty, T., Bhat, C., Banerjee, P. (2021). Contribution of Quasifibrillar Properties of Collagen Hydrolysates Towards Lowering of Interface Tension in Emulsion-Based Food Leading to Shelf-Life Enhancement. Food and Bioprocess Technology, 14 (8), 1566–1586. https://doi.org/10.1007/s11947-021-02640-z

- Cruz-Casas, D. E., Aguilar, C. N., Ascacio-Valdés, J. A., Rodríguez-Herrera, R., Chávez-González, M. L., Flores-Gallegos, A. C. (2021). Enzymatic hydrolysis and microbial fermentation: The most favorable biotechnological methods for the release of bioactive peptides. Food Chemistry: Molecular Sciences, 3, 100047. https://doi.org/10.1016/j.fochms.2021.100047

- Kabir, M. F., Ju, L.-K. (2023). On optimization of enzymatic processes: Temperature effects on activity and long-term deactivation kinetics. Process Biochemistry, 130, 734–746. https://doi.org/10.1016/j.procbio.2023.05.031

- Yessengaziyeva, A. N., Uzakov, Y. M., Kuzembayeva, G. K., Kaimbayeva, L. A., Tlevlessova, D. A. (2023). The Use of the Protepsin Enzyme in the Production of Semi-Smoked Sausages. Journal of Culinary Science & Technology, 1–12. https://doi.org/10.1080/15428052.2023.2299027

- Yi, Y., Li, P., Zhao, F., Zhang, T., Shan, Y., Wang, X., Liu, B. et al. (2022). Current status and potentiality of class II bacteriocins from lactic acid bacteria: structure, mode of action and applications in the food industry. Trends in Food Science & Technology, 120, 387–401. https://doi.org/10.1016/j.tifs.2022.01.018

- López-Medina, F. A., Dublán-García, O., Morachis-Valdez, A. G., Saucedo-Vence, K., López-García, G., Díaz-Bandera, D., Gómez-Espinoza, R. M. (2025). Biopolymeric Hydrolysates from Dosidicus gigas: Functional Applications and Shelf-Life Extension in Squid Sausages. Polymers, 17 (7), 839. https://doi.org/10.3390/polym17070839

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Madina Kozhakhiyeva, Madina Kaldarbekova, Aliya Yessengaziyeva, Yasin Uzakov, Zhanar Medeubayeva, Gaukhar Kuzembayeva, Aziza Aitbayeva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.