Improving the model for determining the composition of gunpowder gases during thermal destruction of gunpowder in a limited volume space

DOI:

https://doi.org/10.15587/1729-4061.2025.330654Keywords:

thermal destruction of powder, powder gases, compressibility coefficient, equilibrium model, condensed carbonAbstract

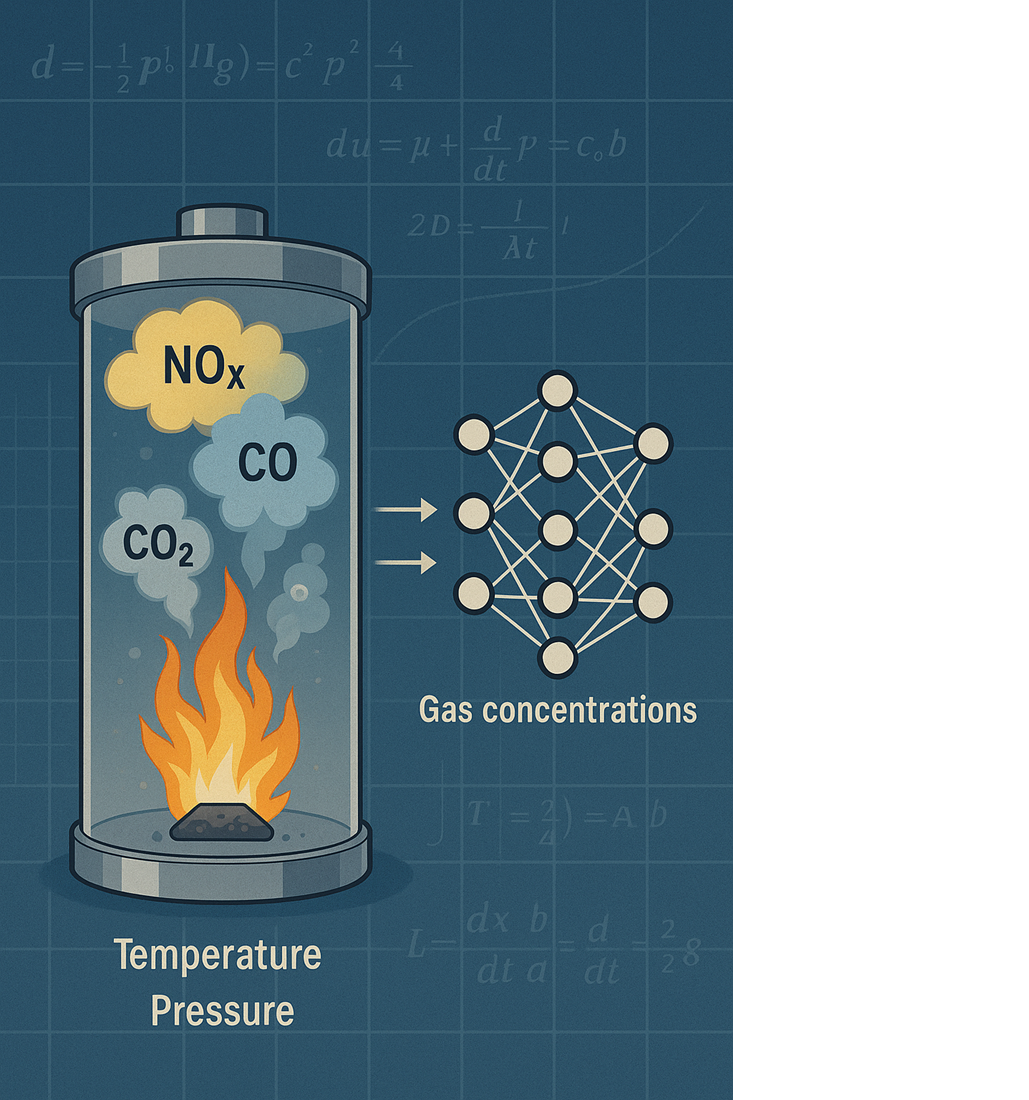

The object of this study is a model of the process of formation of products of thermal destruction of nitrocellulose powder at different values of pressure of the mixture of powder gases.

The work is aimed at eliminating the uncertainty in the list of powder combustion products. In many cases, the formation of condensed carbon during the shot is not taken into account, which does not correspond to the real process.

The process of formation of powder combustion products has been studied both under experimental conditions at a pressure of several MPa, and under shot conditions at a pressure of ~300 MPa and more. The proposed model makes it possible to explain the cause and conditions of condensed carbon formation. The possibility of formation of up to 10 % of condensed carbon from the initial mass of powder during the shot has been shown.

An improved model was built using the molar composition of the combustion products. The calculation of the specific volumes of gaseous reaction products with a change in the pressure of the gas mixture was carried out taking into account the change in their compressibility coefficient based on the Peng-Robinson equation. Within the limits of pressure values change during the shot process, the possibility of changing the equilibrium constant values in the range from ~40 % to twofold has been shown. The formation of condensed carbon is explained by the reaction of carbon monoxide disproportionation. The range of values of thermodynamic parameters of powder gases that ensure the possibility of this reaction was identified.

The proposed model could be used in the experimental determination of the composition and energy characteristics of a powder sample in the field based on the library method. Given the identified powder composition, the problem of internal ballistics could be solved for the prompt determination of shot parameters

References

- Paraschiv, T., Tiganescu, T. V., Iorga, G. O., Ginghina, R. E., Grigoroiu, O. C. (2020). Experimental and Theoretical Study on Three Combustion Models for the Determination of the Performance Parameters of Nitrocellulose - Based Propellants. Revista de Chimie, 71 (9), 87–97. https://doi.org/10.37358/rc.20.9.8320

- Kazandjian, L., Danel, J. (2006). A Discussion of the Kamlet‐Jacobs Formula for the Detonation Pressure. Propellants, Explosives, Pyrotechnics, 31 (1), 20–24. https://doi.org/10.1002/prep.200600002

- Appleton, R. J., Salek, P., Casey, A. D., Barnes, B. C., Son, S. F., Strachan, A. (2024). Interpretable Performance Models for Energetic Materials using Parsimonious Neural Networks. The Journal of Physical Chemistry A, 128 (6), 1142–1153. https://doi.org/10.1021/acs.jpca.3c06159

- Politzer, P., Murray, J. (2011). Some perspectives on estimating detonation properties of C, H, N, O compounds. Central European Journal of Energetic Materials, 8 (3), 209–220. Available at: https://www.researchgate.net/publication/279594253_Some_perspectives_on_estimating_detonation_properties_of_C_H_N_O_compounds

- Jensen, T. L., Moxnes, J. F., Unneberg, E., Dullum, O. (2014). Calculation of Decomposition Products from Components of Gunpowder by using ReaxFF Reactive Force Field Molecular Dynamics and Thermodynamic Calculations of Equilibrium Composition. Propellants, Explosives, Pyrotechnics, 39 (6), 830–837. https://doi.org/10.1002/prep.201300198

- Pantea, D., Brochu, S., Thiboutot, S., Ampleman, G., Scholz, G. (2006). A morphological investigation of soot produced by the detonation of munitions. Chemosphere, 65 (5), 821–831. https://doi.org/10.1016/j.chemosphere.2006.03.027

- Podlesak, D. W., Huber, R. C., Amato, R. S., Dattelbaum, D. M., Firestone, M. A., Gustavsen, R. L. et al. (2017). Characterization of detonation soot produced during steady and overdriven conditions for three high explosive formulations. AIP Conference Proceedings, 1793, 030006. https://doi.org/10.1063/1.4971464

- Yan, C., Zhu, C. (2023). Quantitative assessment method of muzzle flash and smoke at high noise level on field environment. Scientific Reports, 13 (1). https://doi.org/10.1038/s41598-023-27722-0

- Harries, M., Ang, H.-G. (2008). Software Development for the Detonation Product Analysis of High Energetic Materials - Part I. Central European Journal of Energetic Materials, 5 (3-4), 19–35. Available at: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=87178de51c47f3241bac52650b0952ac65a4b383

- Brunetkin, O., Maksymov, M., Brunetkin, V., Maksymov, О., Dobrynin, Y., Kuzmenko, V., Gultsov, P. (2021). Development of the model and the method for determining the influence of the temperature of gunpowder gases in the gun barrel for explaining visualize of free carbon at shot. Eastern-European Journal of Enterprise Technologies, 4 (1 (112)), 41–53. https://doi.org/10.15587/1729-4061.2021.239150

- Brunetkin, O., Maksymov, M., Dobrynin, Y., Demydenko, V., Sidelnykov, O. (2024). Development of a process model for determining the composition and energy characteristics of a pyrotechnic mixture using the library method. EUREKA: Physics and Engineering, 5, 99–112. https://doi.org/10.21303/2461-4262.2024.003453

- Brunetkin, O., Maksymov, M. V., Maksymenko, A., Maksymov, M. M. (2019). Development of the unified model for identification of composition of products from incineration, gasification, and slow pyrolysis. Eastern-European Journal of Enterprise Technologies, 4 (6 (100)), 25–31. https://doi.org/10.15587/1729-4061.2019.176422

- Thermodynamic and thermophysical properties of combustion products (1974). Israel Program for Scientific Translations. Available at: https://searchworks.stanford.edu/view/892711

- Brunetkin, O., Davydov, V., Butenko, O., Lysiuk, G., Bondarenko, A. (2019). Determining the composition of burned gas using the method of constraints as a problem of model interpretation. Eastern-European Journal of Enterprise Technologies, 3 (6 (99)), 22–30. https://doi.org/10.15587/1729-4061.2019.169219

- Mianowski, A., Robak, Z., Tomaszewicz, M., Stelmach, S. (2012). The Boudouard–Bell reaction analysis under high pressure conditions. Journal of Thermal Analysis and Calorimetry, 110 (1), 93–102. https://doi.org/10.1007/s10973-012-2334-2

- Kotov, V. G., Sviatenko, O. M., Khovavko, A. I., Nebesniy, A. A., Filonenko, D. S. (2014). Thermodynamics of Carbon-Black For- mation Process at High Hydrogen Concentration in Gas which Contains Carbon Monoxide. Energy technologies and resource savings, 1, 38–43. Available at: http://dspace.nbuv.gov.ua/handle/123456789/127270

- Karaeva, A. R., Khaskov, M. A., Mitberg, E. B., Kulnitskiy, B. A., Perezhogin, I. A., Ivanov, L. A. et al. (2012). Longer Carbon Nanotubes by Controlled Catalytic Growth in the Presence of Water Vapor. Fullerenes, Nanotubes and Carbon Nanostructures, 20 (4-7), 411–418. https://doi.org/10.1080/1536383x.2012.655229

- Rout, K. R., Gil, M. V., Chen, D. (2019). Highly selective CO removal by sorption enhanced Boudouard reaction for hydrogen production. Catalysis Science & Technology, 9 (15), 4100–4107. https://doi.org/10.1039/c9cy00851a

- Maksimov, M. V., Brunetkin, O. I., Lysyuk, O. V., Tarakhtiy, O. S. (2017). Pat. No. 120216 UA. Installation for Determining the Composition of Combustible Gas in the Process of Combustion. No. а201712785; declareted: 22.12.2017; published: 11.06.2018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Olexander Brunetkin, Oleksandr Sidelnykov, Maksym Maksymov, Yevhenii Dobrynin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.