Estimating the influence of polyorganosiloxanes on the properties of fire-retardant halogen-free polymer compositions for cable articles

DOI:

https://doi.org/10.15587/1729-4061.2025.331134Keywords:

cable articles, fire-resistant polymer compositions, polyorganosiloxanes, rheological properties, thermophysical propertiesAbstract

The object of this study is the processes of supramolecular structure formation and the thermophysical, rheological, physical-mechanical, and electrophysical properties of halogen-free fire-resistant polymer compositions. Aluminum oxide trihydrate is used as a flame retardant. The effect of the flame-retardant filler becomes noticeable only with a significant filling (60%), when the rheological and operational properties of polymer compositions deteriorate. The use of polyorganosiloxanes makes it possible to reduce the negative impact of the filler on the thermophysical, rheological, physical-mechanical, and electrophysical properties. Therefore, the effective use of polyorganosiloxanes to regulate the properties of fire-resistant polymer compositions is an urgent task under consideration.

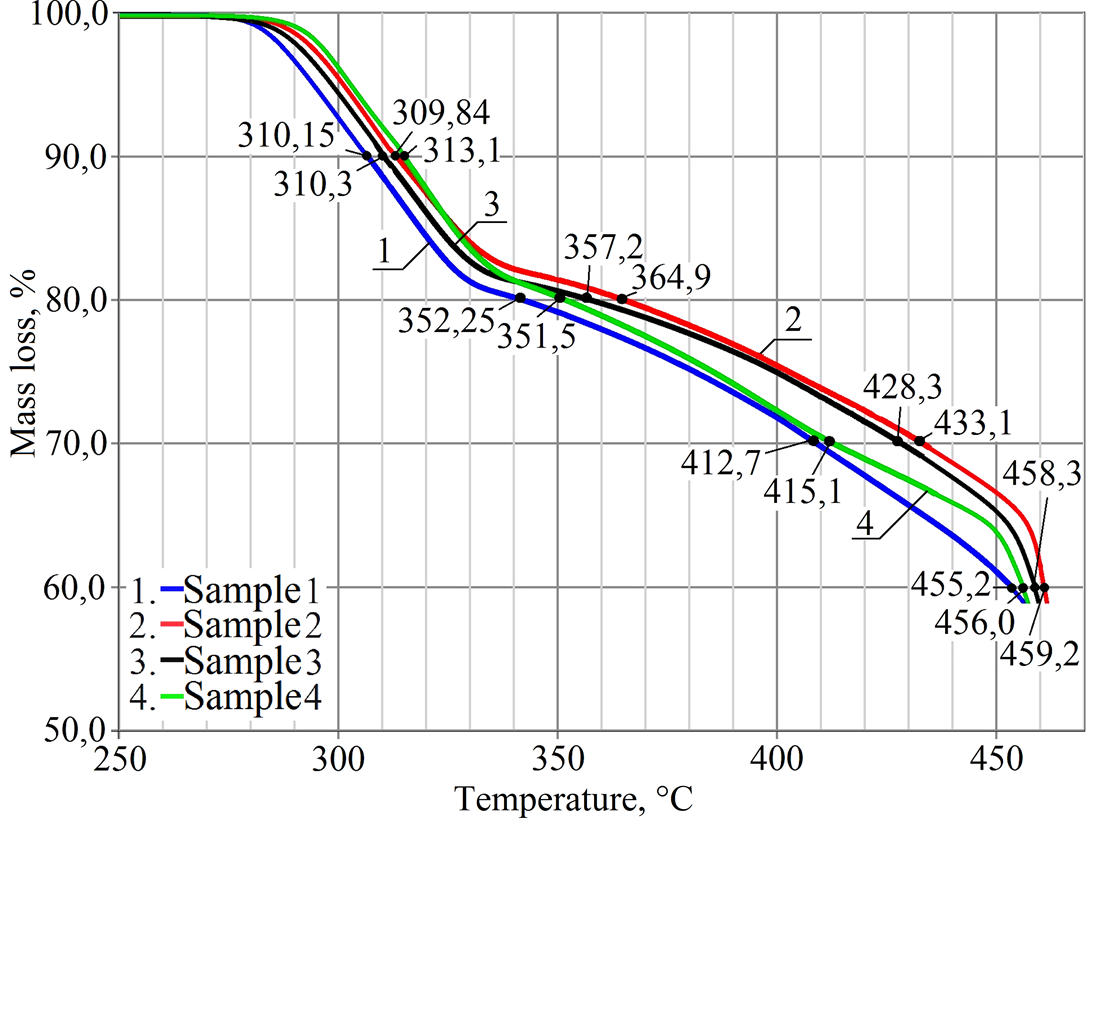

Fire retardant halogen-free polymer compositions were studied. The content of the flame-retardant filler is 60%. The samples under study additionally contain polyorganosiloxanes, which were used as modifiers for the directed regulation of properties of fire retardant compositions. The effect of polyorganosiloxanes on the formation of the supramolecular structure of filled polymer compositions for cable articles has been established. Due to this, the phase transition temperatures increase by 2–4°C, the temperature of the beginning of decomposition by 12–17°C and the end of decomposition by 5–6°C. The effect of the influence of polyorganosiloxanes with a viscosity of 50–500 Pa·s on a decrease in the melt viscosity of fire retardant polymer compositions from 5.342 to 4.330 Pa·s with an increase in the shear rate from 20 to 60 s-1 has been shown.

The results make it possible to use polyorganosiloxanes for targeted regulation of rheological and operational characteristics of fire-resistant polymer compositions for the manufacture of insulation and sheath of power cables

References

- Meinier, R., Sonnier, R., Zavaleta, P., Suard, S., Ferry, L. (2018). Fire behavior of halogen-free flame retardant electrical cables with the cone calorimeter. Journal of Hazardous Materials, 342, 306–316. https://doi.org/10.1016/j.jhazmat.2017.08.027

- Gupta, R., Singh, M. K., Rangappa, S. M., Siengchin, S., Dhakal, H. N., Zafar, S. (2024). Recent progress in additive inorganic flame retardants polymer composites: Degradation mechanisms, modeling and applications. Heliyon, 10 (21), e39662. https://doi.org/10.1016/j.heliyon.2024.e39662

- Semenyuk, K. A. (2017). Tehnologicheskie aspekty v reshenii voprosa snizheniya goryuchesti kompozicionnyh materialov. Pozhezhna ta tekhnohenna bezpeka. Materialy vseukrainskoi naukovo-praktychnoi konferentsiyi kursantiv i studentiv. Cherkasy, 92–93. Available at: https://nuczu.edu.ua/images/topmenu/science/konferentsii/2017/2.pdf

- Lu, S.-Y., Hamerton, I. (2002). Recent developments in the chemistry of halogen-free flame retardant polymers. Progress in Polymer Science, 27 (8), 1661–1712. https://doi.org/10.1016/s0079-6700(02)00018-7

- Sonnier, R., Viretto, A., Dumazert, L., Longerey, M., Buonomo, S., Gallard, B. et al. (2016). Fire retardant benefits of combining aluminum hydroxide and silica in ethylene-vinyl acetate copolymer (EVA). Polymer Degradation and Stability, 128, 228–236. https://doi.org/10.1016/j.polymdegradstab.2016.03.030

- . Nazir, R., Gooneie, A., Lehner, S., Jovic, M., Rupper, P., Ott, N. et al. (2021). Alkyl sulfone bridged phosphorus flame-retardants for polypropylene. Materials & Design, 200, 109459. https://doi.org/10.1016/j.matdes.2021.109459

- Chulieieva, O. V., Plavan, V. P. (2019). Modeliuvannia teplofizychnykh vlastyvostei napovniuvachiv pozhezhobezpechnykh polimernykh kompozytsiy. Materialy IX mizhnarodnoi naukovo-praktychnoi konferentsiyi «Kompleksne zabezpechennia yakosti tekhnolohichnykh protsesiv ta system». Vol. 2. Chernihiv, 19–21. Available at: https://drive.google.com/file/d/107ctOF8LwQWSF8W2yECrxrQm9etpkMF5/view

- Ye, L., Miao, Y., Yan, H., Li, Z., Zhou, Y., Liu, J., Liu, H. (2013). The synergistic effects of boroxo siloxanes with magnesium hydroxide in halogen-free flame retardant EVA/MH blends. Polymer Degradation and Stability, 98 (4), 868–874. https://doi.org/10.1016/j.polymdegradstab.2013.01.001

- VISCOSPEED in HFFR compounds: Big impact with minimal dosage (2020). Compounding World. Available at: https://viscospeed.com/wp-content/uploads/2021/05/Compounding_World_Article_VISCOSPEED.pdf

- El Omari, Y., Yousfi, M., Duchet-Rumeau, J., Maazouz, A. (2023). Interfacial rheology for probing the in-situ chemical reaction at interfaces of molten polymer systems. Materials Today Communications, 35, 105640. https://doi.org/10.1016/j.mtcomm.2023.105640

- Xu, J., Chen, C., Li, Y., Zhou, H., Hao, X., Ou, R., Wang, Q. (2024). Optimizing the rheological and mechanical properties of ultra-highly filled wood fiber/polyethylene composites through binary alloy matrix strategy. Composites Science and Technology, 256, 110740. https://doi.org/10.1016/j.compscitech.2024.110740

- Bashirgonbadi, A., Delva, L., Caron, E., Marchesini, F. H., Van Geem, K. M., Ragaert, K. (2024). The interplay between macromolecular structure, rheology, processing condition, and morphology for (linear) low density polyethylenes in film blowing. Polymer, 290, 126566. https://doi.org/10.1016/j.polymer.2023.126566

- Cardelli, A., Ruggeri, G., Calderisi, M., Lednev, O., Cardelli, C., Tombari, E. (2012). Effects of poly(dimethylsiloxane) and inorganic fillers in halogen free flame retardant poly(ethylene-co-vinyl acetate) compound: A chemometric approach. Polymer Degradation and Stability, 97 (12), 2536–2544. https://doi.org/10.1016/j.polymdegradstab.2012.02.018

- Rusanova, S., Stoyanov, O., Sofina, S., Zaikov, G. (2013). IR-Study of Silanol Modification of Ethylene Copolymers. Chemistry & Chemical Technology, 7 (1), 23–26. https://doi.org/10.23939/chcht07.01.023

- Rueda, M. M., Auscher, M.-C., Fulchiron, R., Périé, T., Martin, G., Sonntag, P., Cassagnau, P. (2017). Rheology and applications of highly filled polymers: A review of current understanding. Progress in Polymer Science, 66, 22–53. https://doi.org/10.1016/j.progpolymsci.2016.12.007

- Adesina, A. A., Nasser, M. N., Teixeira, P., Hilliou, L., Covas, J. A., Hussein, I. A. (2015). Rheology of organoclay assisted extrusion of HDPE using Particle Image Velocimetry. Chemical Engineering Research and Design, 100, 113–125. https://doi.org/10.1016/j.cherd.2015.05.018

- Faker, M., Razavi Aghjeh, M. K., Ghaffari, M., Seyyedi, S. A. (2008). Rheology, morphology and mechanical properties of polyethylene/ethylene vinyl acetate copolymer (PE/EVA) blends. European Polymer Journal, 44 (6), 1834–1842. https://doi.org/10.1016/j.eurpolymj.2008.04.002

- Durmus, A., Kasgoz, A., Macosko, C. W. (2007). Linear low density polyethylene (LLDPE)/clay nanocomposites. Part I: Structural characterization and quantifying clay dispersion by melt rheology. Polymer, 48 (15), 4492–4502. https://doi.org/10.1016/j.polymer.2007.05.074

- Münstedt, H. (2021). Rheological Measurements and Structural Analysis of Polymeric Materials. Polymers, 13 (7), 1123. https://doi.org/10.3390/polym13071123

- Münstedt, H. (2016). Rheological and Morphological Properties of Dispersed Polymeric Materials. Rheological and Morphological Properties of Dispersed Polymeric Materials, I–XVI. https://doi.org/10.3139/9781569906088.fm

- Agassant, J.-F., Avenas, P., Carreau, P. J., Vergnes, B., Vincent, M. (2017). Polymer Processing. Verlag: Carl Hanser Verlag GmbH & Co. KG. https://doi.org/10.3139/9781569906064

- Zhou, C., Yi, H., Dong, X. (2017). Review of recent research towards power cable life cycle management. High Voltage, 2 (3), 179–187. https://doi.org/10.1049/hve.2017.0037

- Karaki, A., Hammoud, A., Masad, E., Khraisheh, M., Abdala, A., Ouederni, M. (2024). A review on material extrusion (MEX) of polyethylene - Challenges, opportunities, and future prospects. Polymer, 307, 127333. https://doi.org/10.1016/j.polymer.2024.127333

- Morsalin, S., Phung, B. T. (2020). Dielectric response study of service-aged XLPE cable based on polarisation and depolarisation current method. IEEE Transactions on Dielectrics and Electrical Insulation, 27 (1), 58–66. https://doi.org/10.1109/tdei.2019.008306

- Morsalin, S., Phung, T. B., Danikas, M., Mawad, D. (2019). Diagnostic challenges in dielectric loss assessment and interpretation: a review. IET Science, Measurement & Technology, 13 (6), 767–782. https://doi.org/10.1049/iet-smt.2018.5597

- Holoborodko, L. V., Zhurenko, A. Yu., Kutsomelia, Yu. Yu., Litsman, Yu. V. (2007). Poliorhanosyloksany i materialy na yikh osnovi. Materialy naukovo-tekhnichnoi konferentsii vykladachiv, spivrobinykiv, aspirantiv i studentiv inzhenernoho fakultetu. Sumy, 10–11. Available at: https://essuir.sumdu.edu.ua/handle/123456789/19009

- Schramm, G. (1994). A Practical Approach to Rheology and Rheometry. Gebrueder Haake, 290.

- Kuzyaev, I. M., Sviderskiy, V. A., Petuhov, A. D. (2016). Modelirovanie ekstruzii i ekstruderov pri pererabotke polimerov. Ch. 1. Kyiv: NTUU«KPI», 414. Available at: https://ela.kpi.ua/items/8bd0c55e-f776-41a9-9682-9eccc574c3fd

- Chulieieva, O., Zolotaryov, V. (2018). Regulation of electrophysical properties of fireproof polymer compositions filled with hydromagnesite for cable products. Technology Audit and Production Reserves, 2 (1 (46)), 21–23. https://doi.org/10.15587/2312-8372.2019.161856

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Volodymyr Zolotaryov, Olena Chulieieva, Taras Antonets

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.