Evaluating of the sudden heat impact on volatile gases release during the gasification process of weakly grade metamorphized coal

DOI:

https://doi.org/10.15587/1729-4061.2025.331223Keywords:

weakly grade metamorphized coal, sudden heat, distortion energy, thermogravimetric analysis, thermal stressAbstract

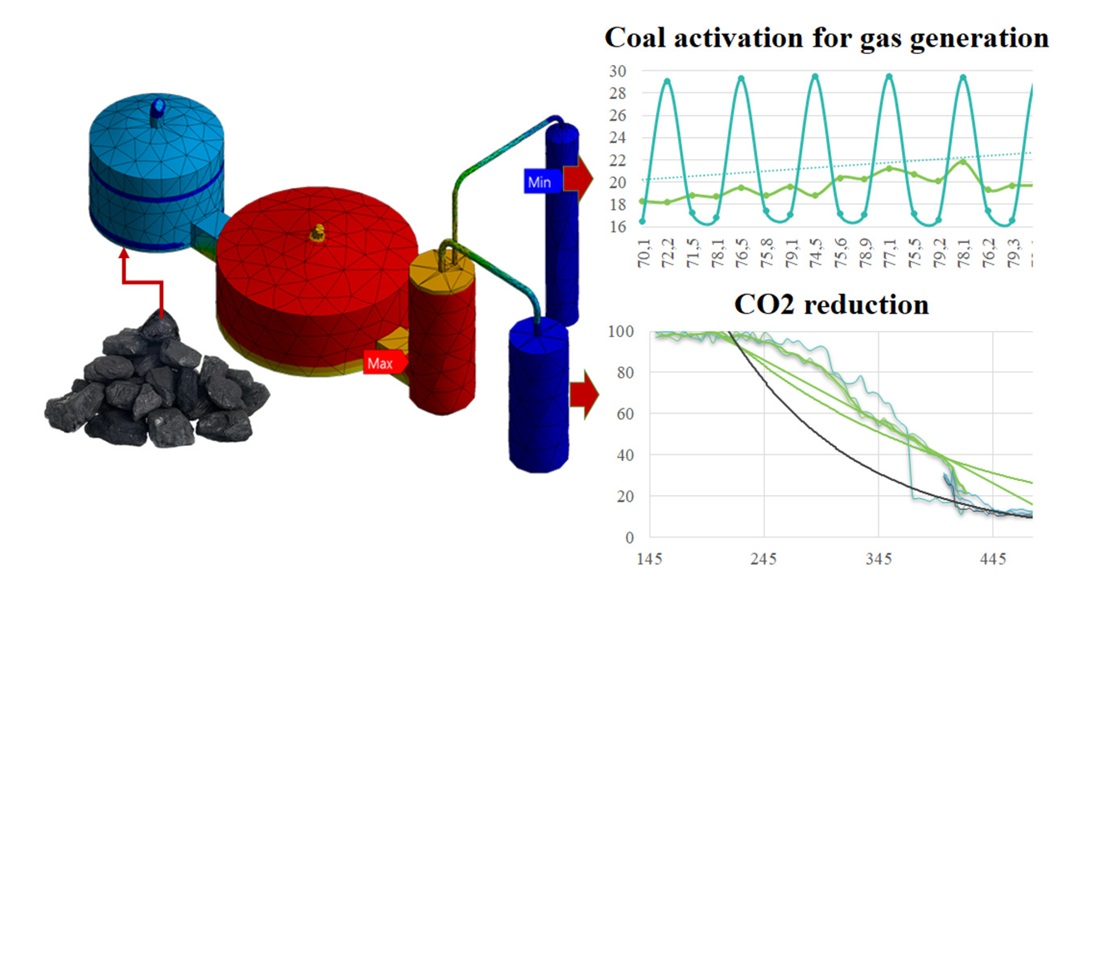

The object of research is a low-temperature gasification technology of weakly grade metamorphized coals. One of the outstanding issues of the low-temperature gasification technology of weakly grade metamorphized coals remains the long processing period due to the coal weak energy activation directly dependent on the release of volatile gases, which depend on isotropic state of coal. The problem that was solved is to scale up coal activation energy through the sudden heat during thermal processing. The results obtained show a shift of the volatile gases release beginning to a temperature of 410°C in the same quantity as with the step-by-step heating to a temperature of 500°C. In addition, the sudden heat contributes to a reduction of CO2 emissions by 12%, indicating an improvement in environmental performance. These results are explained by the fact that a sharp difference in temperatures of 20°C and 400°C creates conditions for the appearance of energy distortion in the isotropic zones of the coal body heating. This energy weakens and destroys the internal bonds between the coal particles and creates conditions for the release of new volatile elements at lower temperatures.

The main features of the results obtained, which made it possible to solve the problem studied are the results on transformation of thermal stresses into energy of distortion at the sudden heat in the relationship between the mechanics and physics of anisotropic coal. The scope and conditions of practical use of the results obtained is will allow for the adjustment of gasification techniques for coals with low degree of metamorphism and the establishment of gasification regimes, taking into account the design and capacity of the gasifiers

References

- Wang, Y., Schaffers, W. C., Tan, S., Kim, J. S., Boardman, R. D., Bell, D. A. (2020). Low temperature heating and oxidation to prevent spontaneous combustion using Powder River Basin coal. Fuel Processing Technology, 199, 106221. https://doi.org/10.1016/j.fuproc.2019.106221

- Wang, Y., Sun, Y., Dai, L., Wang, K., Cheng, G. (2023). Mechanisms of CO and CO2 Production during the Low-Temperature Oxidation of Coal: Molecular Simulations and Experimental Research. Fire, 6 (12), 475. https://doi.org/10.3390/fire6120475

- Song, H., Liu, G., Zhang, J., Wu, J. (2017). Pyrolysis characteristics and kinetics of low rank coals by TG-FTIR method. Fuel Processing Technology, 156, 454–460. https://doi.org/10.1016/j.fuproc.2016.10.008

- Zhu, Y., Li, K., Wang, Q., Cen, J., Fang, M., Luo, Z. (2022). Low-rank coal pyrolysis polygeneration technology with semi-coke heat carrier based on the dual-fluidized bed to co-produce electricity, oil and chemical products: Process simulation and techno-economic evaluation. Fuel Processing Technology, 230, 107217. https://doi.org/10.1016/j.fuproc.2022.107217

- Zang, C., Zhou, J., Chen, M., Bai, F., Zhao, Z. (2023). Study on the Instability Mechanism of Coal and Rock Mining under a Residual Coal Pillar in Gently Inclined Short-Distance Coal Seam with the Discrete Element. Sustainability, 15 (7), 6294. https://doi.org/10.3390/su15076294

- Zhou, H., Yao, J., Chen, S., Li, H., Chen, Y., Wu, X. (2024). Effect of moisture content on charging and triboelectrostatic separation of coal gasification fine ash. Separation and Purification Technology, 333, 125976. https://doi.org/10.1016/j.seppur.2023.125976

- Liu, H., Li, M., Zhao, S., Jiang, L., Xu, Q., Majlingová, A. (2024). Applications of distributed activation energy model on the pyrolysis of green renewable wood. Fuel, 359, 130457. https://doi.org/10.1016/j.fuel.2023.130457

- Zhang, T., Zhang, C., Ren, H., Huang, Z., Feng, J., Liu, N. et al. (2025). Co-pyrolysis of coal-derived sludge and low-rank coal: Thermal behaviour and char yield prediction. Fuel Processing Technology, 267, 108165. https://doi.org/10.1016/j.fuproc.2024.108165

- Xu, D., Yang, L., Liu, H., Sun, S., Ma, M., Zhi, Y. (2024). Co-pyrolysis characteristics and kinetics of rice straw and low rank coal. Journal of Analytical and Applied Pyrolysis, 183, 106741. https://doi.org/10.1016/j.jaap.2024.106741

- Аtyaksheva, А., Rozhkova, O., Sarsikeyev, Y., Atyaksheva, A., Yermekov, M., Smagulov, A., Ryvkina, N. (2022). Determination of rational parameters for heat treatment of concrete mixture based on a hollow aluminosilicate microsphere. Eastern-European Journal of Enterprise Technologies, 1 (6 (115)), 64–72. https://doi.org/10.15587/1729-4061.2022.251004

- Zhang, L., Wang, G., Xue, Q., Zuo, H., She, X., Wang, J. (2021). Effect of preheating on coking coal and metallurgical coke properties: A review. Fuel Processing Technology, 221, 106942. https://doi.org/10.1016/j.fuproc.2021.106942

- Zhang, J., Zhu, J., Liu, J. (2023). Experimental Studies on Preheating Combustion Characteristics of Low-Rank Coal with Different Particle Sizes and Kinetic Simulation of Nitrogen Oxide. Energies, 16 (20), 7078. https://doi.org/10.3390/en16207078

- Mergalimova, A., Atyaksheva, A., Sultan, Y., Nursultan, S. (2024). Identification of the low-rank coals thermal heating behavior. Eastern-European Journal of Enterprise Technologies, 2 (6 (128)), 39–48. https://doi.org/10.15587/1729-4061.2024.299538

- Atyaksheva, A. V., Atyaksheva, A. D., Ryvkina, N. V., Yermekov, M. T., Rozhkova, O. V., Smagulov, A. S. (2022). Effectiveness analysis of Maikuben brown coal combustion in the heating boiler “Kamkor-300.” Journal of Physics: Conference Series, 2211 (1), 012003. https://doi.org/10.1088/1742-6596/2211/1/012003

- Fu, D., Yu, Z., Gao, K., Duan, Z., Wang, Z., Guo, W., Yang, P. et al. (2023). Thermodynamic Analysis on In Situ Underground Pyrolysis of Tar-Rich Coal: Secondary Reactions. ACS Omega, 8 (14), 12805–12819. https://doi.org/10.1021/acsomega.2c08033

- Zhang, W., Zeng, Q. (2023). Characteristics of coal oxidation and spontaneous combustion in Baishihu Mine, Xinjiang, China. Frontiers in Earth Science, 11. https://doi.org/10.3389/feart.2023.1208803

- Kijo-Kleczkowska, A., Szumera, M., Gnatowski, A., Sadkowski, D. (2022). Comparative thermal analysis of coal fuels, biomass, fly ash and polyamide. Energy, 258, 124840. https://doi.org/10.1016/j.energy.2022.124840

- Deng, H., Zhou, H., Li, L. (2022). Fractional creep model of temperature-stress-time coupled damage for deep coal based on temperature-equivalent stress. Results in Physics, 39, 105765. https://doi.org/10.1016/j.rinp.2022.105765

- Chao, J., Liu, S., Pan, R., Yuan, Y., Hu, D. (2024). Study on the thermal effect of coal oxidation under different stresses. Science of The Total Environment, 915, 169843. https://doi.org/10.1016/j.scitotenv.2023.169843

- Wang, X., Qi, X., Ma, H., Li, S. (2023). Experimental Investigation on the Influence of Temperature on Coal and Gas Outbursts. Processes, 11 (6), 1687. https://doi.org/10.3390/pr11061687

- Ul’yanova, E. V., Malinnikova, O. N., Pashichev, B. N., Malinnikova, E. V. (2019). Microstructure of Coal before and after Gas-Dynamic Phenomena. Journal of Mining Science, 55 (5), 701–707. https://doi.org/10.1134/s1062739119056063

- Rothleutner, L. (2018). Distortion during heating. Minimizing distortion involves more than just optimizing cooling. Thermal processing. Available at: https://thermalprocessing.com/metal-urgency-distortion-during-heating

- Bryan, W. A., Calvert, C. R., King, R. B., Nemeth, G. R. A. J., Greenwood, J. B., Williams, I. D., Newell, W. R. (2010). Quasi-classical model of non-destructive wavepacket manipulation by intense ultrashort nonresonant laser pulses. New Journal of Physics, 12 (7), 073019. https://doi.org/10.1088/1367-2630/12/7/073019

- Kou, B., Shi, Q., Wang, S., Sun, Q., Cui, S., Yang, X. et al. (2025). Axial pressure impact on pyrolysis behavior of Xinjiang coal: An inspiration for in-situ pyrolysis of tar-rich coal. Fuel Processing Technology, 267, 108175. https://doi.org/10.1016/j.fuproc.2024.108175

- Su, C., Qiu, J., Wu, Q., Weng, L. (2020). Effects of high temperature on the microstructure and mechanical behavior of hard coal. International Journal of Mining Science and Technology, 30 (5), 643–650. https://doi.org/10.1016/j.ijmst.2020.05.021

- Donskoy, I. G. (2014). Modelirovanie i optimizaciya rezhimov raboty gazogeneratora plotnogo sloya dlya parogeneratorov mini-TES. FBGUN. Irkytsk.

- Ybray, S. (2022). Otchet po nauchnoj stazhirovke v Institute uglekhimii i himicheskogo materialovedeniya Federal'nogo issledovatel'skogo centra uglya i uglekhimii SO RAN.

- Li, W., Yu, Z., Guan, G. (2021). Catalytic coal gasification for methane production: A review. Carbon Resources Conversion, 4, 89–99. https://doi.org/10.1016/j.crcon.2021.02.001

- Mishra, A., Gautam, S., Sharma, T. (2018). Effect of operating parameters on coal gasification. International Journal of Coal Science & Technology, 5 (2), 113–125. https://doi.org/10.1007/s40789-018-0196-3

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Аlexandra Аtyaksheva, Anastassiya Dashevskaya, Almagul Mergalimova, Sultan Ybray, Maralgul Aitmagambetova, Ruslan Umirzakov, Zhenis Sultanbek

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.