Devising a method for controlling articles during photopolymer 3D printing

DOI:

https://doi.org/10.15587/1729-4061.2025.335706Keywords:

LCD technology, photopolymer printing, additive manufacturing, defects, automated control, thermal modelAbstract

This study’s object is those factors that affect the defects of photopolymer 3D models. The task addressed relates to identifying the factors that cause the appearance of surface defects and deviations in geometric dimensions in photopolymer 3D models.

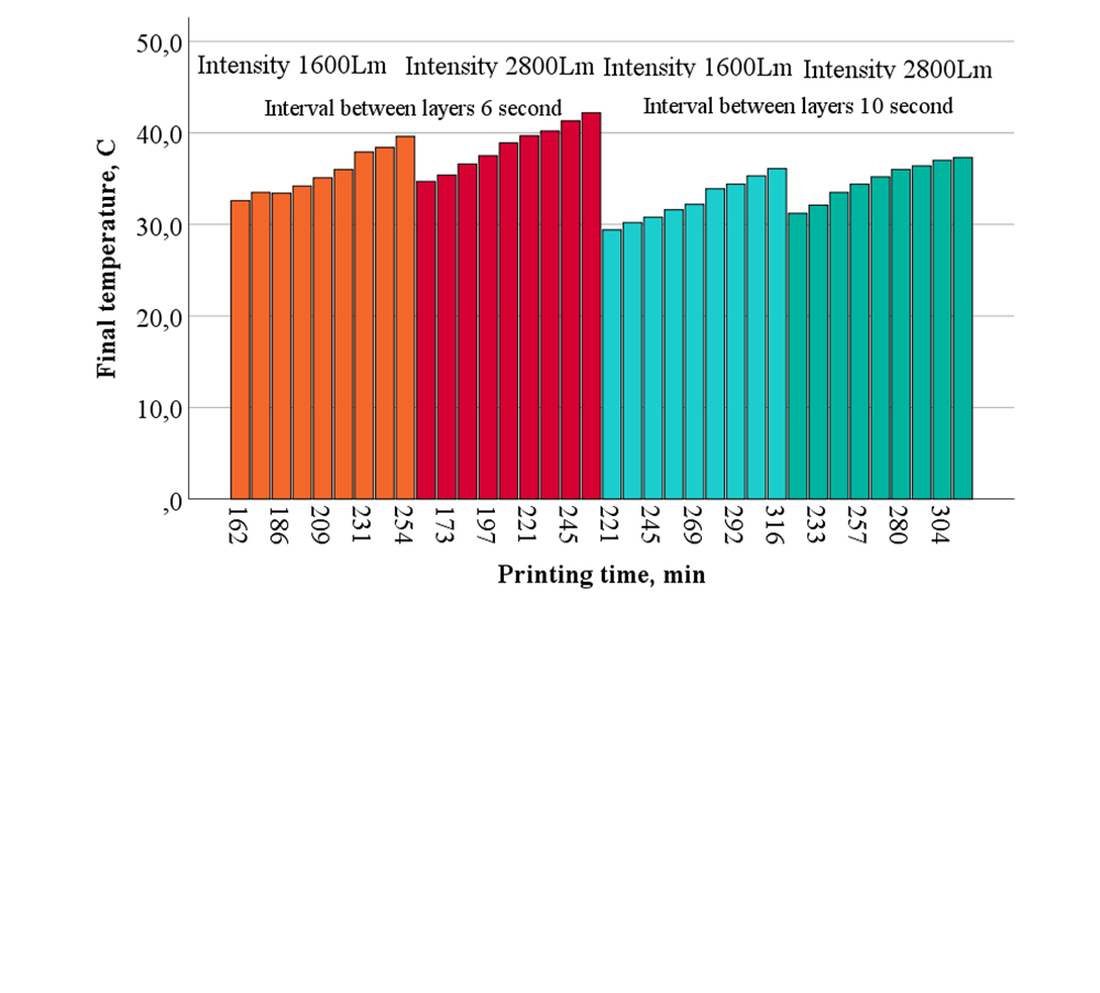

The influence of the photopolymer resin temperature on the surface defects appearance and deviations in geometric dimensions, as well as the layers exposure parameters influence on the photopolymer resin temperature, has been revealed. At the final stage of the study, it was found that the exposure parameters of the photopolymer model layers affect the photopolymer resin temperature, which, in turn, increases the likelihood of defects and geometric deviations in the finished model. Provided that the photopolymer resin temperature is kept within the range of 18–26°C, the model dimensions geometric deviation decreases by 0.054 mm along the XY axis and by 0.006 mm along the Z axis. A linear dependence of the size deviations on the exposure parameters and the photopolymer resin temperature has been established.

The process of heat transfer from a UV radiation source to a photopolymer resin has been described. A thermodynamic scheme for controlling the resin temperature based on modeling the heat transfer between the exposed layers and the resin volume, considering the exposure time and UV radiation intensity, has been devised, which makes it possible to predict a critical temperature increase and minimize defects.

While devising a method for controlling products during photopolymer 3D printing, the photopolymer temperature parameter was considered as one of the factors affecting the quality of parts and the level of rejects. Thus, the proposed method for controlling products during photopolymer 3D printing could be used to improve the technological process of manufacturing parts by reducing the number of defects and improving the finished products quality

References

- Nevliudov, I. Sh., Zharikova, I. V., Perepelitca, I. D., Reznichenko, A. G. (2014). The analysis of the electronic devices substrates roughness testing methods. Eastern-European Journal of Enterprise Technologies, 2 (5 (68)), 25–30. https://doi.org/10.15587/1729-4061.2014.21864

- Polozova, T., Romanenkov, Y., Sheiko, I., Buiak, L., Murzabulatova, O., Ponomarov, S. (2024). Industrial Development in the Era of Digital Technologies: a Comparative Analysis of EU States. 2024 14th International Conference on Advanced Computer Information Technologies (ACIT). Ceske Budejovice: IEEE, 419–422. https://doi.org/10.1109/acit62333.2024.10712520

- Nevliudov, I. Sh., Chala, O. O., Botsman, I. V. (2021). Determination of technological process modes for surface formation of substrates for functional components of microoptoelectromechanical systems. Functional Materials, 28 (2), 381–385. https://doi.org/10.15407/fm28.02.381

- Zhao, X., Zhao, Y., Li, M.-D., Li, Z., Peng, H., Xie, T. et al. (2021). Efficient 3D printing via photooxidation of ketocoumarin based photopolymerization. Nature Communications, 12 (1). https://doi.org/10.1038/s41467-021-23170-4

- Jacobsen, A., Jorgensen, T., Tafjord, Ø., Kirkhorn, E. (2015). Concepts for 3D print productivity systems with advanced DLP photoheads. Emerging Digital Micromirror Device Based Systems and Applications VII. SPIE, 9376, 937605. https://doi.org/10.1117/12.2084962

- Shafique, H., Karamzadeh, V., Kim, G., Shen, M. L., Morocz, Y., Sohrabi-Kashani, A. et al. (2024). High-resolution low-cost LCD 3D printing for microfluidics and organ-on-a-chip devices. Lab on a Chip, 24 (10), 2774–2790. https://doi.org/10.1039/d3lc01125a

- Nevliudov, I. Sh., Nikitin, D. O., Strilets, R. Ye. (2025). Rozrobka systemy avtomatyzovanoho keruvannia fotopolimernym 3D‑drukom. Avtomatyzatsiia ta kompiuterno‑intehrovani tekhnolohii – 2025. Kyiv: KPI im. Ihoria Sikorskoho, Vyd-vo «Politekhnika», 86–87.

- Fiedor, P., Pilch, M., Szymaszek, P., Chachaj-Brekiesz, A., Galek, M., Ortyl, J. (2020). Photochemical Study of a New Bimolecular Photoinitiating System for Vat Photopolymerization 3D Printing Techniques under Visible Light. Catalysts, 10 (3), 284. https://doi.org/10.3390/catal10030284

- Tomal, W., Pilch, M., Chachaj-Brekiesz, A., Ortyl, J. (2019). Development of New High-Performance Biphenyl and Terphenyl Derivatives as Versatile Photoredox Photoinitiating Systems and Their Applications in 3D Printing Photopolymerization Processes. Catalysts, 9 (10), 827. https://doi.org/10.3390/catal9100827

- Livesu, M., Ellero, S., Martínez, J., Lefebvre, S., Attene, M. (2017). From 3D models to 3D prints: an overview of the processing pipeline. Computer Graphics Forum, 36 (2), 537–564. https://doi.org/10.1111/cgf.13147

- Nikitin, D. O., Balabanov, I. V. (2024). Doslidzhennia vplyvu temperatury fotopolimernoi smoly na zberezhennia heometrychnykh rozmiriv modeli pid chas 3D druku. Science of XXI century: development, main theories and achievements. Helsinki: International Center of Scientific Research, 197–203. Available at: https://previous.scientia.report/index.php/archive/issue/view/26.01.2024

- Nevliudov, I., Razumov-Frizyuk, I., Nikitin, D., Badaniuk, I., Strelets, R.; Linde, I. (Ed.) (2023). Practical results of the study of photopolymer exposure of printed circuit board topology. Information Systems in Project and Program Management. Riga: European University Press, 262–280. https://doi.org/10.30837/mmp.2023.262

- Nikitin, D. (2024). Development of a model for controlling the temperature of photopolymer resin based on LCD 3D printing technology. Control, Navigation and Communication Systems, 1 (75), 31–37. https://doi.org/10.26906/sunz.2024.1.031

- Born, M., Wolf, E. (2013). Principles of optics: Electromagnetic theory of propagation, interference, and diffraction of light. Elsevier, 836.

- Reddy, J. N. (2014). An Introduction to Nonlinear Finite Element Analysis: with applications to heat transfer, fluid mechanics, and solid mechanics Oxford University Press. https://doi.org/10.1093/acprof:oso/9780199641758.001.0001

- Ruban, I., Horenskyi, H., Romanenkov, Y., Revenko, D. (2022). Models of adaptive integration of weighted interval data in tasks of predictive expert assessment. Eastern-European Journal of Enterprise Technologies, 5 (4 (119)), 6–15. https://doi.org/10.15587/1729-4061.2022.265782

- Salcedo, J., McCormick, K. (2020). SPSS Statistics for Dummies. Hoboken: John Wiley & Sons. Available at: https://www.wiley.com/en-us/SPSS+Statistics+For+Dummies%2C+4th+Edition-p-9781119560821

- Keviczky, L., Bars, R., Hetthéssy, J., Bányász, C. (2019). Control Engineering. Advanced Textbooks in Control and Signal Processing. Singapore: Springer, 532. https://doi.org/10.1007/978-981-10-8297-9

- Ziaziun, I. A. et al. (Eds.) (Suchasni informatsiini tekhnolohii ta innovatsiini metodyky navchannia u pidhotovtsi fakhivtsiv: metodolohiia, teoriia, dosvid, problemy). Kyiv-Vinnytsia: TOV firma «Planer», 39, 514. Available at: https://library.vspu.net/items/e39efe6a-1bd9-445a-af11-eb357fdba890

- Hahn, B. H., Valentine, D. T. (2017). Essential MATLAB for Engineers and Scientists. Academic Press. https://doi.org/10.1016/C2015-0-02182-7

- Díaz-Rodríguez, I. D., Han, S., Bhattacharyya, S. P. (2019). Analytical Design of PID Controllers. Cham: Springer International Publishing, 302. https://doi.org/10.1007/978-3-030-18228-1

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dmytro Nikitin, Igor Nevliudov, Iryna Zharikova, Artem Bronnikov, Roman Strelets

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.