Evaluation of deformation characteristics and bearing capacity assessment of crushed-rock backfill with various grain size distributions

DOI:

https://doi.org/10.15587/1729-4061.2024.337172Keywords:

grain-size distribution, crushed rock, compressive compaction, complete backfilling of the gob areaAbstract

This study addresses issues related to deformation processes in crushed rock backfills, which are used to control the condition of surrounding rocks in the extraction areas of coal mines.

The task under consideration is to maintain mine roadway stability by preventing roof collapses in the gob area by ensuring the bearing capacity of backfills.

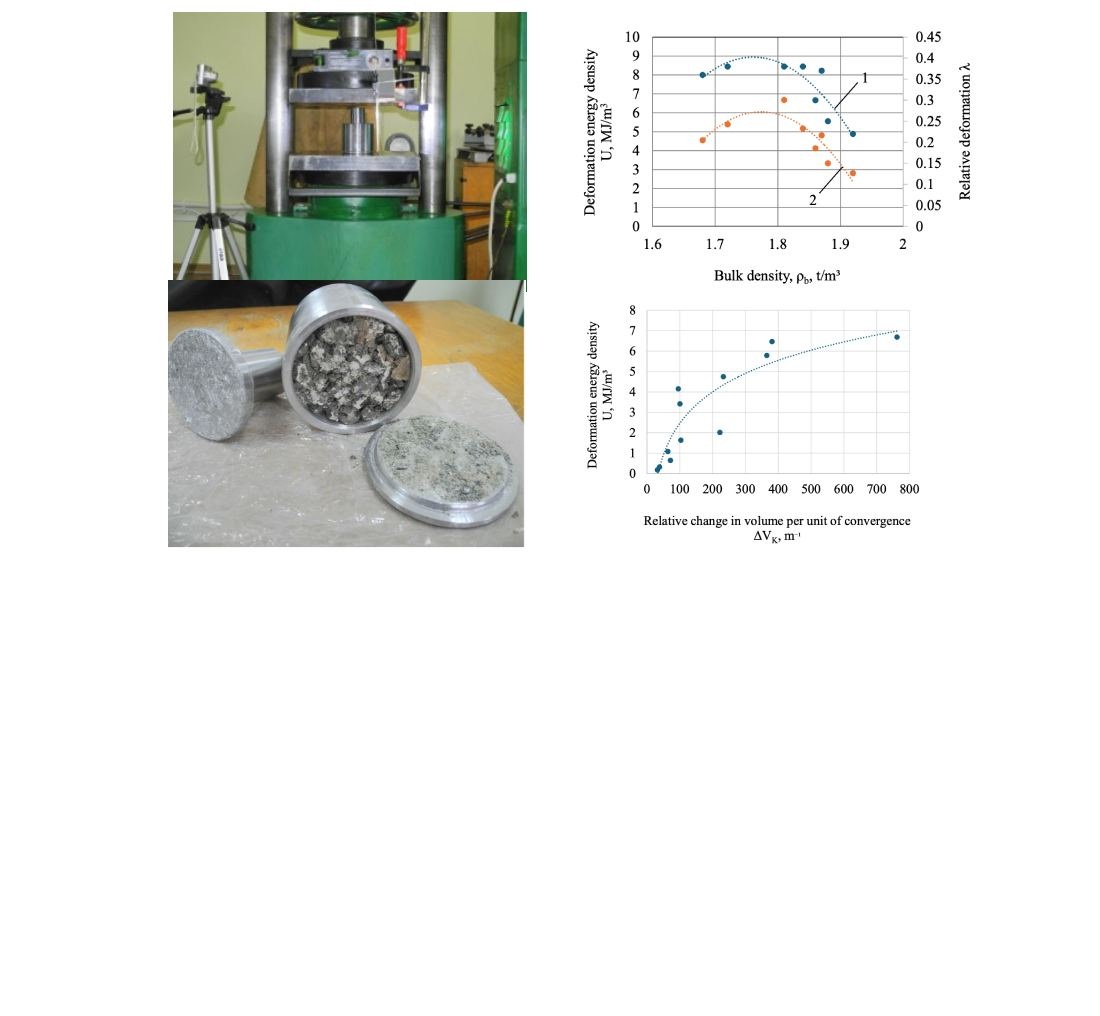

Deformation processes were studied on model materials made of crushed rock of various grain-size distributions and bulk densities. The material was subjected to compression testing, which simulated the complete backfilling of the gob area. It was shown that the energy characteristics of deformation and compaction of crushed rock determine the bearing capacity of backfills. The deformation energy density was determined by the grain-size distribution of the crushed rock with a polyfractional composition. The maximum values of the specific potential deformation energy were recorded during compression of crushed rock with a coefficient of uniformity Сu = 5.99, which has a stiffness 7–13% higher than that of polyfractional materials with Сu < 4, which ensures the bearing capacity of the backfill mass. It was established that with an increase in the compaction coefficient of the backfill material, the relative volume change per unit of convergence, ΔVK (m⁻1), occurs according to a hyperbolic relationship, allowing the prediction of the ultimate compaction of the backfill material.

The stability of gob-side retained entries can be ensured by complete gob backfilling. The expected settlement of the backfill material determines the nature of the limitation of lateral rock movements in the gob area, the bearing capacity of the artificial massif, and depends on the grain-size distribution of the crushed rock

References

- Feng, X., Zhang, N., Gong, L., Xue, F., Zheng, X. (2015). Application of a Backfilling Method in Coal Mining to Realise an Ecologically Sensitive “Black Gold” Industry. Energies, 8 (5), 3628–3639. https://doi.org/10.3390/en8053628

- Kuzyk, I. (2012). Vplyv porodnykh vidvaliv shakht na komponenty dovkillia ta vyznachennia mozhlyvostei shchodo yoho zmenshennia. Ekolohiya i pryrodokorystuvannia, 15, 23–37.

- Maydukov, G. (2007). Kompleksnoe ispol'zovanie ugol'nykh mestorozhdeniy Donbassa kak osnova ekologicheskoy bezopasnosti i energosberezheniya v regione. Ekonomichnyi visnyk Donbasu, 4 (10), 12–19.

- Zhou, N., Zhang, J., Yan, H., Li, M. (2017). Deformation Behavior of Hard Roofs in Solid Backfill Coal Mining Using Physical Models. Energies, 10 (4), 557. https://doi.org/10.3390/en10040557

- Zhang, J., Zhou, N., Huang, Y., Zhang, Q. (2011). Impact law of the bulk ratio of backfilling body to overlying strata movement in fully mechanized backfilling mining. Journal of Mining Science, 47 (1), 73–84. https://doi.org/10.1134/s1062739147010096

- Smoliński, A., Malashkevych, D., Petlovanyi, M., Rysbekov, K., Lozynskyi, V., Sai, K. (2022). Research into Impact of Leaving Waste Rocks in the Mined-Out Space on the Geomechanical State of the Rock Mass Surrounding the Longwall Face. Energies, 15 (24), 9522. https://doi.org/10.3390/en15249522

- Podkopaiev, S., Gogo, V., Yefremov, I., Kipko, O., Iordanov, I., Simonova, Y. (2019). Phenomena of stability of the coal seam roof with a yielding support. Mining of Mineral Deposits, 13 (4), 28–41. https://doi.org/10.33271/mining13.04.028

- Karfakis, M. G., Bowman, C. H., Topuz, E. (1996). Characterization of coal-mine refuse as backfilling material. Geotechnical and Geological Engineering, 14 (2), 129–150. https://doi.org/10.1007/bf00430273

- Li, M., Zhang, J. X., Miao, X. X. (2014). Experimental investigation on compaction properties of solid backfill materials. Mining Technology, 123 (4), 193–198. https://doi.org/10.1179/1743286314y.0000000066

- Jiang, H., Cao, Y., Huang, P., Fang, K., Li, B. (2015). Characterisation of coal-mine waste in solid backfill mining in China. Mining Technology, 124 (1), 56–63. https://doi.org/10.1179/1743286315y.0000000002

- Petlovanyi, M., Malashkevych, D., Sai, K., Bulat, I., Popovych, V. (2021). Granulometric composition research of mine rocks as a material for backfilling the mined-out area in coal mines. Mining of Mineral Deposits, 15 (4), 122–129. https://doi.org/10.33271/mining15.04.122

- Bachurin, L. L., Iordanov, I. V., Simonova, Yu. I., Korol, A. V., Podkopaiev, Ye. S., Kaiun, O. P. (2020). Experimental studies of the deformation characteristics of filling massifs. Technical Engineering, 2 (86), 136–149. https://doi.org/10.26642/ten-2020-2(86)-136-149

- Pappas, D. M., Mark, C. (1993). Behavior of simulated longwall gob material. Report of Investigations. Available at: https://www.researchgate.net/profile/Deno-Pappas-2/publication/255084112_Behavior_of_simulated_longwall_gob_material_Report_of_Investigations1993/links/58c6081da6fdcce648e8ba4d/Behavior-of-simulated-longwall-gob-material-Report-of-Investigations-1993.pdf

- Salamon, M. D. G. (2020). Mechanism of caving in longwall coal mining. Rock Mechanics Contributions and Challenges: Proceedings of the 31st U.S. Symposium, 161–168. https://doi.org/10.1201/9781003078944-26

- Zhang, J. X., Huang, Y. L., Li, M., Zhang, Q., Liu, Z. (2014). Test on mechanical properties of solid backfill materials. Materials Research Innovations, 18, S2-960-S2-965. https://doi.org/10.1179/1432891714z.000000000510

- Zhang, Q., Zhang, J., Han, X., Ju, F., Tai, Y., Li, M. (2016). Theoretical research on mass ratio in solid backfill coal mining. Environmental Earth Sciences, 75 (7). https://doi.org/10.1007/s12665-015-5234-5

- Malashkevych, D. S. (2021). Rozrobka tekhnolohichnykh skhem selektyvnoho vidpratsiuvannia plastiv iz zalyshenniam porody u vyroblenomu prostori (na prykladi shakht Zakhidnoho Donbasu). Dnipro: LizunovPres, 189.

- Tkachuk, O., Chepiga, D., Bachurin, L., Podkopaiev, S., Bachurina, Y., Podkopayev, Y. et al. (2025). Assessment of deformation processes in backfill masses using crushed rock models. Technology Audit and Production Reserves, 4 (1 (84)), 50–57. https://doi.org/10.15587/2706-5448.2025.333869

- Glushikhin, F. P., Zlotnikov, M. S. (1978). Ekvivalentnye materialy dlya modelirovaniya gornogo davleniya. Moscow: TSNIEIugol', 34.

- Sadd, M. H. (2009). Elasticity. Academic Press. https://doi.org/10.1016/b978-0-12-374446-3.x0001-6

- Chepiga, D., Polii, D., Podkopaiev, S., Bachurin, L., Bielikov, A., Slashchov, I. et al. (2025). Evaluating the stiffness of a cast strip for protecting a preparatory mine working. Eastern-European Journal of Enterprise Technologies, 2 (1 (134)), 40–50. https://doi.org/10.15587/1729-4061.2025.324548

- DSTU B V.2.1-4-96. Osnovy ta pidvalyny budynkiv i sporud. Grunty. Metody laboratornoho vyznachennia kharakterystyk mitsnosti i deformovanosti. Kyiv. Available at: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=4905

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Daria Chepiga, Oleksandr Tkachuk, Leonid Bachurin, Yaroslava Bachurina, Yevgen Podkopayev, Anatolii Bielikov, Olena Visyn, Serhii Podkopaiev, Larysa Bondarchuk, Igor Androshchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.