Establishing patterns in the formation of biocomposites for thermal insulation of building structures

DOI:

https://doi.org/10.15587/1729-4061.2025.337401Keywords:

biocomposites, thermal insulation products, thermophysical properties, fire resistance, foam coke layer, coating swellingAbstract

This study's object is the process that forms fire-resistant biocomposites based on wood chips and inorganic and organic binders. The task addressed relates to the need to enable resistance to high-temperature flames. This is important for the technology of application and production of environmentally friendly biocomposites obtained from natural and renewable sources for construction.

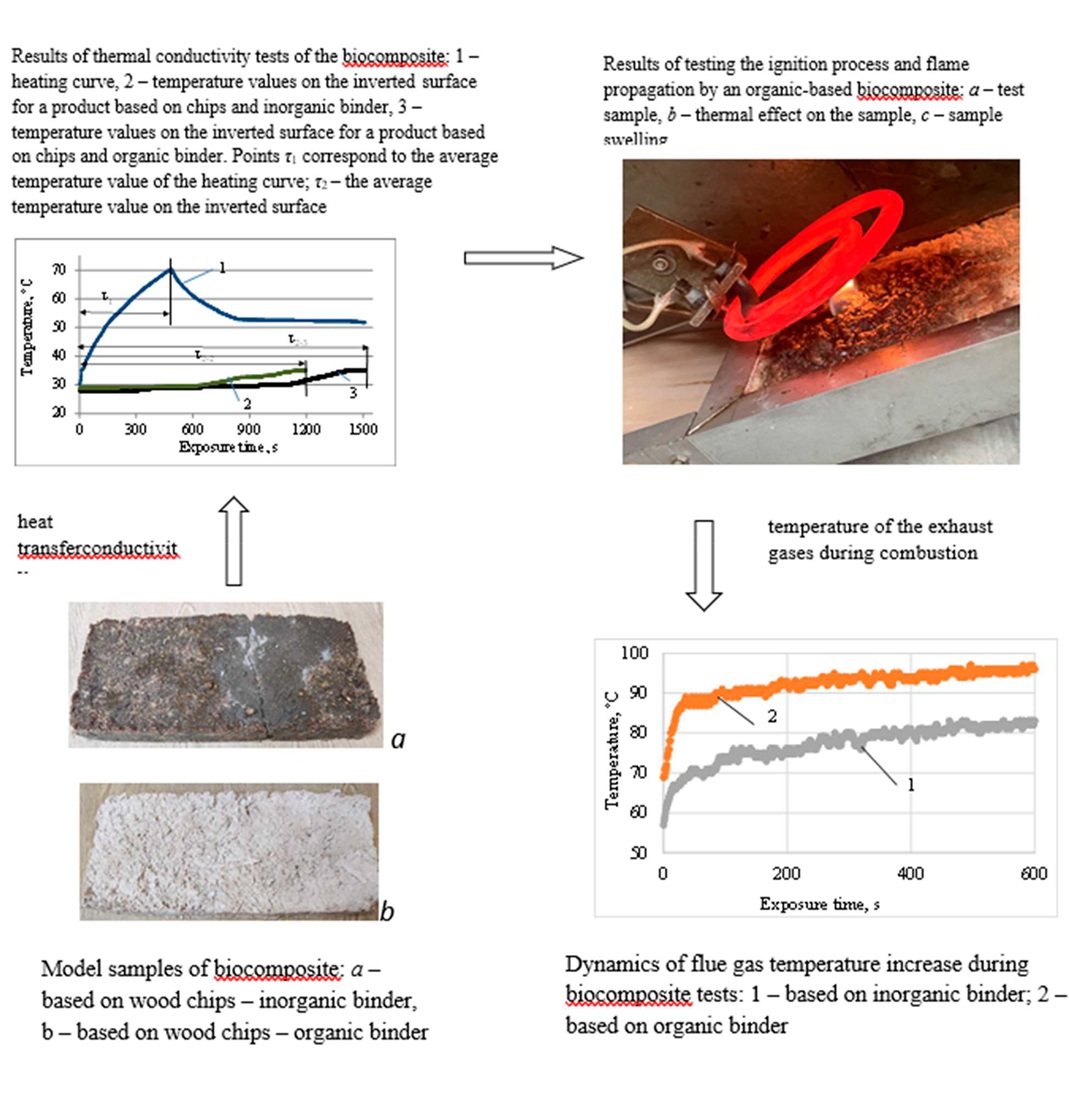

It has been proven that when determining the thermal insulation properties of the resulting materials, the temperature conductivity of the biocomposite on an inorganic basis was 0.22·106 m2/s while the thermal conductivity of the sample did not exceed 0.132 W/(m∙K). In contrast, for an organic-based biocomposite, the thermal conductivity value decreases by more than 6 times, the temperature conductivity – by more than 7 times.

In addition, the heat capacity of the product based on inorganic binder corresponds to a value within 1.6 kJ/(kg∙K), and the heat capacity value for the product made of biocomposite based on organic basis was 7.66 kJ/(kg∙K), respectively.

When a radiation panel was applied to the biocomposite samples, the temperature of the gaseous combustion products increased to 96°C, and the sample did not ignite. A study of the compressive strength of biocomposites showed that the product formed on the basis of wood and inorganic binder is more fragile; the tensile strength corresponds to an average value of 0.5 MPa. In contrast, for the biocomposite formed on the basis of chips and organic binder, the average tensile strength is 2.4 MPa, which is more than 4.7 times higher than the product based on inorganic basis.

The practical importance relates to the fact that the results were taken into account when developing a thermal insulation product for construction. Thus, there are grounds for the production of biocomposites for thermal insulation

References

- Anannya, F. R., Mahmud, Md. A. (2019). Developments in Flame-Retardant Bio-composite Material Production. Advances in Civil Engineering Materials, 8 (1), 9–22. https://doi.org/10.1520/acem20180025

- Rashid, M., Chetehouna, K., Lemée, L., Roudaut, C., Gascoin, N. (2022). Study of flame retardancy effect on the thermal degradation of a new green biocomposite and estimation of lower flammability limits of the gaseous emissions. Journal of Thermal Analysis and Calorimetry, 147 (17), 9367–9382. https://doi.org/10.1007/s10973-022-11233-7

- Podkościelna, B., Wnuczek, K., Goliszek, M., Klepka, T., Dziuba, K. (2020). Flammability Tests and Investigations of Properties of Lignin-Containing Polymer Composites Based on Acrylates. Molecules, 25 (24), 5947. https://doi.org/10.3390/molecules25245947

- Giancaspro, J., Papakonstantinou, C., Balaguru, P. (2009). Mechanical behavior of fire-resistant biocomposite. Composites Part B: Engineering, 40 (3), 206–211. https://doi.org/10.1016/j.compositesb.2008.11.008

- Feng, J., Lu, Y., Xie, H., Zhang, Y., Huo, S., Liu, X. et al. (2023). Atom-economic synthesis of an oligomeric P/N-containing fire retardant towards fire-retarding and mechanically robust polylactide biocomposites. Journal of Materials Science & Technology, 160, 86–95. https://doi.org/10.1016/j.jmst.2023.04.003

- Prabhakar, M. N., Cabo, M. C., Yu, R., Gebrekrstos Weldemhret, T., Dong Woo, L., Jung-il, S. (2024). Surface flame retardancy of clay mineral powder infused onto the top of the layer of vinyl ester/bamboo composites through a modified VARTM process. Polymer Testing, 132, 108367. https://doi.org/10.1016/j.polymertesting.2024.108367

- Rajeshkumar, L., Kumar, P. S., Boonyasopon, P., Rangappa, S. M., Siengchin, S. (2024). Flame retardance behaviour and degradation of plant-based natural fiber composites – A comprehensive review. Construction and Building Materials, 432, 136552. https://doi.org/10.1016/j.conbuildmat.2024.136552

- Madyaratri, E., Ridho, M., Aristri, M., Lubis, M., Iswanto, A., Nawawi, D. et al. (2022). Recent Advances in the Development of Fire-Resistant Biocomposites – A Review. Polymers, 14 (3), 362. https://doi.org/10.3390/polym14030362

- Zambaldi, E., Magalhães, R. R., Dias, M. C., Mendes, L. M., Tonoli, G. H. D. (2022). Numerical simulation of poly(lactic acid) polymeric composites reinforced with nanofibrillated cellulose for industrial applications. Polymer Engineering & Science, 62 (12), 4043–4054. https://doi.org/10.1002/pen.26165

- Vitola, L., Gendelis, S., Sinka, M., Pundiene, I., Bajare, D. (2022). Assessment of Plant Origin By-Products as Lightweight Aggregates for Bio-Composite Bounded by Starch Binder. Energies, 15 (15), 5330. https://doi.org/10.3390/en15155330

- Moussa, T., Maalouf, C., Bliard, C., Abbes, B., Badouard, C., Lachi, M. et al. (2022). Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures. Materials, 15 (5), 1689. https://doi.org/10.3390/ma15051689

- Hegyi, A. (2017). Biocomposites Materials For Sustainable Construction. SGEM International Multidisciplinary Scientific GeoConference EXPO Proceedings. https://doi.org/10.5593/sgem2017/62/s26.004

- Liukko, S., Dimic-Misic, K., Janackovic, A., Gasik, M. (2025). Improving Mechanical and Thermal Properties of Cellulose Foam with Alumina Nanofibers. Polymers, 17 (8), 1043. https://doi.org/10.3390/polym17081043

- Zare, R., Hassan Pour, F., Bacchus, A., Fatehi, P. (2025). Lignin containing aerogel biocomposites. Biocomposites and the Circular Economy, 59–105. https://doi.org/10.1016/b978-0-443-23718-8.00004-1

- Ansari, K. H., Routroy, S., Samyal, R., Kaushik, S. (2025). Development and optimization of pearl millet waste biocomposite ceiling tiles: a waste management approach. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-025-08351-1

- Tsapko, Y., Zavialov, D., Bondarenko, O., Marchenco, N., Mazurchuk, S., Horbachova, O. (2019). Determination of thermal and physical characteristics of dead pine wood thermal insulation products. Eastern-European Journal of Enterprise Technologies, 4 (10 (100)), 37–43. https://doi.org/10.15587/1729-4061.2019.175346

- Tsapko, Y., Tsapko, А. (2018). Establishment of fire protective effectiveness of reed treated with an impregnating solution and coatings. Eastern-European Journal of Enterprise Technologies, 4 (10 (94)), 62–68. https://doi.org/10.15587/1729-4061.2018.141030

- ISO 13061-3:2014. Physical and mechanical properties of wood - Test methods for small clear wood specimens - Part 3: Determination of ultimate strength in static bending. Available at: https://cdn.standards.iteh.ai/samples/60065/5c53a08bc66943418d5a7d2c31e9869f/ISO-13061-3-2014.pdf

- Tsapko, Y., Kasianchuk, I., Likhnyovskyi, R., Tsapko, А., Kovalenko, V., Nizhnyk, V. et al. (2023). Determining thermal and physical characteristics of wood polymer material for pipeline thermal insulation. Eastern-European Journal of Enterprise Technologies, 5 (10 (125)), 63–72. https://doi.org/10.15587/1729-4061.2023.289341

- Horbachova, O., Tsapko, Y., Tsarenko, Y., Mazurchuk, S., Kasianchuk, I. (2023). Justification of the Wood Polymer Material Application Conditions. Journal of Engineering Sciences, 10 (2), C49–C55. https://doi.org/10.21272/jes.2023.10(2).c6

- Tsapko, Y., Tsapko, А., Bondarenko, O. (2020). Modeling the process of moisture diffusion by a flame-retardant coating for wood. Eastern-European Journal of Enterprise Technologies, 1 (10 (103)), 14–19. https://doi.org/10.15587/1729-4061.2020.192687

- Tsapko, Y. V., Tsapko, A., Bondarenko, O. P., Sukhanevych, M. V., Kobryn, M. V. (2019). Research of the process of spread of fire on beams of wood of fire-protected intumescent coatings. IOP Conference Series: Materials Science and Engineering, 708 (1), 012112. https://doi.org/10.1088/1757-899x/708/1/012112

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yuriy Tsapko, Аleksii Tsapko, Vasyl Lomaha, Pavlo Illiuchenko, Oksana Berdnyk, Ruslan Likhnyovskyi, Kseniia Bielikova, Nataliia Dyuzhilova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.