Development of an anti-surge protection system for gas pumping units based on hardware and software vibration monitoring tools

DOI:

https://doi.org/10.15587/1729-4061.2025.337736Keywords:

surge phenomenon, vibration monitoring, GPU automatic control system, extrapolation model, TIA Portal, anti-surge valveAbstract

This study’s object is the non-stationary process of gas flow stall in the compressor of a gas pumping unit (GPU), accompanied by surge oscillations. The task relates to the need for a comprehensive approach to the design and operation of anti-surge protection systems based on improved procedures, algorithms, and unified hardware and software solutions.

A procedure has been devised for predicting surge oscillations during the sequential operation of two compressor stations. Its distinctive feature is the processing of data on the dynamics of technological parameters of an actual facility under pre-surge and surge modes to construct a corrected extrapolation model. The method ensures an acceptable prediction error with a root mean square deviation of 10–15%.

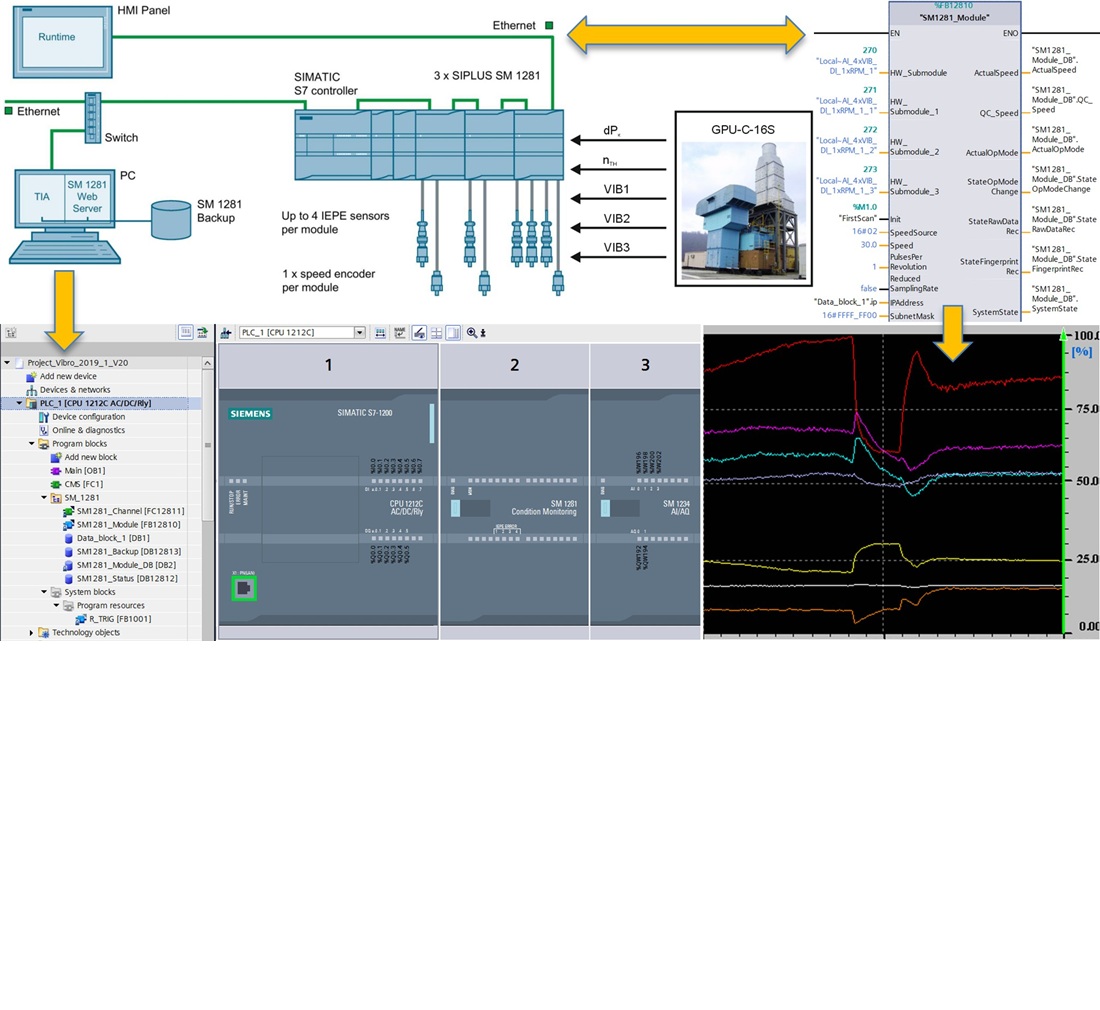

An anti-surge protection system for GPU with forecasting functionality has been designed, based on offset and vibration displacement parameters of the compressor’s rear bearing support in vertical and horizontal directions. Hardware and software solutions were implemented using a PLC S7-1200, SM 1281 vibration module, as well as CMS2000 VIB-SENSOR. The system enables monitoring of rear bearing support vibration displacement in the range from 0 to 80 μm, with an «optimal» operating point of 40 μm. The permissible monitoring distance to the control object is up to 30 m without loss of vibration signal quality.

A dispatcher interface has been designed with functions for visualization, archiving, alarm signaling about technological parameters, and calculating the predicted moment of GPU surge onset.

A subsystem for controlling the station’s anti-surge valve has been designed, with status indication, based on the developed FB1 «Program» algorithm with the vibration state parameters at the facility

References

- Alsuwian, T., Amin, A. A., Iqbal, M. S., Maqsood, M. T. (2023). A review of anti-surge control systems of compressors and advanced fault-tolerant control techniques for integration perspective. Heliyon, 9 (9), e19557. https://doi.org/10.1016/j.heliyon.2023.e19557

- Bentaleb, T., Cacitti, A., De Franciscis, S., Garulli, A. (2015). Model Predictive Control for pressure regulation and surge prevention in centrifugal compressors. 2015 European Control Conference (ECC), 3346–3351. https://doi.org/10.1109/ecc.2015.7331051

- Mirsky, S., Jacobson, W., Tiscornia, D., McWhirter, J., Zaghloul, M. (2012). Development and design of antisurge and performance control systems for centrifugal compressors. Proceedings of the Forty-Second Turbomachinery Symposium. Available at: https://core.ac.uk/download/pdf/147258448.pdf

- Daniarta, S., Wardana, A. N. I., Rosita, W. (2016). Performance evaluation of compressor anti-surge control based on model predictive in ammonia plant. 2016 International Seminar on Application for Technology of Information and Communication (ISemantic), 75–79. https://doi.org/10.1109/isemantic.2016.7873813

- Chetate, B., Zamoum, R., Fegriche, A., Boumdin, M. (2013). PID and Novel Approach of PI Fuzzy Logic Controllers for Active Surge in Centrifugal Compressor. Arabian Journal for Science and Engineering, 38 (6), 1405–1414. https://doi.org/10.1007/s13369-013-0601-6

- Kolnsberg, A. (1979). Reasons for Centrifugal Compressor Surging and Surge Control. Journal of Engineering for Power, 101 (1), 79–86. https://doi.org/10.1115/1.3446465

- Hou, Y., Wang, Y., Pan, Y., He, W., Huang, W., Wu, P., Wu, D. (2023). Vibration-based incipient surge detection and diagnosis of the centrifugal compressor using adaptive feature fusion and sparse ensemble learning approach. Advanced Engineering Informatics, 56, 101947. https://doi.org/10.1016/j.aei.2023.101947

- Dietel, F., Schulze, R., Richter, H., Jakel, J. (2012). Fault detection in rotating machinery using spectral modeling. 2012 9th France-Japan & 7th Europe-Asia Congress on Mechatronics (MECATRONICS) / 13th Int’l Workshop on Research and Education in Mechatronics (REM), 353–357. https://doi.org/10.1109/mecatronics.2012.6451032

- Niccolini Marmont Du Haut Champ, C. A., Silvestri, P., Ferrari, M. L., Massardo, A. F. (2020). Signal Processing Techniques to Detect Centrifugal Compressors Instabilities in Large Volume Power Plants. Journal of Engineering for Gas Turbines and Power, 142 (12). https://doi.org/10.1115/1.4048910

- Sandoval, O. R., Machado, L. H. J., Hanriot, V. M., Troysi, F., Faria, M. T. C. (2022). Acoustic and vibration analysis of a turbocharger centrifugal compressor failure. Engineering Failure Analysis, 139, 106447. https://doi.org/10.1016/j.engfailanal.2022.106447

- Liśkiewicz, G., Kulak, M., Sobczak, K., Stickland, M. (2020). Numerical Model of a Deep Surge Cycle in Low-Speed Centrifugal Compressor. Journal of Turbomachinery, 142 (12). https://doi.org/10.1115/1.4048328

- Hurinenko, V. M., Ivanyshyn, V. P. (2012). Pidvyshchennia efektyvnosti ekspluatatsiyi kompresornoi stantsiyi KS «Dolyna». Naukovi visti: Halytska akademiya, 2 (22), 29–36.

- Hrudz, Ya. V. (2012). Prohnozuvannia tekhnichnoho stanu hazoperekachuvalnykh ahrehativ. Rozvidka ta rozrobka naftovykh i hazovykh rodovyshch, 4 (45). Available at: http://nbuv.gov.ua/UJRN/rrngr_2012_4_19

- Bliaut, Yu. Ye. (2013). Avtomatychna identyfikatsiya pompazhnykh kharakterystyk hazoperekachuvalnykh ahrehativ z hazoturbinnym pryvodom dlia efektyvnoho rehuliuvannia. Ivano-Frankivsk: Ivano-Frankivskyi nats. tekh. un-t nafty i hazu, 20. Available at: https://www.library.nung.edu.ua/katalog-avtoreferatiiv-disertatsiii-zakhishchenikh-v-iifntung-z-fondu-ntb.html

- Zamikhovska, O. L., Zamikhovskyi, L. M., Ivaniuk, N. I. (2021). Rozrobka protsedury prohnozuvannia vynyknennia pompazhnykh yavyshch pry poslidovniy roboti dvokh kompresornykh stantsiy. X Naukova konferentsiia «NAUKOVI PIDSUMKY 2021 ROKU». Kharkiv, 21. Available at: https://entc.com.ua/download/%D0%97%D0%B1%D1%96%D1%80%D0%BA%D0%B0_%D0%BD%D0%B0%D1%83%D0%BA%D0%BE%D0%B2%D0%B8%D1%85_%D0%BF%D1%80%D0%B0%D1%86%D1%8C_%D0%9D%D0%B0%D1%83%D0%BA%D0%BE%D0%B2%D1%96_%D0%BF%D1%96%D0%B4%D1%81%D1%83%D0%BC%D0%BA%D0%B8_2021.pdf

- SIMATIC STEP 7 Basic/Professional V17 and SIMATIC WinCC V17. Available at: https://support.industry.siemens.com/cs/document/109798671/simatic-step-7-basic-professional-v17-and-simatic-wincc-v17?dti=0&lc=en-UA

- Zamikhovskyi, L., Nykolaychuk, M., Levytskyi, I. (2024). Organizing the automated system of dispatch control over pump units at water pumping stations. Eastern-European Journal of Enterprise Technologies, 5 (2 (131)), 61–75. https://doi.org/10.15587/1729-4061.2024.313531

- Adasovskyi, B. I., Zamikhovskyi, L. M. (2014). Diahnostuvannia system. Ivano-Frankivsk: IFNTUNH, 116.

- Zamikhovskyi, L. М., Zamikhovska, О. L., Ivaniuk, N. І., Pavlyk, V. V. (2020). Improvement of the automatic control system of gas-pumping units taking into account their technical condition. Oil and Gas Power Engineering, 2 (34), 84–95. https://doi.org/10.31471/1993-9868-2020-2(34)-84-95

- PID Control with PID_Compact for SIMATIC S7-1200/S7-1500. Available at: https://support.industry.siemens.com/cs/document/100746401/pid-control-with-pid_compact-for-simatic-s7-1200-s7-1500?dti=0&lc=en-US

- Condition Monitoring Systems. SIPLUS CMS1200. SM 1281 Condition Monitoring. Operating Instructions. Available at: https://cache.industry.siemens.com/dl/files/490/109481490/att_885698/v1/cms1200_sm1281_operating_manual_en-US_en-US.pdf

- Zamikhovskiy, L., Ivanuyk, N. (2017). Control system of operation of gas pumping unit taking into account its technical condition. PEN Conference Systems, Innovative Ideas in Science.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Leonid Zamikhovskyi, Olena Zamikhovska, Nataliia Ivanyuk, Oleksandra Mirzoieva, Mykola Nykolaychuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.