Establishing patterns of structural-phase transformations when processing technogenic waste of high-speed steels by carbon thermal reduction

DOI:

https://doi.org/10.15587/1729-4061.2025.337916Keywords:

scale, high-speed steel, oxide technogenic waste, carbon thermal reduction, structural-phase transformationsAbstract

The object of this study is structural and phase transformations during the reduction of high-speed steel scale with carbon to obtain a resource-saving alloying additive. The task addressed is the loss of high-value elements when obtaining and using alloying material from man-made raw materials. Solving the problem is associated with determining technological indicators to enable the reduction of losses of the corresponding elements.

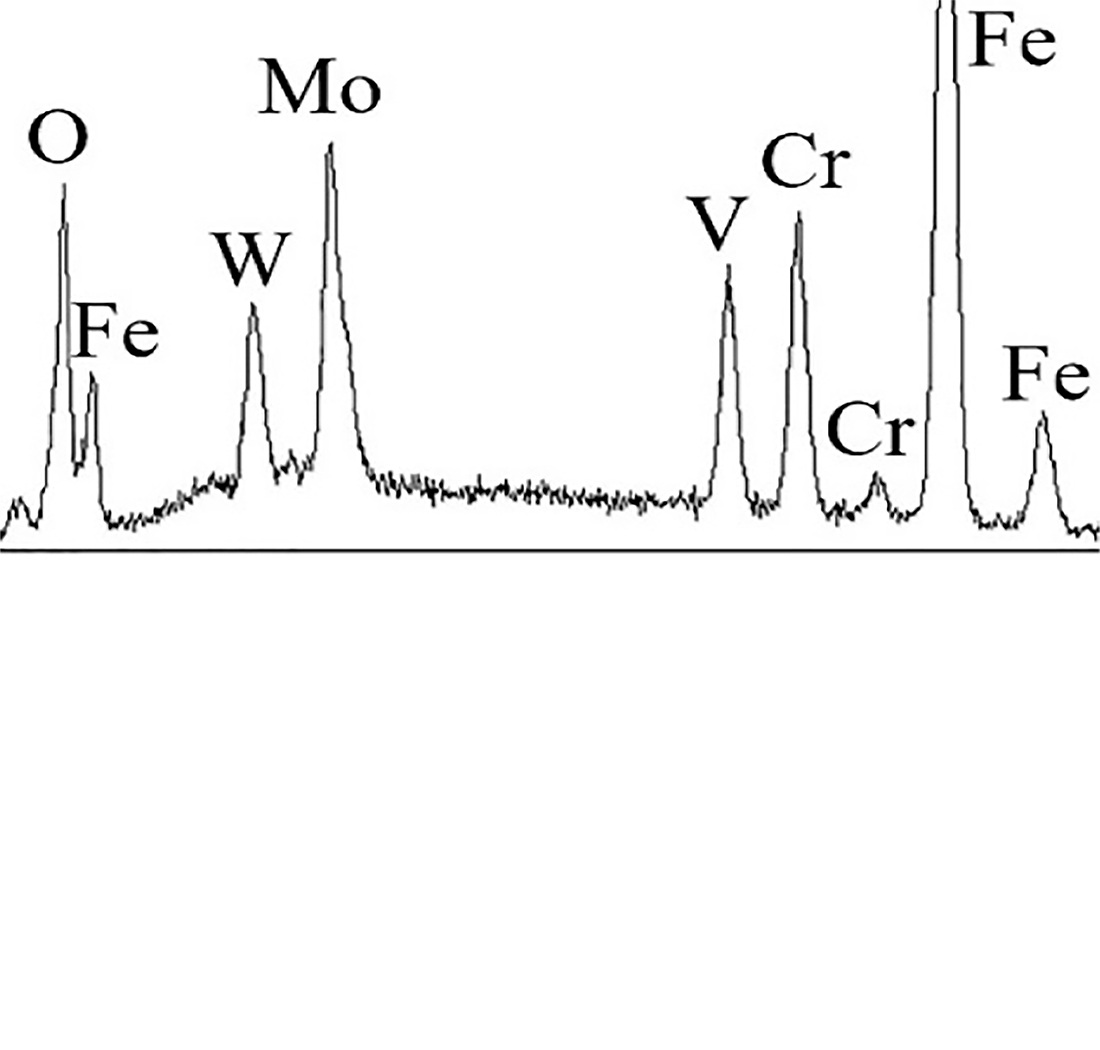

It has been determined that the phase composition of the scale had the manifestation of FeO, Fe2O3, Fe3O4, FeWO4, MoO2, FeW3C, W2C and Mo2C. In the reduction products, a solid solution of alloying elements and carbon in α-Fe, residual oxides Fe2O3, Fe3O4 and carbides FeW3C, WC, Mo2C, Cr7C3, Cr3C2, Cr23C6, VC was found.

The disordered structure of the scale with particles of irregular shape after reduction was characterized by the presence of formations of polyhedral and rounded shapes with different contents of alloying elements. Residual oxygen was within 5.78–7.14% by weight. It was established that achieving a reduction degree of 79% is sufficient since the residual carbon in carbides provides an increased reducing ability during the further reduction of the oxide component in the liquid metal during alloying.

The porous structure causes faster dissolution compared to standard ferroalloys, which reduces the resources consumed by reducing the melting time. No phases with an increased tendency to sublimation were found in the obtained alloying additive. That is, there is no need to create additional conditions that prevent the loss of alloying elements during evaporation with the gas phase, which ensures an increase in the degree of extraction of the corresponding elements.

The properties of the obtained alloying additive allow it to be used in smelting in an electric arc furnace as a replacement for part of standard ferroalloys

References

- Petryshchev, A., Milko, D., Borysov, V., Tsymbal, B., Hevko, I., Borysova, S., Semenchuk, A. (2019). Studying the physicalchemical transformations at resourcesaving reduction melting of chrome–nickelcontaining metallurgical waste. Eastern-European Journal of Enterprise Technologies, 2 (12 (98)), 59–64. https://doi.org/10.15587/1729-4061.2019.160755

- Sekiguchi, N. (2017). Trade specialisation patterns in major steelmaking economies: the role of advanced economies and the implications for rapid growth in emerging market and developing economies in the global steel market. Mineral Economics, 30 (3), 207–227. https://doi.org/10.1007/s13563-017-0110-2

- Çevik, E. (2021). Doğrudan İndirgeme Tekniğiyle Yüksek Demirli Sıcak Haddehane Tufalinden Demirin Geri Kazanımı. Düzce Üniversitesi Bilim ve Teknoloji Dergisi, 9 (2), 581–590. https://doi.org/10.29130/dubited.841486

- Grigor’ev, S. M., Petrishchev, A. S. (2012). Assessing the phase and structural features of the scale on P6M5Φ3 and P12M3K5Φ2 steel. Steel in Translation, 42 (3), 272–275. https://doi.org/10.3103/s0967091212030059

- Grigor'ev, S. M., Karpunina, M. S., Moskalenko, A. S. (1999). Razrabotka resursosberegayuschey tekhnologii polucheniya khromsoderzhaschikh briketov dlya legirovaniya stali. Stal', 9, 32–35.

- Poliakov, A., Volokh, V., Andreev, A., Rebenko, V., Kurlov, V., Yamshinskij, M. et al. (2024). Identifying patterns in the structural-phase transformations when processing oxide doped waste with the use of carbon reducer. Eastern-European Journal of Enterprise Technologies, 5 (12 (131)), 25–30. https://doi.org/10.15587/1729-4061.2024.313449

- Volokh, V., Poliakov, A., Rebenko, V., Andreev, A., Yamshinskij, M., Lukianenko, I. et al. (2023). Identifying the features of structural and phase transformations during the processing of oxide waste from the production of high-speed steel. Eastern-European Journal of Enterprise Technologies, 5 (12 (125)), 17–22. https://doi.org/10.15587/1729-4061.2023.288506

- Bagdavadze D. I., Dzhanelidze I. S., Ukleba K. Z., Chumbadze M. T., Tsikaridze Z. N., Razmadze M. S. (2008). Termodinamicheskiy analiz karbotermicheskogo vosstanovleniya Cr2O3 i smesi oksidov Cr2O3-SiO2, Cr2O3-SiO2-FeO, MnO-SiO2-Cr2O3. Izvestiya Natsional'noy Akademii Nauk Gruzii, 35 (2), 212–218.

- Petryshchev, A. S., Hryhoriev, S. M. (2009). Deiaki termodynamichni zakonomirnosti vuhletsevotermichnoho vidnovlennia vanadiyvmisnoi metalooksydnoi syrovyny. Novi materialy i tekhnolohiyi v metalurhiyi ta mashynobuduvanni, 2, 115–120.

- Smirnov, A., Petryshchev, A., Bilko, T., Andreev, A., Semenko, A., Skorobagatko, Y. (2023). Development of the Recycling of Alloyed Metallurgical Waste: Features of Phase and Structural Transformations. Minerals, 13 (9), 1171. https://doi.org/10.3390/min13091171

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Victor Rebenko, Ivan Lukianenko, Vadym Volokh, Andrey Andreev, Anatolii Poliakov, Mykhail Yamshinskij, Dmytro Zhuravel, Dmytro Ivanchenko, Iryna Kovalenko, Yevhen Chaplyhin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.