Construction of a simulation model of the system "striker-tool-processed medium"

DOI:

https://doi.org/10.15587/1729-4061.2025.341450Keywords:

Ansys Mechanical, impact device, co-impact time, model identification, energy characteristicsAbstract

This study investigates the process of impulse interaction between the elements of an impact device and the processed medium (PM). The task addressed is to combine simulation and mathematical modeling of the process.

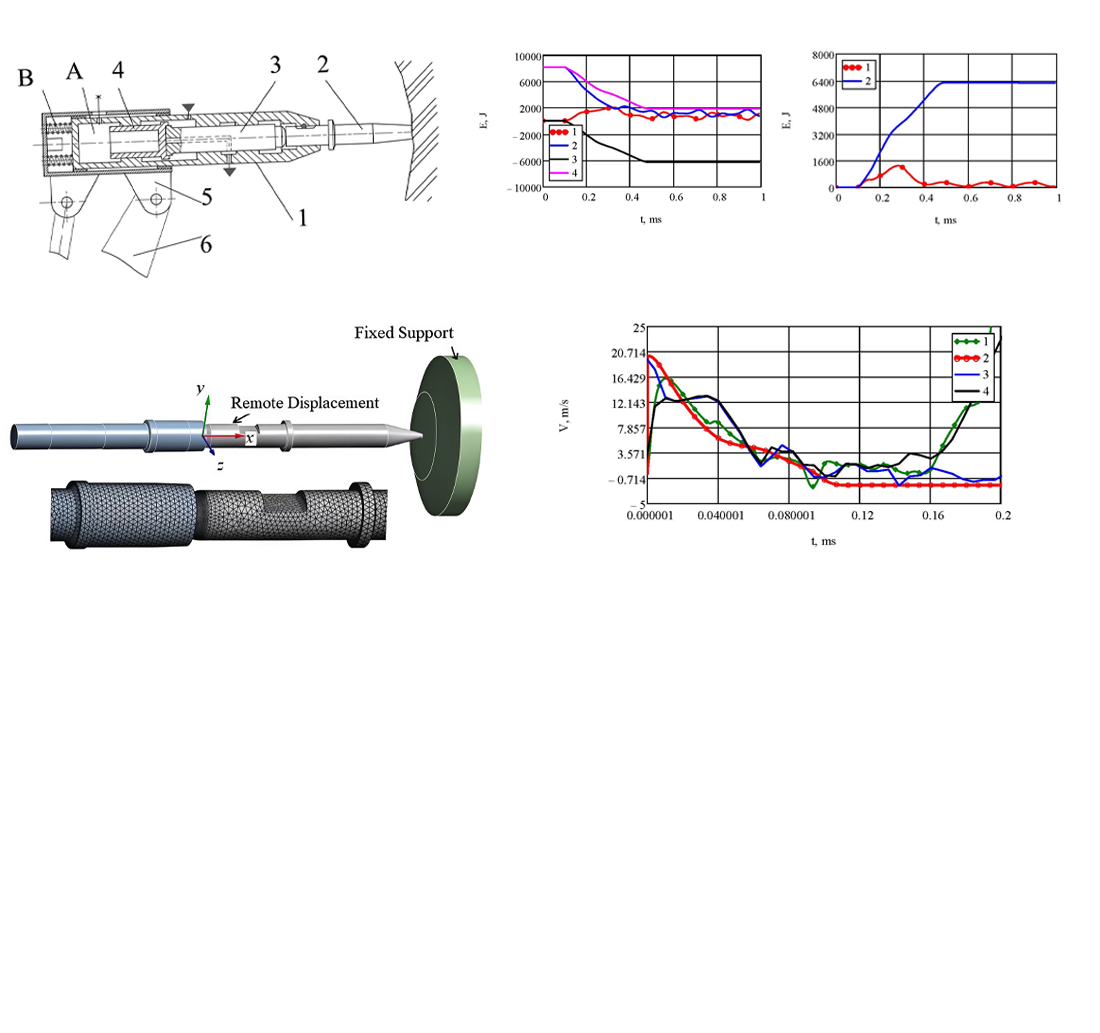

A simulation model of the striker has been constructed using the Ansys programming system. The basic elements of the striker were built in a geometric shape close to cylindrical; a PM simulator was developed in the Design Modeler module. The degrees of freedom of the elements, their physical properties and external factors were adopted in accordance with the structural scheme and operating modes of the striker.

Adequacy of the simulation model was assessed by comparison with discrete and discrete-continuous models. The finite difference method was used to solve the system of differential equations under given initial and boundary conditions. The comparison was carried out by the parameters of impact interaction: co-impact time, vibrations of the contact and impact ends of the tool. Strikers and tools of different sizes with flat contact ends were considered. The impact time was determined by the difference in speeds and displacements of the contact ends of the striker and the tool; it is 0.1–0.5 ms. In this case, the striker speed varied in the range of 3–20 m/s. High-frequency oscillations of the tool ends amounted to 3000–6000 Hz and were determined by the dimensions of the striker and the tool. The discrepancy of the parameters relative to the Ansys system did not exceed 10%.

The simulation model has made it possible to evaluate the energy transformation in the “striker-tool-processed medium” system. The coefficient of energy transfer to PM from the tool is 0.55–0.65; from the striker to the tool – 0.75–0.8.

The results lay the foundation for applying the simulation model to conduct numerical experiments involving elements of a striking device of complex geometric shape. The simulation model and discrete-continuous models could be used to select rational parameters when designing striking devices

References

- GoldsmithW. (1960). Impact. The theory and physical behaviour of collidingsolids. London: Edvard Arnold LTD, 393. Available at: https://ia601507.us.archive.org/33/items/in.ernet.dli.2015.133946/2015.133946.Impact-The-Theory-And-Physical-Behaviour-Of-Colliding-Solids.pdf

- Batako, A. D., Babitsky, V. I., Halliwell, N. A. (2004). Modelling of vibro-impact penetration of self-exciting percussive-rotary drill bit. Journal of Sound and Vibration, 271 (1-2), 209–225. https://doi.org/10.1016/s0022-460x(03)00642-4

- Batako, A. D., Babitsky, V. I., Halliwell, N. A. (2003). A self-excited system for percussive-rotary drilling. Journal of Sound and Vibration, 259 (1), 97–118. https://doi.org/10.1006/jsvi.2002.5158

- Yu Neyman, V., Markov, A. V. (2018). Linear electromagnetic drive of impact machines with retaining striker. IOP Conference Series: Earth and Environmental Science, 194, 062023. https://doi.org/10.1088/1755-1315/194/6/062023

- Yang, G., Fang, J. (2012). Structure Parameters Optimization Analysis of Hydraulic Hammer System. Modern Mechanical Engineering, 2 (4), 137–142. https://doi.org/10.4236/mme.2012.24018

- Slidenko, V., Slidenko, O., Marchuk, L., But, V. (2023). Development of a discreet-continuous mathematical model of a percussion device with parameters of influence on the characteristics of an impact pulse. Eastern-European Journal of Enterprise Technologies, 5 (7 (125)), 70–79. https://doi.org/10.15587/1729-4061.2023.290029

- Slidenko, V., Slidenko, O., Listovschik, L., Novykov, A., But, V. (2025). Construction of a mathematical model of an impact device with a two-element striker. Eastern-European Journal of Enterprise Technologies, 1 (7 (133)), 38–49. https://doi.org/10.15587/1729-4061.2025.322728

- Zhukov, I. A., Molchanov, V. V. (2014). Rational Designing Two-Stage Anvil Block of Impact Mechanisms. Advanced Materials Research, 1040, 699–702. https://doi.org/10.4028/www.scientific.net/amr.1040.699

- Zhukov, I. A., Dvornikov, L. T., Nikitenko, S. M. (2016). About creation of machines for rock destruction with formation of apertures of various cross-sections. IOP Conference Series: Materials Science and Engineering, 124, 012171. https://doi.org/10.1088/1757-899x/124/1/012171

- Zhukov, I., Repin, A., Timofeev, E. (2018). Automated calculation and analysis of impacts generated in mining machine by anvil blocks of complex geometry. IOP Conference Series: Earth and Environmental Science, 134, 012071. https://doi.org/10.1088/1755-1315/134/1/012071

- Samarskii, A. (2001). The Theory of Difference Schemes. New York: CRC Press, 786. https://doi.org/10.1201/9780203908518

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Viktor Slidenko, Oleksandr Slidenko, Oksana Zamaraeva, Anton Novykov, Vladyslav Tkachenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.