Improving the process characteristics of cutting fibrous composite materials

DOI:

https://doi.org/10.15587/1729-4061.2025.341455Keywords:

cutting characteristics, composite materials, machining, elastic properties, composite deformationAbstract

This study explores the process of cutting fibrous polymer composite materials. The main reason for limiting the use of polymer composites is the deterioration of their performance properties after mechanical processing because of destruction of the surface layer.

It is high time substantiated recommendations for the mechanical processing of fibrous polymer composites (FPCs) are provided. This could reduce the depth of destruction of an FPC surface layer to 20–50 μm and expand the area of functional application of these materials.

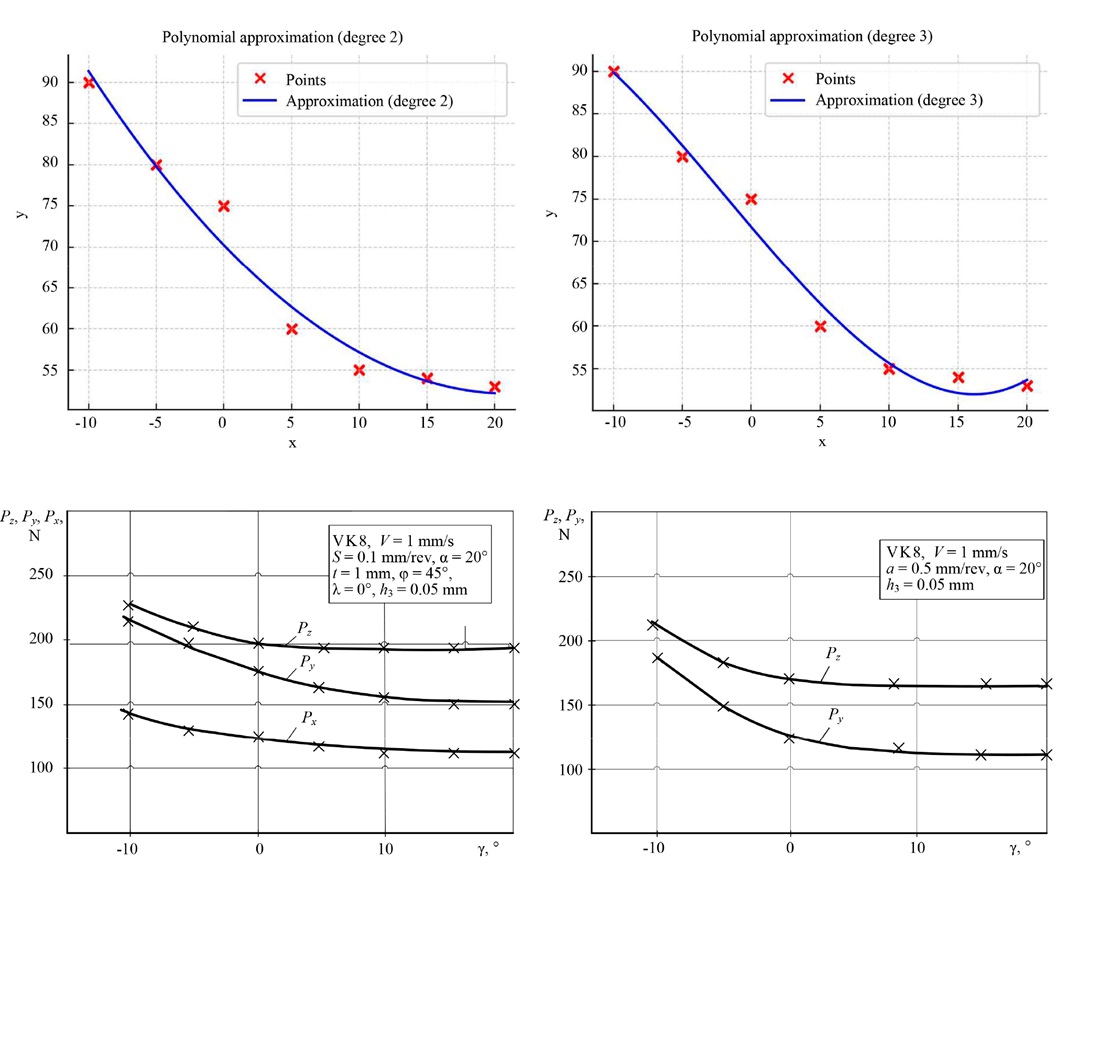

An experimental study on the influence of cutting modes and geometric parameters of the cutting part of the tools on the technological components of the cutting force has been conducted, which made it possible to establish that the greatest influence on the cutting force when processing fibrous composites is exerted by the values of the geometric characteristics of the tool. Reducing the energy consumption for cutting to the level of 1.5 kN∙m/s helps minimize the influence of mechanical, thermal, and chemical factors on the destruction of the composite.

FPCs have high elastic properties, which determines the features in the cutting process. As this leads to increased values of cutting forces on the rear surface, it is recommended to carry out processing by a sharpened tool at large values of the front γ and rear α angles of the blade.

Determining the cutting force makes it possible to correctly assign the geometric parameters of the tool and estimate the processing error. The specified machining modes make it possible to reduce the depth of the defective layer by 10 times (RZ ≤ 20 mm, KB ≤ 5%, N ≤ 1012 spin/gr, M ≤ 50 μm) and increase the stability of the cutting tool by two times.

The results could make it possible to improve the process of shaping articles from polymeric materials during production

References

- Sychev, Yu., Malitskiy, I. (2020). Improving the process of cutting polymer composites. Engineering, 25, 62–69. https://doi.org/10.32820/2079-1747-2020-25-62-69

- Tomashevskyi, O., Balytska, N. (2023). Features of milling composites. Analytical reviewanalytical review. Technical Engineering, 1 (91), 92–100. https://doi.org/10.26642/ten-2023-1(91)-92-100

- Liu, S. Q., Chen, Y., Fu, Y. C., Hu, A. D. (2016). Study on the Cutting Force and Machined Surface Quality of Milling AFRP. Materials Science Forum, 836-837, 155–160. https://doi.org/10.4028/www.scientific.net/msf.836-837.155

- Byelikov, S., Volchok, I., Mityaev, A., Pleskach, V., Savchenko, V. (2017). Composite materials in aircraft industry (review). Novi materialy i tekhnolohiyi v metalurhiyi ta mashynobuduvanni, 2, 32–40. Available at: http://nbuv.gov.ua/UJRN/Nmt_2017_2_8

- Khavin, G. L., Hou, Z. (2022). The orientation angle of reinforcing elements influence on tool wear intensity in processing polymer composites. Bulletin of the National Technical University “Kharkiv Polytechnic Institute” Series: Techniques in a Machine Industry, 1, 59–65. https://doi.org/10.20998/2079-x.2022.1(5).08

- Kolesnyk, V., Lysenko, B., Neshta, A., Zabara, M. (2022). Investigation of cutting parameters influence the roughness when drilling CFRP/ Ti alloy stacks. Advances in Mechanical Engineering and Transport, 1 (18), 110–123. https://doi.org/10.36910/automash.v1i18.767

- Xiong, Y., Liu, C., Wang, W., Jiang, R., Huang, B., Wang, D., Zhang, S. (2023). Assessment of machined surface for SiCf/SiC ceramic matrix composite during ultrasonic vibration-assisted milling-grinding. Ceramics International, 49 (3), 5345–5356. https://doi.org/10.1016/j.ceramint.2022.10.058

- Xiong, Y., Wang, W., Jiang, R., Huang, B., Liu, C. (2022). Feasibility and tool performance of ultrasonic vibration-assisted milling-grinding SiCf/SiC ceramic matrix composite. Journal of Materials Research and Technology, 19, 3018–3033. https://doi.org/10.1016/j.jmrt.2022.06.063

- Yakut, N. (2023). Cutting tool selection for machining metal matrix composites. Journal of Advances in Manufacturing Engineering. https://doi.org/10.14744/ytu.jame.2022.00008

- Liao, Z., Abdelhafeez, A., Li, H., Yang, Y., Diaz, O. G., Axinte, D. (2019). State-of-the-art of surface integrity in machining of metal matrix composites. International Journal of Machine Tools and Manufacture, 143, 63–91. https://doi.org/10.1016/j.ijmachtools.2019.05.006

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yrij Sychov, Oleksandr Bryniuk, Kyrylo Varodov, Yaroslav Grechaniuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.