Development of a grinder-miller with rolling working bodies for small farms

DOI:

https://doi.org/10.15587/1729-4061.2025.342305Keywords:

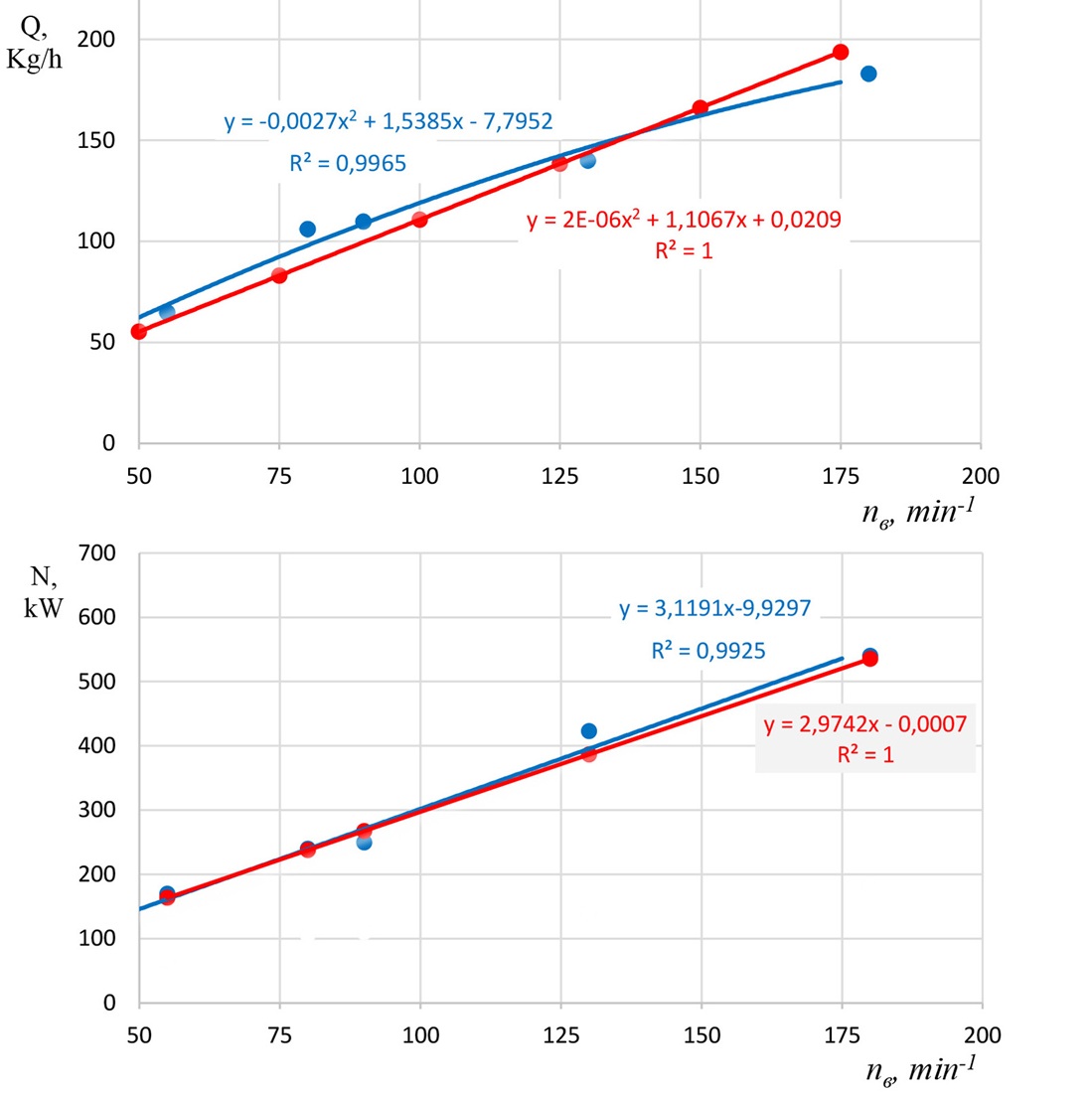

grinder-miller, interroller gap, productivity, required power, roll rotation frequencyAbstract

In sandy soils, skin resistance efficiency is critical, as it governs load capacity, settlement, and foundation cost. This study investigates pile foundations with directional surface asperities embedded in uniform sand to clarify the limited knowledge of how asperity orientation (cranial vs. caudal), geometric ratio (L / H), and pile diameter affect axial load transfer. Experimental tests were conducted on steel piles with diameters of 10, 12, and 15.85 mm under smooth, cranial, and caudal conditions with L / H ratios of 20, 26.67, and 33.33. Axial compression tests following ASTM D1143-20 in controlled dry sand provided ultimate load and shaft resistance data, validated by one-way ANOVA. The results show that cranial asperities consistently outperformed other surfaces, with the Cr L / H 20 configuration on the 15.85 mm pile reaching 0.368 kN, a 392.51% increase over smooth piles, while caudal asperities achieved only 134.30%. Cranial asperities also mobilized shaft resistance more uniformly along the pile, reducing end-bearing reliance. This performance is explained by stronger passive interaction at the pile-soil interface, which raises normal stress and friction mobilization. The distinctive feature of this research is the identification of the L / H ratio as a measurable design parameter, with L / H = 20 found to be optimal, in contrast to previous studies that described roughness only qualitatively. The findings demonstrate practical potential for applying cranial asperity designs in pile foundations for light- to medium-scale infrastructure on sandy soils, such as bridges, wharves, and transmission towers, enabling shorter or fewer piles without compromising safety while improving cost efficiency and geotechnical performance

References

- Morozov, N. (2023). Directions for the Development of Technical Progress in Animal Husbandry. XV International Scientific Conference “INTERAGROMASH 2022,” 414–424. https://doi.org/10.1007/978-3-031-21432-5_42

- Abilzhanuly, T., Iskakov, R., Abilzhanov, D., Darkhan, O. (2023). Determination of the average size of preliminary grinded wet feed particles in hammer grinders. Eastern-European Journal of Enterprise Technologies, 1 (1 (121)), 34–43. https://doi.org/10.15587/1729-4061.2023.268519

- Iskakov, R., Gulyarenko, A. (2025). Grinding and Mixing Uniformity in a Feed Preparation Device with Four-Sided Jagged Hammers and Impact-Mixing Mechanisms. AgriEngineering, 7 (6), 183. https://doi.org/10.3390/agriengineering7060183

- Iskakov, R., Sugirbay, A. (2023). Technologies for the Rational Use of Animal Waste: A Review. Sustainability, 15 (3), 2278. https://doi.org/10.3390/su15032278

- Roller grain crusher of the M series. Available at: https://kazagrotech.kz/katalog/selskohozyajstvennaya-tehnika/plyuschilki-i-drobilka/plyuschilki-valcovye-romill

- Li, Y.-W., Zhao, L.-L., Hu, E.-Y., Yang, K.-K., He, J.-F., Jiang, H.-S., Hou, Q.-F. (2019). Laboratory-scale validation of a DEM model of a toothed double-roll crusher and numerical studies. Powder Technology, 356, 60–72. https://doi.org/10.1016/j.powtec.2019.08.010

- Thivierge, A., Bouchard, J., Desbiens, A. (2021). Modelling the product mass flow rate of high-pressure grinding rolls. IFAC-PapersOnLine, 54 (11), 127–132. https://doi.org/10.1016/j.ifacol.2021.10.062

- Wu, S., Wang, S., Wang, G., Fan, L., Guo, J., Liu, Z. et al. (2024). Study on productivity of eccentric roll crusher based on theory and experiment. Minerals Engineering, 206, 108500. https://doi.org/10.1016/j.mineng.2023.108500

- Rodriguez, V. A., Campos, T. M., Barrios, G. K. P., Bueno, G., Tavares, L. M. (2023). A Hybrid PBM-DEM Model of High-Pressure Grinding Rolls Applied to Iron Ore Pellet Feed Pressing. KONA Powder and Particle Journal, 40, 262–276. https://doi.org/10.14356/kona.2023011

- Ciężkowski, P., Maciejewski, J., Bąk, S. (2017). Analysis of Energy Consumption of Crushing Processes – Comparison of One-Stage and Two-Stage Processes. Studia Geotechnica et Mechanica, 39 (2), 17–24. https://doi.org/10.1515/sgem-2017-0012

- El Ghobashy, H., Shaban, Y., Okasha, M., El-Reheem, S. A., Abdelgawad, M., Ibrahim, R. et al. (2023). Development and evaluation of a dual-purpose machine for chopping and crushing forage crops. Heliyon, 9 (4), e15460. https://doi.org/10.1016/j.heliyon.2023.e15460

- Savoie, P., Rotz, C. A., Bucholtz, H. F., Brook, R. C. (1982). Hay Harvesting System Losses and Drying Rates. Transactions of the ASAE, 25 (3), 0581–0585. https://doi.org/10.13031/2013.33576

- Tumuluru, J. S., Tabil, L. G., Song, Y., Iroba, K. L., Meda, V. (2014). Grinding energy and physical properties of chopped and hammer-milled barley, wheat, oat, and canola straws. Biomass and Bioenergy, 60, 58–67. https://doi.org/10.1016/j.biombioe.2013.10.011

- Rashidi, S., Rajamani, R. K., Fuerstenau, D. W. (2017). A Review of the Modeling of High Pressure Grinding Rolls. KONA Powder and Particle Journal, 34, 125–140. https://doi.org/10.14356/kona.2017017

- Moiceanu, G., Paraschiv, G., Voicu, G., Dinca, M., Negoita, O., Chitoiu, M., Tudor, P. (2019). Energy Consumption at Size Reduction of Lignocellulose Biomass for Bioenergy. Sustainability, 11 (9), 2477. https://doi.org/10.3390/su11092477

- Ebbing, M. A., Yacoubi, N., Naranjo, V., Sitzmann, W., Schedle, K., Gierus, M. (2022). Towards Large Particle Size in Compound Feed: Using Expander Conditioning Prior to Pelleting Improves Pellet Quality and Growth Performance of Broilers. Animals, 12 (19), 2707. https://doi.org/10.3390/ani12192707

- Cleary, P. W., Delaney, G. W., Sinnott, M. D., Cummins, S. J., Morrison, R. D. (2020). Advanced comminution modelling: Part 1 – Crushers. Applied Mathematical Modelling, 88, 238–265. https://doi.org/10.1016/j.apm.2020.06.049

- Savinykh, P., Aleshkin, A., Isupov, A., Kipriyanov, F., Skhlyaev, V. (2023). Modelling and calculation of stumulated oscillation for a crushing plant with vibration. E3S Web of Conferences, 383, 04071. https://doi.org/10.1051/e3sconf/202338304071

- M900 Crusher. Available at: https://dozaagro.com/oborudovanie/pluschenie/valtsovye/plyushchilka-m900/

- Al-Rabadi, G. (2013). Influence of hammer mill screen size on processing parameters and starch enrichment in milled sorghum. Cereal Research Communications, 41 (3), 493–499. https://doi.org/10.1556/crc.2013.0016

- Al-Eid, M., Qabatty, A., Kubaisi, R., Jaafar, A. A. K. (2025). Optimization of key operating parameters to enhance performance and energy efficiency of a hammer mill for corn grinding. Discover Applied Sciences, 7 (6). https://doi.org/10.1007/s42452-025-07263-z

- Abilzhanov, D. T. (2002). Development of a universal feed preparation unit for peasant and private subsidiary farms. Almaty, 30.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Tokhtar Abilzhanuly, Ruslan Iskakov, Daniyar Abilzhanov, Alexandr Gulyarenko, Olzhas Seipataliyev, Nurakhmet Khamitov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.