Identification of the mechanical performance of finger-jointed laminated merbau timber beams reinforced with carbon fiber reinforced polymer (CFRP)

DOI:

https://doi.org/10.15587/1729-4061.2025.342868Keywords:

merbau, glulam, beams, CFRP, reinforcement, bending, mechanical performance, MOE, MORAbstract

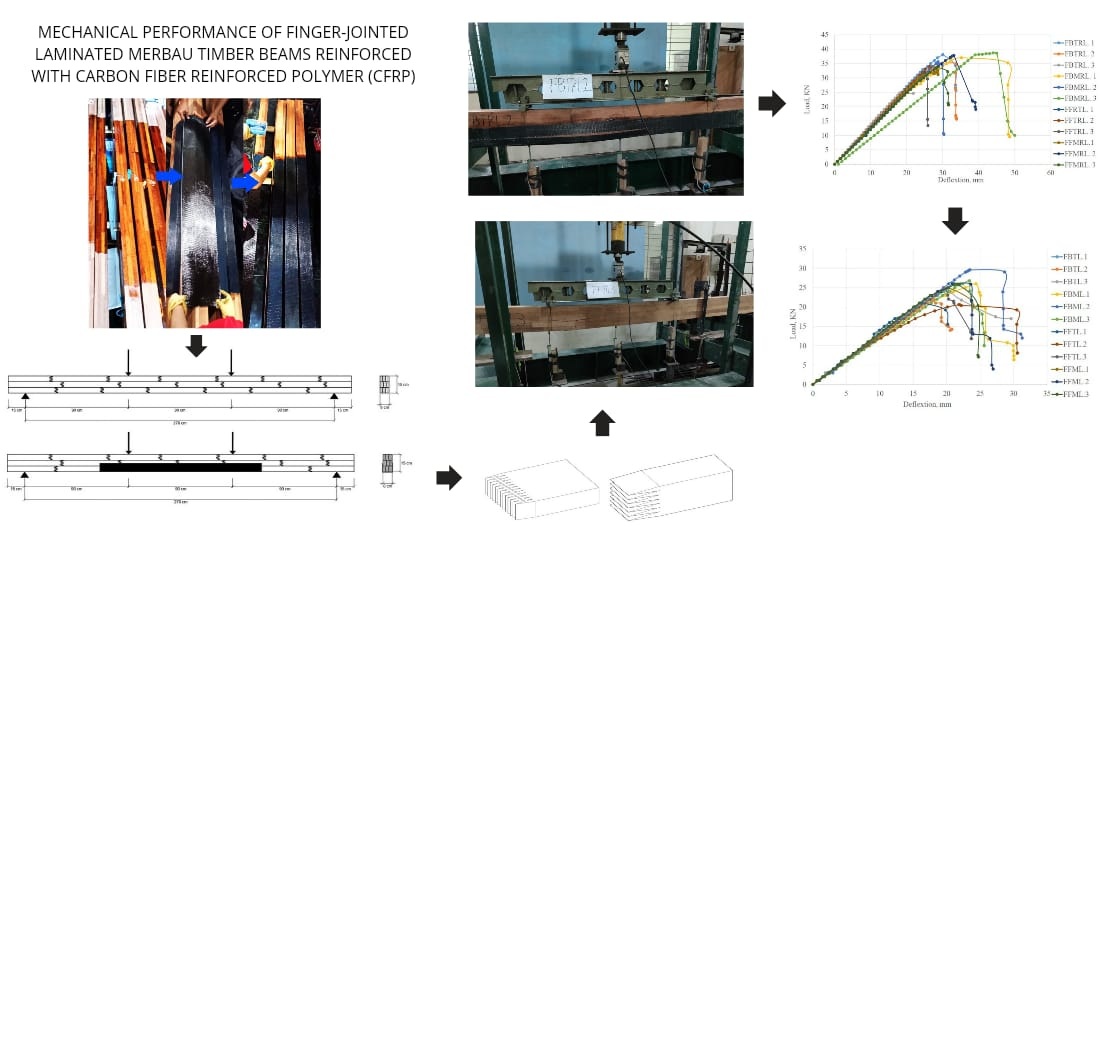

In this research, the mechanical properties and the reinforcement mechanism of finger-jointed laminated Merbau beams processed from wood-industry wastes are investigated and unreinforced specimens and externally U-shaped carbon fiber reinforced polymer (CFRP) strengthened beams are compared. The problem to be solved is the brittle failure and reduced flexural capacity of finger-jointed glulam; hence, it determines the combined impact of joint orientation (face-finger and face-butt), the number of lamination (three and five layers), and CFRP reinforcement on block-assembled beams with randomly distributed finger joints through four-point bending tests. The outcome of the study reveals that the use of CFRP has a huge impact on the flexural performance of the material, with the ultimate load being increased by 27.4–48.8% and the maximum bending moment being raised by 45.3% when compared to non-reinforced beams. The mid-point deflection at the maximum load has also increased by 6.5–51.4%, which shows a higher capacity for deformation and better ductility of the material.

The noted enhancements are credited to the successful shifting of the stress from the timber tension zone to the CFRP, lessening of stress concentration at the fingerjoint discontinuities, and the crack initiation and propagation taking longer time in random locations which together change the structural response from sudden brittle fracture to more stable damage progression leading up to failure. Among the tested configurations, face-butt beams have obtained the highest modulus of elasticity of 20.46 GPa (an 8.8% increase), while the five-lamina face-butt configuration strengthened by CFRP has reached the greatest modulus of rupture of 55.85 MPa (a 33.4% increase). The three-lamina face-finger beams showed the highest increase of MOR after reinforcement, being at 48.30 MPa (a 46.4% increase). Changing lamination from three to five layers raised flexural strength by 18.9%, suggesting a homogenization effect that improves stress distribution in laminated beams composed of blocks. All in all, the collaboration of finger-joint configuration, number of lamination, random block assembly, and CFRP strengthening has opened a door to convert Merbau wood waste into higher-performance engineered timber elements for low-carbon structural applications

References

- Kumar, V., Lo Ricco, M., Bergman, R. D., Nepal, P., Poudyal, N. C. (2024). Environmental impact assessment of mass timber, structural steel, and reinforced concrete buildings based on the 2021 international building code provisions. Building and Environment, 251, 111195. https://doi.org/10.1016/j.buildenv.2024.111195

- Dzhurko, D., Haacke, B., Haberbosch, A., Köhne, L., König, N., Lode, F. et al. (2024). Future buildings as carbon sinks: Comparative analysis of timber-based building typologies regarding their carbon emissions and storage. Frontiers in Built Environment, 10. https://doi.org/10.3389/fbuil.2024.1330105

- Sun, X., He, M., Li, Z. (2020). Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Construction and Building Materials, 249, 118751. https://doi.org/10.1016/j.conbuildmat.2020.118751

- Lara-Bocanegra, A. J., Majano-Majano, A., Crespo, J., Guaita, M. (2017). Finger-jointed Eucalyptus globulus with 1C-PUR adhesive for high performance engineered laminated products. Construction and Building Materials, 135, 529–537. https://doi.org/10.1016/j.conbuildmat.2017.01.004

- González-Prieto, O., Casas Mirás, J. M., Torres, L. O. (2021). Finger-jointing of green Eucalyptus globulus L. wood with one-component polyurethane adhesives. European Journal of Wood and Wood Products, 80 (2), 429–437. https://doi.org/10.1007/s00107-021-01770-7

- Hou, J., Taoum, A., Kotlarewski, N., Nolan, G. (2023). Study on the Effect of Finger-Joints on the Strengths of Laminations from Fiber-Managed Eucalyptus nitens. Forests, 14 (6), 1192. https://doi.org/10.3390/f14061192

- Le, S. T., Nguyen, T. N., Bui, D.-K., Ha, Q. P., Ngo, T. D. (2023). Modelling and Multi-Objective Optimisation of Finger Joints: Improving Flexural Performance and Minimising Wood Waste. Buildings, 13 (5), 1186. https://doi.org/10.3390/buildings13051186

- Karagöz İşleyen, Ü., Peker, İ. (2020). Effects of layer number and finger direction on bending behavior of glulam beams. BioResources, 15 (2), 4217–4233. https://doi.org/10.15376/biores.15.2.4217-4233

- Khelifa, M., Lahouar, M. A., Celzard, A. (2015). Flexural strengthening of finger-jointed Spruce timber beams with CFRP. Journal of Adhesion Science and Technology, 29 (19), 2104–2116. https://doi.org/10.1080/01694243.2015.1057395

- Rescalvo, F. J., Valverde-Palacios, I., Suarez, E., Gallego, A. (2018). Experimental and analytical analysis for bending load capacity of old timber beams with defects when reinforced with carbon fiber strips. Composite Structures, 186, 29–38. https://doi.org/10.1016/j.compstruct.2017.11.078

- Mercimek, Ö., Ghoroubi, R., Akkaya, S. T., Türer, A., Anıl, Ö., İşleyen, Ü. K. (2024). Flexural behavior of finger joint connected glulam wooden beams strengthened with CFRP strips. Structures, 66, 106853. https://doi.org/10.1016/j.istruc.2024.106853

- Park, H.-M., Gong, D.-M., Shin, M.-G., Byeon, H.-S. (2020). Bending Creep Properties of Cross-Laminated Wood Panels Made with Tropical Hardwood and Domestic Temperate Wood. Journal of the Korean Wood Science and Technology, 48 (5), 608–617. https://doi.org/10.5658/wood.2020.48.5.608

- Nadir, Y., Nagarajan, P., Ameen, M., Arif M, M. (2016). Flexural stiffness and strength enhancement of horizontally glued laminated wood beams with GFRP and CFRP composite sheets. Construction and Building Materials, 112, 547–555. https://doi.org/10.1016/j.conbuildmat.2016.02.133

- Ahmad, Z., Lum, W. C., Lee, S. H., Razlan, M. A., Wan Mohamad, W. H. (2017). Mechanical properties of finger jointed beams fabricated from eight Malaysian hardwood species. Construction and Building Materials, 145, 464–473. https://doi.org/10.1016/j.conbuildmat.2017.04.016

- Josué, D. F., Edgar, N. G., Joseph, N. A., Bosco, S. J., Bienvenu, K., Gael, A. T. U. (2022). Experimental Study of the Mechanical Behavior of Local Wood Terminalia Superba (Fraké) by Glued Wood Assembly According to the Beveled Configuration. Advances in Materials Science and Engineering, 2022, 1–12. https://doi.org/10.1155/2022/4059282

- Morin-Bernard, A., Blanchet, P., Dagenais, C., Achim, A. (2021). Glued-laminated timber from northern hardwoods: Effect of finger-joint profile on lamellae tensile strength. Construction and Building Materials, 271, 121591. https://doi.org/10.1016/j.conbuildmat.2020.121591

- Nurhayati, L., Dewi, S. M., Murti, W., Nuralinah, D. (2025). Identification of flexural performance of finger-jointed laminated timber beams reinforced with carbon fiber reinforced polymer. Eastern-European Journal of Enterprise Technologies, 5 (7 (137)), 17–27. https://doi.org/10.15587/1729-4061.2025.338430

- Galih, N. M., Yang, S. M., Yu, S. M., Kang, S. G. (2020). Study on the Mechanical Properties of Tropical Hybrid Cross Laminated Timber Using Bamboo Laminated Board as Core Layer. Journal of the Korean Wood Science and Technology, 48 (2), 245–252. https://doi.org/10.5658/wood.2020.48.2.245

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Lilis Nurhayati, Sri Murni Dewi, Wisnumurti Wisnumurti, Devi Nuralinah

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.