Improved vacuum evaporator for concentrating fruit and berry raw materials

DOI:

https://doi.org/10.15587/1729-4061.2025.343573Keywords:

vacuum evaporator, film electric heater, concentration, fruit and berry paste, mixer with heating bladesAbstract

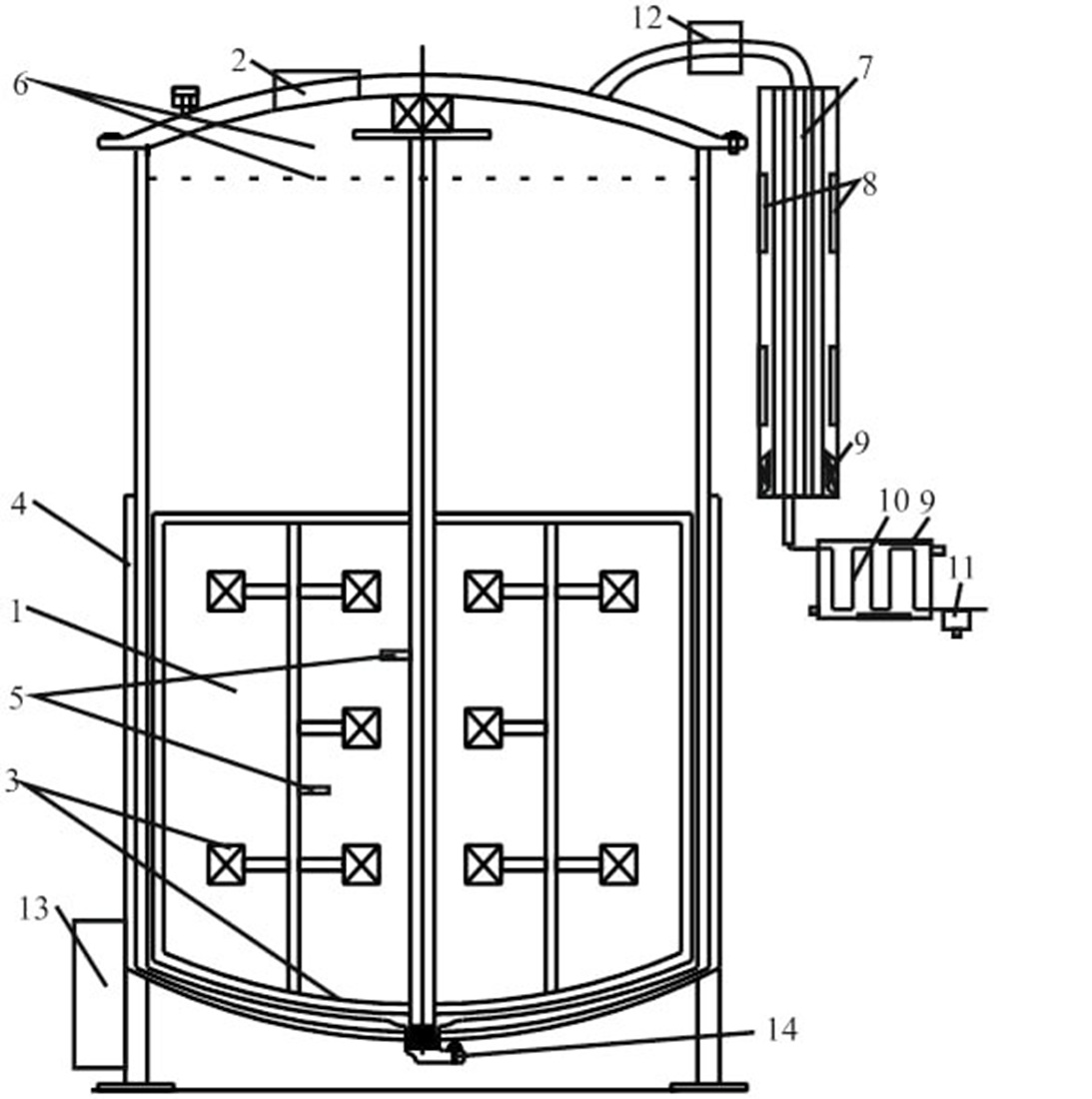

This study considers the process of heat and mass transfer during the boiling of fruit and berry pastes in a vacuum evaporator with a mixer that has heating blades. The vacuum evaporator has been improved by modernizing the heat supply system with a flexible film-like electric heater of the radiant type. The heating element is evenly placed on the outer surface of the working container; the unified mixer has its own heating surface with an area of 0.7 m2. This solution not only provides a stable thermal field throughout the volume of the apparatus but also reduces the time for the system to enter the operating mode. In addition, this solution makes it possible to reduce the inertia of the heating process, improve resource efficiency, and avoid local overheating of the product, which is especially important when boiling thermolabile fruit and berry masses.

The process of boiling a semi-finished product from apples, jujubes, and blueberries was tested. It was found that at a temperature of 25°C, a paste with a mass fraction of dry matter of 30% has a dynamic viscosity coefficient of 428 Pa∙s, which is 1.5 times higher than that of a puree with 15% dry matter (290 Pa∙s). It was determined that under boiling conditions at temperatures of 52…55°C and a residual pressure of 13…16 kPa, the effective viscosity of a product with a dry matter content of 15 to 30% is within 12…28 Pa∙s (shear rate of 1 s⁻1). The transient characteristic during heating in the improved apparatus is 30% less than that in the basic one. The metal consumption indicators of the improved structure are reduced by 45%, and the boiling time of fruit and berry puree (from 15% to 30% dry matter) is reduced by 16%, which is explained by the increase in the heating surface to a value of 4.4 m2. The specific heat consumption for heating the system decreased from 134.5 to 119 kJ/kg, which confirms the positive effect of the structural solution proposed in this work

References

- Chechitko, V., Antoniv, A., Adamchuk, L. (2024). Analytical review of the market of raw materials and innovative technologies of health-improving food products of plant origin. Animal Science and Food Technology, 15 (3), 115–133. https://doi.org/10.31548/animal.3.2024.115

- Vyrobnytstvo orhanichnoi silhospproduktsiyi ta syrovyny (2014). Ahrobiznes sohodni. Available at: https://agro-business.com.ua/agro/u-pravovomu-poli/item/1858-vyrobnytstvo-orhanichnoi-silhospproduktsii-ta-syrovyny.html

- Misra, N. N., Koubaa, M., Roohinejad, S., Juliano, P., Alpas, H., Inácio, R. S. et al. (2017). Landmarks in the historical development of twenty first century food processing technologies. Food Research International, 97, 318–339. https://doi.org/10.1016/j.foodres.2017.05.001

- Pylypenko, O. (2017). Development of Ukrainian Food Industry. Scientific Works of NUFT, 23 (3), 15–25. Available at: http://www.irbis-nbuv.gov.ua/cgi-bin/irbis_nbuv/cgiirbis_64.exe?I21DBN=LINK&P21DBN=UJRN&Z21ID=&S21REF=10&S21CNR=20&S21STN=1&S21FMT=ASP_meta&C21COM=S&2_S21P03=FILA=&2_S21STR=Npnukht_2017_23_3_4

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chervonyi, V., Omelchenko, O., Sabadash, S. et al. (2018). Universal multifunctional device for heat and mass exchange processes during organic raw material processing. Eastern-European Journal of Enterprise Technologies, 6 (1 (96)), 47–54. https://doi.org/10.15587/1729-4061.2018.148443

- Huang, L., Bai, L., Zhang, X., Gong, S. (2019). Re-understanding the antecedents of functional foods purchase: Mediating effect of purchase attitude and moderating effect of food neophobia. Food Quality and Preference, 73, 266–275. https://doi.org/10.1016/j.foodqual.2018.11.001

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

- O’Shea, N., Ktenioudaki, A., Smyth, T. P., McLoughlin, P., Doran, L., Auty, M. A. E. et al. (2015). Physicochemical assessment of two fruit by-products as functional ingredients: Apple and orange pomace. Journal of Food Engineering, 153, 89–95. https://doi.org/10.1016/j.jfoodeng.2014.12.014

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chuiko, L., Yakovets, L., Pugach, A. et al. (2022). Improving the production technology of functional paste-like fruit-and-berry semi-finished products. Eastern-European Journal of Enterprise Technologies, 4 (11 (118)), 43–52. https://doi.org/10.15587/1729-4061.2022.262924

- Marco, S.-C., Adrien, S., Isabelle, M., Manuel, V.-O., Dominique, P. (2019). Flash Vacuum-Expansion Process: Effect on the Sensory, Color and Texture Attributes of Avocado (Persea americana) Puree. Plant Foods for Human Nutrition, 74 (3), 370–375. https://doi.org/10.1007/s11130-019-00749-3

- Zahorulko, A., Zagorulko, A., Kasabova, K., Liashenko, B., Postadzhiev, A., Sashnova, M. (2022). Improving a tempering machine for confectionery masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (116)), 6–11. https://doi.org/10.15587/1729-4061.2022.254873

- Habanova, M., Saraiva, J. A., Holovicova, M., Moreira, S. A., Fidalgo, L. G., Haban, M. et al. (2019). Effect of berries/apple mixed juice consumption on the positive modulation of human lipid profile. Journal of Functional Foods, 60, 103417. https://doi.org/10.1016/j.jff.2019.103417

- Boesveldt, S., Bobowski, N., McCrickerd, K., Maître, I., Sulmont-Rossé, C., Forde, C. G. (2018). The changing role of the senses in food choice and food intake across the lifespan. Food Quality and Preference, 68, 80–89. https://doi.org/10.1016/j.foodqual.2018.02.004

- Burdo, O. G., Burdo, A. K., Sirotyuk, I., V., Pour, D. R. (2017). Technologies of Selective Energy Supply at Evaporation of Food Solutes. Problemele Energeticii Regionale, 1 (33), 100–109. Available at: https://journal.ie.asm.md/assets/files/12_01_33_2017.pdf

- Kasabova, K., Zagorulko, A., Zahorulko, A., Shmatchenko, N., Simakova, O., Goriainova, I. et al. (2021). Improving pastille manufacturing technology using the developed multicomponent fruit and berry paste. Eastern-European Journal of Enterprise Technologies, 3 (11 (111)), 49–56. https://doi.org/10.15587/1729-4061.2021.231730

- Borchani, M., Masmoudi, M., Ben Amira, A., Abbès, F., Yaich, H., Besbes, S. et al. (2019). Effect of enzymatic treatment and concentration method on chemical, rheological, microstructure and thermal properties of prickly pear syrup. LWT, 113, 108314. https://doi.org/10.1016/j.lwt.2019.108314

- Taskila, S., Ahokas, M., Järvinen, J., Toivanen, J., Tanskanen, J. P. (2017). Concentration and Separation of Active Proteins from Potato Industry Waste Based on Low-Temperature Evaporation and Ethanol Precipitation. Scientifica, 2017, 1–6. https://doi.org/10.1155/2017/5120947

- Dolores Alvarez, M., Canet, W. (2013). Time-independent and time-dependent rheological characterization of vegetable-based infant purees. Journal of Food Engineering, 114 (4), 449–464. https://doi.org/10.1016/j.jfoodeng.2012.08.034

- Ahrens, M. U., Selvnes, H., Henke, L., Bantle, M., Hafner, A. (2024). Investigation on heat recovery strategies from low temperature food processing plants: Energy analysis and system comparison. Refrigeration Technology, 113 (1), 41–53. https://doi.org/10.17816/rf636197

- Ding, Z., Qin, F. G. F., Yuan, J., Huang, S., Jiang, R., Shao, Y. (2019). Concentration of apple juice with an intelligent freeze concentrator. Journal of Food Engineering, 256, 61–72. https://doi.org/10.1016/j.jfoodeng.2019.03.018

- Hobold, G. M., da Silva, A. K. (2019). Visualization-based nucleate boiling heat flux quantification using machine learning. International Journal of Heat and Mass Transfer, 134, 511–520. https://doi.org/10.1016/j.ijheatmasstransfer.2018.12.170

- Zahorulko, A., Zagorulko, A., Yancheva, M., Ponomarenko, N., Tesliuk, H., Silchenko, E. et al. (2020). Increasing the efficiency of heat and mass exchange in an improved rotary film evaporator for concentration of fruit-and-berry puree. Eastern-European Journal of Enterprise Technologies, 6 (8 (108)), 32–38. https://doi.org/10.15587/1729-4061.2020.218695

- Chen, X., Gao, Z., McFadden, B. R. (2020). Reveal Preference Reversal in Consumer Preference for Sustainable Food Products. Food Quality and Preference, 79, 103754. https://doi.org/10.1016/j.foodqual.2019.103754

- Zahorulko, A., Zagorulko, A., Kasabova, K., Shmatchenko, N. (2020). Improvement of zefir production by addition of the developed blended fruit and vegetable pasteinto its recipe. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 39–45. https://doi.org/10.15587/1729-4061.2020.185684

- Samokhvalova, O., Kasabova, K., Oliinyk, S. (2014). The influence of the enriching additives on the dough structure formation and baked muffins. Eastern-European Journal of Enterprise Technologies, 1 (10 (67)), 32–36. https://doi.org/10.15587/1729-4061.2014.20024

- Monastyryshchenskyi zavod kotelnoho obladnannia. Available at: https://tekom-zavod.com.ua/ua/about_us

- Cherevko, A., Mayak, O., Kostenko, S., Sardarov, A. (2019). Experimental and simulation modeling of the heat exchanche process while boiling vegetable juice. Progressive technique and technologies of food production enterprises, catering business and trade, 1 (29), 75–85. https://doi.org/10.5281/zenodo.3263532

- Samokhvalova, O., Kasabova, K., Shmatchenko, N., Zagorulko, A., Zahorulko, A. (2021). Improving the marmalade technology by adding a multicomponent fruit-and-berry paste. Eastern-European Journal of Enterprise Technologies, 6 (11 (114)), 6–14. https://doi.org/10.15587/1729-4061.2021.245986

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Aleksey Zagorulko, Valeriy Mikhaylov, Andrey Pak, Aleksey Gromov, Natalia Fedak, Andrii Puhach, Miushfik Bakirov, Kirilo Pavliuchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.