Establishing the influence of sunflower oil quality indicators on the efficiency of the transesterification catalyst

DOI:

https://doi.org/10.15587/1729-4061.2025.344900Keywords:

transesterification catalyst, potassium glyceroxide, chemical transesterification, sunflower oil, crystallization temperatureAbstract

The object of the study is the process of chemical transesterification of sunflower oil with increased mass fraction of moisture and acid value.

Transesterification technology allows obtaining fats with the necessary physico-chemical properties without changing the fatty acid composition. The problem of using alkaline catalysts is rapid deactivation under the influence of impurities present in the fatty raw material. The greatest influence is exerted by moisture and fatty acids.

Transesterification of sunflower oil with increased mass fraction of moisture and acid value in the presence of potassium glyceroxide, which is more resistant to deactivating impurities, was studied. Oil parameters: peroxide value 0.18 ½ O mmol/kg, acid value 0.08 mg KOH/g, mass fraction of moisture 0.05%, crystallization temperature –18.38°C.

Oil samples with mass fractions of moisture from 0.1 to 0.75% (obtained by adding water) were stored for two months under the following conditions: temperature (20±2) °C, air humidity not more than 70%. After storage, the acid value was measured in each sample and transesterification was performed. The efficiency of the process was assessed by the oil crystallization temperature.

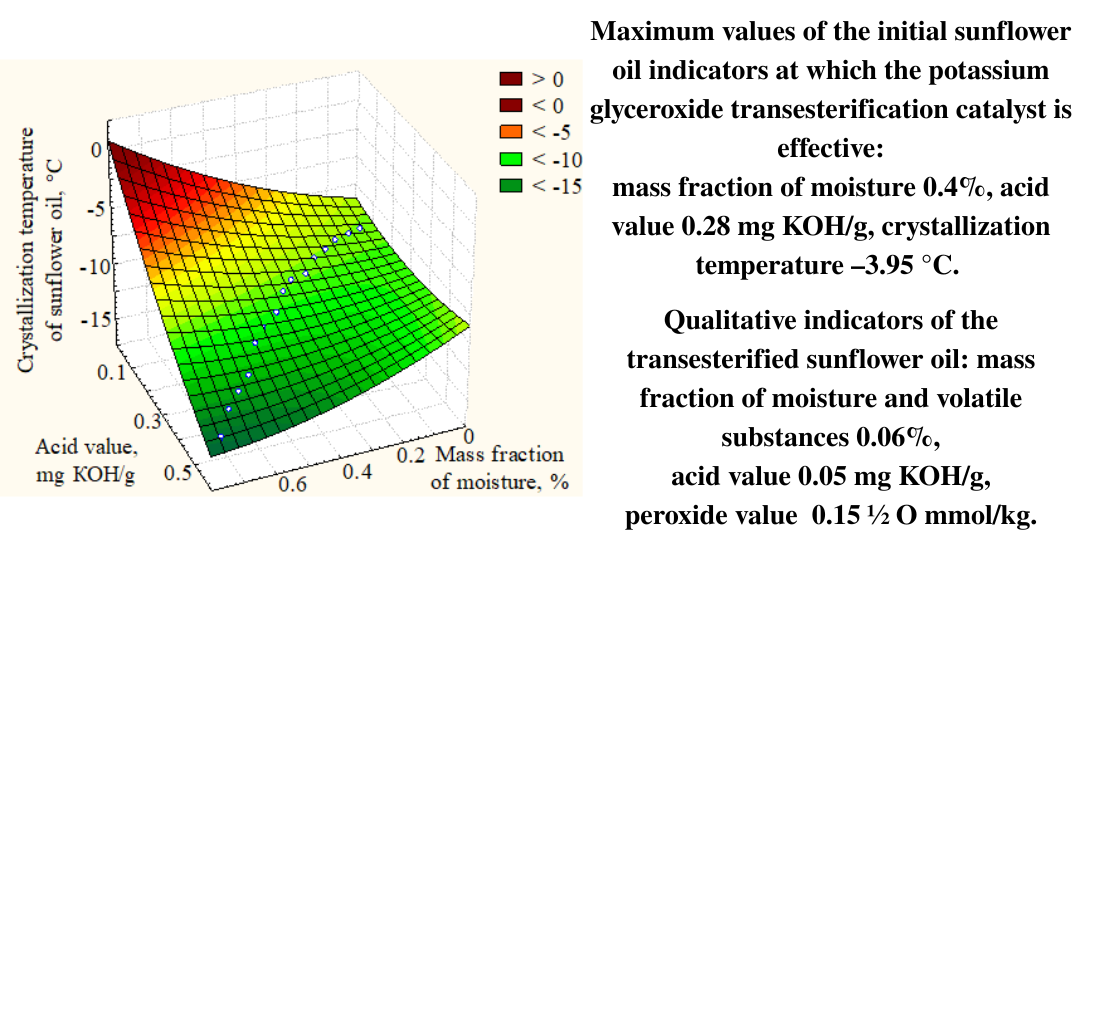

The maximum values of oil indicators at which the potassium glyceroxide catalyst is effective were established: mass fraction of moisture 0.4%, acid value 0.28 mg KOH/g. At the same time, the crystallization temperature of sunflower oil is –3.95°C, which corresponds to the maximum increase in the crystallization temperature of oil as a result of transesterification.

The results obtained make it possible to effectively transesterify sunflower and other types of non-standard quality oils without preliminary treatment. This will reduce the cost of production and increase the profitability of enterprises (depending on the indicators of non-standard raw materials).

References

- Sulaiman, N. F., Gunasekaran, S. S., Mohd Nashruddin, S. N. A., Mohd Nashruddin, S. N. A., Sofiah, A. G. N., Abd Mubin, M. H., Lee, S. L. (2025). Advancements in transesterification of waste cooking oil to biodiesel using rare earth metal oxide catalysts: A bibliometric analysis and future prospects. Fuel, 394, 135158. https://doi.org/10.1016/j.fuel.2025.135158

- Almazrouei, M., Elagroudy, S., Janajreh, I. (2019). Transesterification of waste cooking oil: Quality assessment via thermogravimetric analysis. Energy Procedia, 158, 2070–2076. https://doi.org/10.1016/j.egypro.2019.01.478

- Razzak, S. A., Zakir Hossain, S. M., Ahmed, U., Hossain, M. M. (2025). Cleaner biodiesel production from waste oils (cooking/vegetable/frying): Advances in catalytic strategies. Fuel, 393, 134901. https://doi.org/10.1016/j.fuel.2025.134901

- Al-Sakkari, E. G., Abdeldayem, O. M., El-Sheltawy, S. T., Abadir, M. F., Soliman, A., Rene, E. R., Ismail, I. (2020). Esterification of high FFA content waste cooking oil through different techniques including the utilization of cement kiln dust as a heterogeneous catalyst: A comparative study. Fuel, 279, 118519. https://doi.org/10.1016/j.fuel.2020.118519

- Korchak, M., Bliznjuk, O., Nekrasov, S., Gavrish, T., Petrova, O., Shevchuk, N., Strikha, L. et al. (2022). Development of rational technology for sodium glyceroxide obtaining. Eastern-European Journal of Enterprise Technologies, 5 (6 (119)), 15–21. https://doi.org/10.15587/1729-4061.2022.265087

- Korchak, M., Bragin, O., Petrova, O., Shevchuk, N., Strikha, L., Stankevych, S. et al. (2022). Development of transesterification model for safe technology of chemical modification of oxidized fats. Eastern-European Journal of Enterprise Technologies, 6 (6 (120)), 14–19. https://doi.org/10.15587/1729-4061.2022.266931

- Asfaw, B. T., Gari, M. T., Jayakumar, M. (2025). Transesterification of biodiesel from non-edible oils using heterogeneous base catalysts: A comprehensive review of potential renewable biomass feedstocks. Chemical Engineering Journal, 511, 162028. https://doi.org/10.1016/j.cej.2025.162028

- Abu-Ghazala, A. H., Abdelhady, H. H., Mazhar, A. A., El-Deab, M. S. (2023). Exceptional room temperature catalytic transesterification of waste cooking oil to biodiesel using environmentally-benign K2CO3/γ-Al2O3 nano-catalyst. Chemical Engineering Journal, 474, 145784. https://doi.org/10.1016/j.cej.2023.145784

- Prajapati, N., Singh Kachhwaha, S., Kodgire, P., Kumar Vij, R. (2025). A novel high-speed homogenizer assisted process intensification technique for biodiesel production using soya acid oil: Process optimization, kinetic and thermodynamic modelling. Energy Conversion and Management, 324, 119302. https://doi.org/10.1016/j.enconman.2024.119302

- Miladinović, M. R., Krstić, J. B., Zdujić, M. V., Veselinović, L. M., Veljović, D. N., Banković-Ilić, I. B. et al. (2022). Transesterification of used cooking sunflower oil catalyzed by hazelnut shell ash. Renewable Energy, 183, 103–113. https://doi.org/10.1016/j.renene.2021.10.071

- Liu, J., Lin, T., Niu, S., Zhu, J., Yang, Z., Geng, J. et al. (2024). Transesterification of acidic palm oil using solid waste/CaO as a bifunctional catalyst. Fuel, 362, 130913. https://doi.org/10.1016/j.fuel.2024.130913

- Chaveanghong, S., Smith, S. M., Smith, C. B., Luengnaruemitchai, A., Boonyuen, S. (2018). Simultaneous transesterification and esterification of acidic oil feedstocks catalyzed by heterogeneous tungsten loaded bovine bone under mild conditions. Renewable Energy, 126, 156–162. https://doi.org/10.1016/j.renene.2018.03.036

- Chen, Y.-C., Lin, D.-Y., Chen, B.-H. (2017). Transesterification of acid soybean oil for biodiesel production using lithium metasilicate catalyst prepared from diatomite. Journal of the Taiwan Institute of Chemical Engineers, 79, 31–36. https://doi.org/10.1016/j.jtice.2017.05.001

- Al-Saadi, A., Mathan, B., He, Y. (2020). Biodiesel production via simultaneous transesterification and esterification reactions over SrO–ZnO/Al2O3 as a bifunctional catalyst using high acidic waste cooking oil. Chemical Engineering Research and Design, 162, 238–248. https://doi.org/10.1016/j.cherd.2020.08.018

- Yasvanthrajan, N., Sivakumar, P., Muthukumar, K., Thanabalan, M., Arunagiri, A. (2025). Ultrasound assisted lipase catalysed transesterification using waste cottonseed oil. Journal of the Taiwan Institute of Chemical Engineers, 177, 106076. https://doi.org/10.1016/j.jtice.2025.106076

- Li, L., Li, L., Ma, J., Xie, F. (2024). Biodiesel production from the transesterification of waste cooking oil via CaO/HAP/MnFe@K magnetic nanocatalyst derived from eggshells and chicken bones: Diesel engine and kinetic studies. Renewable Energy, 237, 121563. https://doi.org/10.1016/j.renene.2024.121563

- Shah, M., Poudel, J., Kwak, H., Oh, S. C. (2015). Kinetic analysis of transesterification of waste pig fat in supercritical alcohols. Process Safety and Environmental Protection, 98, 239–244. https://doi.org/10.1016/j.psep.2015.08.002

- Maddikeri, G. L., Pandit, A. B., Gogate, P. R. (2013). Ultrasound assisted interesterification of waste cooking oil and methyl acetate for biodiesel and triacetin production. Fuel Processing Technology, 116, 241–249. https://doi.org/10.1016/j.fuproc.2013.07.004

- Korchak, M., Shostia, A., Usenko, S., Floka, L., Hnitii, N., Morozova, L. et al. (2024). Determination of rational parameters of chemical transesterification technology of sunflower oil. Eastern-European Journal of Enterprise Technologies, 5 (6 (131)), 26–33. https://doi.org/10.15587/1729-4061.2024.313095

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Mykola Korchak, Vladyslav Knysh, Anatolii Shostia, Svitlana Usenko, Yevgenia Hmelnitska, Zoja Rachynska, Volodymyr Viaskov, Ivan Kostenko, Vita Glavatchuk, Sergii Zygin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.