Improved thermoradiative belt dryer with air recuperation and autonomous ventilation

DOI:

https://doi.org/10.15587/1729-4061.2025.345352Keywords:

low-temperature drying, mobile IR dryer, unified conveyor belt, autonomous ventilation, secondary air recoveryAbstract

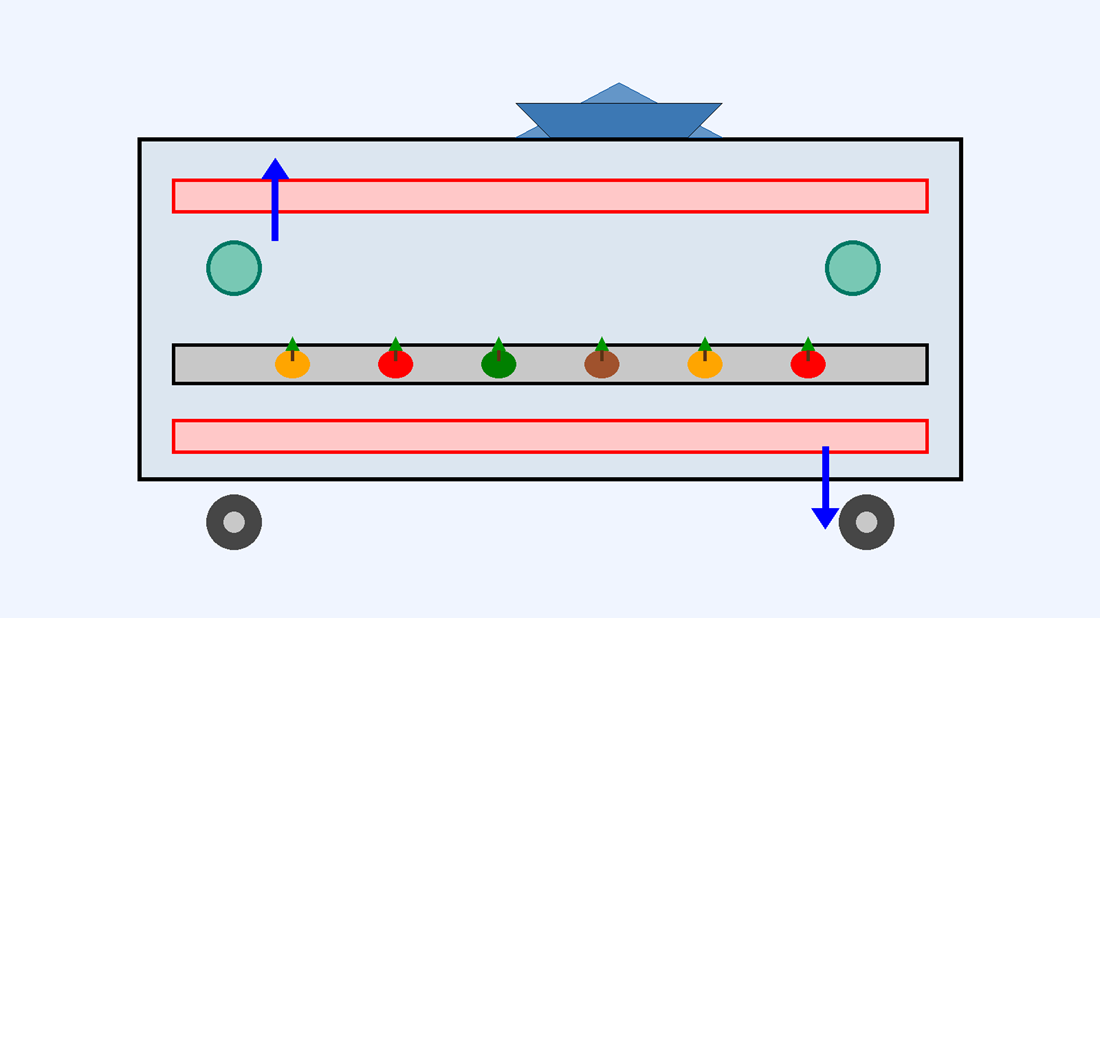

This study considers the process of IR drying of organic raw materials and semi-finished products of mixed composition. A limitation of this process is the insufficient uniformity of drying and preservation of biologically active substances. To address this challenge, the structure of a film-like electric heater of radiating type has been improved by combined heat supply and conductive drying under autonomous ventilation conditions (15…30 W). A universal conveyor belt with replaceable modules expands the range of organic agricultural raw materials and semi-finished products of mixed composition during low-temperature drying (45…65°C).

The drying duration is reduced by 30…35% with an increase in the residual content of biologically active substances by 15…20% compared to the base device. For apples of the Gala variety, the residual content of vitamin C after IR drying was 82.0 ± 3.1 mg/100 g, which is 20% more than in the prototype (68.0 ± 2.5 mg/100 g). In carrots of the Shantane variety, the residual content of β-carotene after IR drying was 87 ± 2.5%, which is 17% higher than in the prototype (70 ± 3%). In chokeberry, the preservation of anthocyanins is 92 ± 3%, in contrast to the prototype (76 ± 4%), in parsley, the preservation of chlorophylls is 82 ± 4% (the prototype is 65 ± 5%). In meat and vegetable semi-finished products, the preservation of antioxidant activity is 84 ± 2% (versus 72 ± 3%).

The combination of film-like heating, recovery of secondary warm air, autonomous ventilation by Peltier elements, solar collector, and photovoltaic panel with battery contributes to resource saving (20…30%) and stabilization of the temperature field (ΔT = 12…18°C). The results confirm the functional and modular properties of the improved device for the “from farm to fork” system for the production of functional semi-finished products with a high degree of readiness.

References

- Augustin, M. A., Riley, M., Stockmann, R., Bennett, L., Kahl, A., Lockett, T. et al. (2016). Role of food processing in food and nutrition security. Trends in Food Science & Technology, 56, 115–125. https://doi.org/10.1016/j.tifs.2016.08.005

- Nowacka, M., Matys, A., Witrowa-Rajchert, D. (2024). Innovative Technologies for Improving the Sustainability of the Food Drying Industry. Current Food Science and Technology Reports, 2 (2), 231–239. https://doi.org/10.1007/s43555-024-00026-8

- Venkateswarlu, K., Reddy, S. V. K. (2024). Recent trends on energy-efficient solar dryers for food and agricultural products drying: a review. Waste Disposal & Sustainable Energy, 6 (3), 335–353. https://doi.org/10.1007/s42768-024-00193-3

- Chojnacka, K., Mikula, K., Izydorczyk, G., Skrzypczak, D., Witek-Krowiak, A., Moustakas, K. et al. (2021). Improvements in drying technologies - Efficient solutions for cleaner production with higher energy efficiency and reduced emission. Journal of Cleaner Production, 320, 128706. https://doi.org/10.1016/j.jclepro.2021.128706

- Das, B., Singh, P., Kalita, P. (2025). Performance Evaluation of a Mixed-Mode solar dryer with PCM-based energy storage for efficient drying of Baccaurea ramiflora. Solar Energy, 288, 113279. https://doi.org/10.1016/j.solener.2025.113279

- Huang, L., Bai, L., Zhang, X., Gong, S. (2019). Re-understanding the antecedents of functional foods purchase: Mediating effect of purchase attitude and moderating effect of food neophobia. Food Quality and Preference, 73, 266–275. https://doi.org/10.1016/j.foodqual.2018.11.001

- Kiptelaya, L., Zagorulko, A., Zagorulko, A. (2015). Improvement of equipment for manufacture of vegetable convenience foods. Eastern-European Journal of Enterprise Technologies, 2 (10 (74)), 4–8. https://doi.org/10.15587/1729-4061.2015.39455

- An, J., Xie, H., Yan, J., Wei, H., Wu, Y., Liao, X. (2024). A review of applications of energy analysis: Grain, fruit and vegetable drying technology. Energy Reports, 12, 5482–5506. https://doi.org/10.1016/j.egyr.2024.11.037

- Majumder, P., Deb, B., Gupta, R., Sablani, S. S. (2022). A comprehensive review of fluidized bed drying: Sustainable design approaches, hydrodynamic and thermodynamic performance characteristics, and product quality. Sustainable Energy Technologies and Assessments, 53, 102643. https://doi.org/10.1016/j.seta.2022.102643

- Haron, N. S., Zakaria, J. H., Mohideen Batcha, M. F. (2017). Recent advances in fluidized bed drying. IOP Conference Series: Materials Science and Engineering, 243, 012038. https://doi.org/10.1088/1757-899x/243/1/012038

- Cherevko, O., Mikhaylov, V., Zahorulko, A., Zagorulko, A., Gordienko, I. (2021). Development of a thermal-radiation single-drum roll dryer for concentrated food stuff. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 25–32. https://doi.org/10.15587/1729-4061.2021.224990

- Zahorulko, A., Cherevko, O., Zagorulko, A., Yancheva, M., Budnyk, N., Nakonechna, Y. et al. (2021). Design of an apparatus for low-temperature processing of meat delicacies. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 6–12. https://doi.org/10.15587/1729-4061.2021.240675

- Zahorulko, A., Zagorulko, A., Kasabova, K., Shmatchenko, N. (2020). Improvement of zefir production by addition of the developed blended fruit and vegetable pasteinto its recipe. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 39–45. https://doi.org/10.15587/1729-4061.2020.185684

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chuiko, L., Yakovets, L., Pugach, A. et al. (2022). Improving the production technology of functional paste-like fruit-and-berry semi-finished products. Eastern-European Journal of Enterprise Technologies, 4 (11 (118)), 43–52. https://doi.org/10.15587/1729-4061.2022.262924

- Mishra, L., Hauchhum, L., Gupta, R. (2022). Development and performance investigation of a novel solar-biomass hybrid dryer. Applied Thermal Engineering, 211, 118492. https://doi.org/10.1016/j.applthermaleng.2022.118492

- Park, Y., Chang, Y.-S., Park, J.-H., Yang, S.-Y., Chung, H., Jang, S.-K. et al. (2016). Energy Efficiency of Fluidized Bed Drying for Wood Particles. Journal of the Korean Wood Science and Technology, 44 (6), 821–827. https://doi.org/10.5658/wood.2016.44.6.821

- Waskale, H., Bhong, M. (2019). Forced Convective Drying Of Potato Chips with Air Recirculation. Available at: https://www.researchgate.net/publication/333338784_Forced_Convective_Drying_Of_Potato_Chips_with_Air_Recirculation

- Rakshamuthu, S., Jegan, S., Joel Benyameen, J., Selvakumar, V., Anandeeswaran, K., Iyahraja, S. (2021). Experimental analysis of small size solar dryer with phase change materials for food preservation. Journal of Energy Storage, 33, 102095. https://doi.org/10.1016/j.est.2020.102095

- Lee, D.-J., Jangam, S., Mujumdar, A. S. (2013). Some Recent Advances in Drying Technologies to Produce Particulate Solids. KONA Powder and Particle Journal, 30, 69–83. https://doi.org/10.14356/kona.2013010

- Faure, E., Shcherba, A., Stupka, B., Voronenko, I., Baikenov, A. (2023). A Method for Reliable Permutation Transmission in Short-Packet Communication Systems. Information Technology for Education, Science, and Technics, 177–195. https://doi.org/10.1007/978-3-031-35467-0_12

- Nejadi, J., Nikbakht, A. M. (2016). Numerical Simulation of Corn Drying in a Hybrid Fluidized Bed‐Infrared Dryer. Journal of Food Process Engineering, 40 (2). https://doi.org/10.1111/jfpe.12373

- Aviara, N. A., Onuoha, L. N., Falola, O. E., Igbeka, J. C. (2014). Energy and exergy analyses of native cassava starch drying in a tray dryer. Energy, 73, 809–817. https://doi.org/10.1016/j.energy.2014.06.087

- Borel, L. D. M. S., Marques, L. G., Prado, M. M. (2020). Performance evaluation of an infrared heating-assisted fluidized bed dryer for processing bee-pollen grains. Chemical Engineering and Processing - Process Intensification, 155, 108044. https://doi.org/10.1016/j.cep.2020.108044

- Lv, W., Li, D., Lv, H., Jin, X., Han, Q., Su, D., Wang, Y. (2019). Recent development of microwave fluidization technology for drying of fresh fruits and vegetables. Trends in Food Science & Technology, 86, 59–67. https://doi.org/10.1016/j.tifs.2019.02.047

- Golmohammadi, M., Assar, M., Rajabi-Hamaneh, M., Hashemi, S. J. (2015). Energy efficiency investigation of intermittent paddy rice dryer: Modeling and experimental study. Food and Bioproducts Processing, 94, 275–283. https://doi.org/10.1016/j.fbp.2014.03.004

- Aktaş, M., Khanlari, A., Amini, A., Şevik, S. (2017). Performance analysis of heat pump and infrared–heat pump drying of grated carrot using energy-exergy methodology. Energy Conversion and Management, 132, 327–338. https://doi.org/10.1016/j.enconman.2016.11.027

- Ichise, T., Tatemoto, Y. (2022). Numerical analysis of drying characteristics of frozen material immersed in fluidized bed at low temperature under reduced pressure. Advanced Powder Technology, 33 (8), 103661. https://doi.org/10.1016/j.apt.2022.103661

- Granaturov, V., Kaptur, V., Politova, I. (2016). Determination of tariffs on telecommunication services based on modeling the cost of their providing: methodological and practical aspects of application. Economic Annals-ХХI, 156 (1-2), 83–87. https://doi.org/10.21003/ea.v156-0019

- Potapskyi, O. V., Fesiun, S. V., Pylypenko, O. Yu., Babych, I. M. (2020). Pat. No. 147229 UA. Bahatozonalna termoelektrychna susharka. No. u202007428; declareted: 23.11.2020; published: 22.04.2021. Available at: https://sis.nipo.gov.ua/uk/search/detail/1589442/

- Usama, M., Ali, Z., Ndukwu, M. C., Sathyamurthy, R. (2023). The energy, emissions, and drying kinetics of three-stage solar, microwave and desiccant absorption drying of potato slices. Renewable Energy, 219, 119509. https://doi.org/10.1016/j.renene.2023.119509

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Andrii Zahorulko, Iryna Voronenko, Larysa Bal-Prylypko, Maksym Riabovol, Mykhailo Marchenko, Tetiana Zhelievа, Serhii Babaiev, Eldar Ibaiev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.