Identifying the effect of the temperature regime of a heat generating unit on the efficiency of the electrohydroimpulse degreasing of organic materials

DOI:

https://doi.org/10.15587/1729-4061.2025.347018Keywords:

organic materials, electrohydroimpulse method, cavitation, inertial hydrodynamic installation, valuable componentsAbstract

The object of the study is to processing of organic waste using less energy-consuming technologies. This article discusses the issues of improving energy conversion methods aimed at efficient processing of organic waste using less energy-consuming technologies.

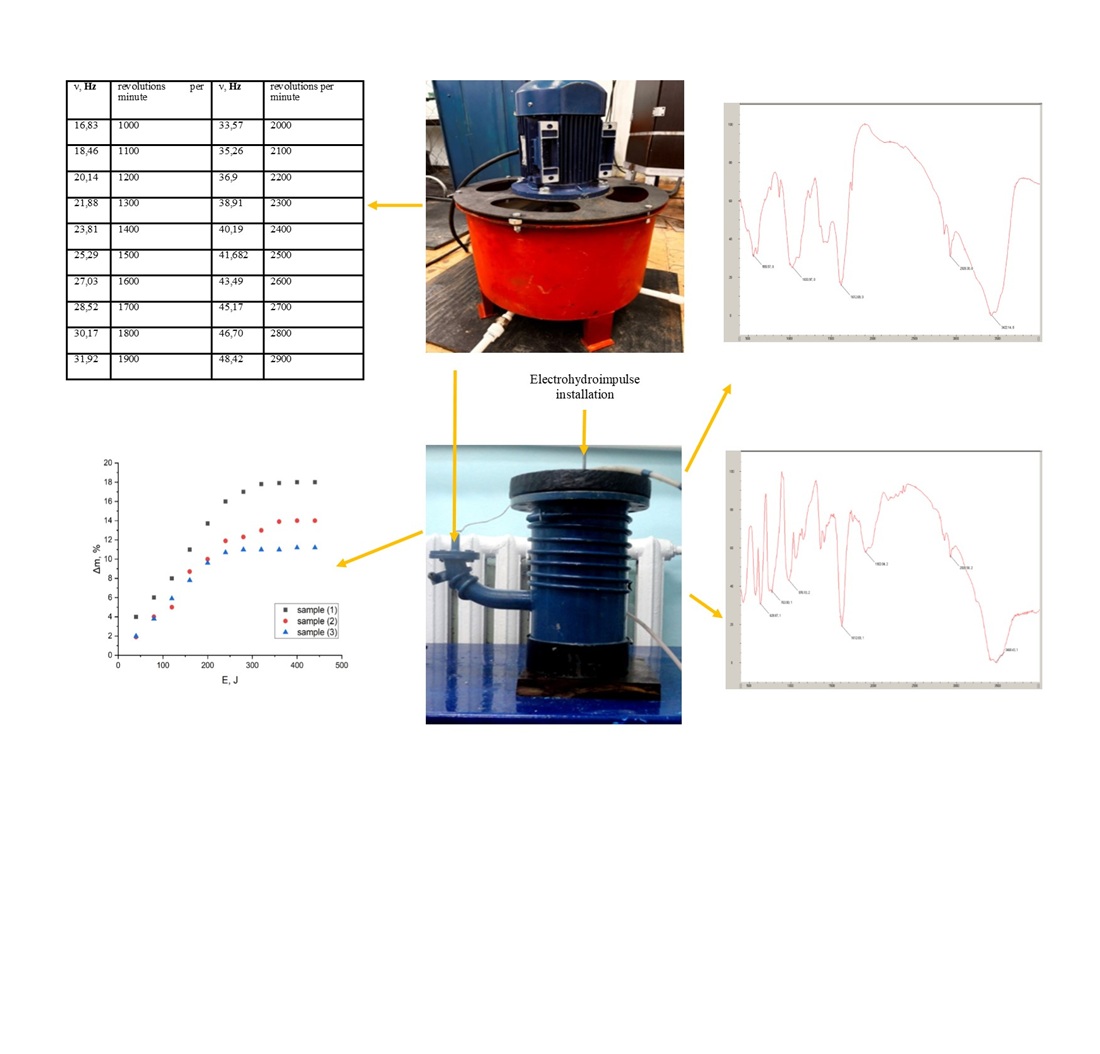

Shock waves and local micro sources of high temperatures and pressures destroy cellular and intercellular structures of organic material. In the course of experimental work, it was found that the effective isolation of valuable components from waste organic material depends on the discharge voltage and the capacity of the storage capacitor. During operation, the optimal temperature of the working medium was set in the range of 36−50°C and the maximum product yield was observed at an energy in the range of 120−240 J on the switching device. The maintenance of this temperature range is provided by a hydrodynamic installation, which creates a constant and uniform heating of the working cell of the electrohydroimpulse installation. Due to intensive hydrodynamic processes such as turbulence, cavitation, and local pressure drops, heat is distributed evenly, which ensures efficient processing of organic materials and process stability. The triglyceride fraction is an indispensable source of raw materials not only in the food industry, but also for medicine, construction, and industry (for lubricating machine parts and measuring instruments)

References

- Guo, G., Lu, K., Xu, S., Yuan, J., Bai, T., Yang, K., He, Z. (2023). Effects of in-nozzle liquid fuel vortex cavitation on characteristics of flow and spray: Numerical research. International Communications in Heat and Mass Transfer, 148, 107040. https://doi.org/10.1016/j.icheatmasstransfer.2023.107040

- Regulation (EC) No 1774/2002 of the European Parliament and of the Council of 3 October 2002 laying down health rules concerning animal by-products not intended for human consumption. Available at: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32002R1774

- Jankowski, K. J., Nogalska, A. (2022). Meat and Bone Meal and the Energy Balance of Winter Oilseed Rape – A Case Study in North-Eastern Poland. Energies, 15 (11), 3853. https://doi.org/10.3390/en15113853

- Möller, K., Oberson, A., Bünemann, E. K., Cooper, J., Friedel, J. K., Glæsner, N. et al. (2018). Improved Phosphorus Recycling in Organic Farming: Navigating Between Constraints. Advances in Agronomy, 159–237. https://doi.org/10.1016/bs.agron.2017.10.004

- Polášek, T., Hružík, L., Bureček, A., Ledvoň, M. (2022). Experimental Analysis of Flow Through Throttle Valve During Gaseous Cavitation. MATEC Web of Conferences, 369, 02008. https://doi.org/10.1051/matecconf/202236902008

- Shumilov, I. (2016). Fluid Temperature of Aero Hydraulic Systems. Machines and Plants: Design and Exploiting, 16 (02). https://doi.org/10.7463/aplts.0216.0837432

- Sydykov, Sh. K., Umbetkulov, E. K., Alibek, N. B. (2016). Pat. No. 1585 RK. Heat pump system of autonomous heat supply. publ. 2016, Bul. No. 8.

- Luneva, S. K., Lepesh, A. G. (2015). Research of efficiency of functioning of the heat pump. Technical and technological problems of the service, 4 (34), 30–35.

- Kowalski, Z., Banach, M., Makara, A. (2020). Optimisation of the co-combustion of meat–bone meal and sewage sludge in terms of the quality produced ashes used as substitute of phosphorites. Environmental Science and Pollution Research, 28 (7), 8205–8214. https://doi.org/10.1007/s11356-020-11022-5

- Załuszniewska, A., Nogalska, A. (2020). The Effect of Meat and Bone Meal (MBM) on the Seed Yield and Quality of Winter Oilseed Rape. Agronomy, 10 (12), 1952. https://doi.org/10.3390/agronomy10121952

- Vasina, M., Hruzik, L., Burecek, A. (2018). Energy and Dynamic Properties of Hydraulic Systems. Tehnicki Vjesnik - Technical Gazette, 25 (2). https://doi.org/10.17559/tv-20131209081056

- Taleyarkhan, R. P., West, C. D., Lahey, R. T., Nigmatulin, R. I., Block, R. C., Xu, Y. (2007). Erratum: Nuclear Emissions during Self-Nucleated Acoustic Cavitation [Phys. Rev. Lett.96, 034301 (2006)]. Physical Review Letters, 99 (26). https://doi.org/10.1103/physrevlett.99.269901

- Qian, J., Liu, C., Qiu, C., Li, W., Chen, D. (2024). Liquid hydrogen cavitation analysis inside an oblique globe valve. Flow Measurement and Instrumentation, 97, 102599. https://doi.org/10.1016/j.flowmeasinst.2024.102599

- Hwang, S., Kim, H., Choi, H., Kim, T., Kim, H. (2024). Design evaluation of an immersion heater using a fluid with low Prandtl number based on computation fluid dynamics analysis. Journal of Mechanical Science and Technology, 38 (4), 2151–2159. https://doi.org/10.1007/s12206-024-0343-2

- Nussupbekov, B., Oshanov, Y., Ovcharov, M., Duisenbayeva, M., Sharzadin, A., Kongyrbayeva, A., Amanzholova, M. (2024). The influence of the rotor shape on the efficiency of the hydrodynamic heater. Eastern-European Journal of Enterprise Technologies, 4 (8 (130)), 42–49. https://doi.org/10.15587/1729-4061.2024.310140

- Nussupbekov, B. R., Dyusenbayeva, M. S. (2023). Processing of organic waste by electrohydroimpulse method. Bulletin of the Karaganda University “Physics Series,” 111 (3), 156–162. https://doi.org/10.31489/2023ph3/156-162

- Kartbayeva, G., Duisenbayeva, M., Nussupbekov, B., Mussenova, E., Smagulov, Z., Kurmanaliev, A. (2024). Identification of the energy parameters of an electrohydroimpulse plant for the production of valuable components from organic raw materials. Eastern-European Journal of Enterprise Technologies, 3 (11 (129)), 6–13. https://doi.org/10.15587/1729-4061.2024.306787

- Duisenbayeva, M. S., Schrager, E. R., Sakipova, S. E., Nussupbekov, B. R. (2025). Study of optimal energy parameters of electro-hydropulse treatment for efficient extraction of valuable components from organic waste. Eurasian Physical Technical Journal, 22 (2 (52)), 54–59. https://doi.org/10.31489/2025n2/54-59

- Ved, V., Nikolsky, V., Oliynyk, O., Lipeev, A. (2017). Examining a cavitation heat generator and the control method over the efficiency of its operation. Eastern-European Journal of Enterprise Technologies, 4 (8 (88)), 22–28. https://doi.org/10.15587/1729-4061.2017.108580

- Baikadamova, A. M., Kakimov, A. K., Suychinov, A. K., Yessimbekov, Zh. S., Rakhymbay, D. (2023). Technology of processing cattle bones into meat and bone paste and the study of quality indicators. The Journal of Almaty Technological University, 1 (3), 14–18. https://doi.org/10.48184/2304-568x-2023-3-14-18

- Oraz, G. T., Ospanov, A. B., Chomanov, U. C., Kenenbay, G. S., Tursunov, A. A. (2019). Study of beef nutritional value of meat breed cattle of Kazakhstan. Journal of Hygienic Engineering and Design, 29, 99–105.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Bekbolat Nussupbekov, Мoldir Duisenbayeva, Yerlan Oshanov, Amangeldy Satybaldin, Raikhan Turlybekova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.