Devising an approach to calculating and optimizing a supersonic nozzle for cold gas-dynamic spraying

DOI:

https://doi.org/10.15587/1729-4061.2025.347028Keywords:

isentropic model, particle acceleration, multifactor optimization, critical speed, analysis of varianceAbstract

This work investigates the process of powder particle acceleration in a supersonic nozzle for cold gas-dynamic spraying (CGS). The task addressed in the study is predetermined by the lack of established patterns in the comprehensive influence of gas parameters and nozzle geometry on the speed of powder particles at the nozzle outlet, which complicates predicting and controlling the spraying process.

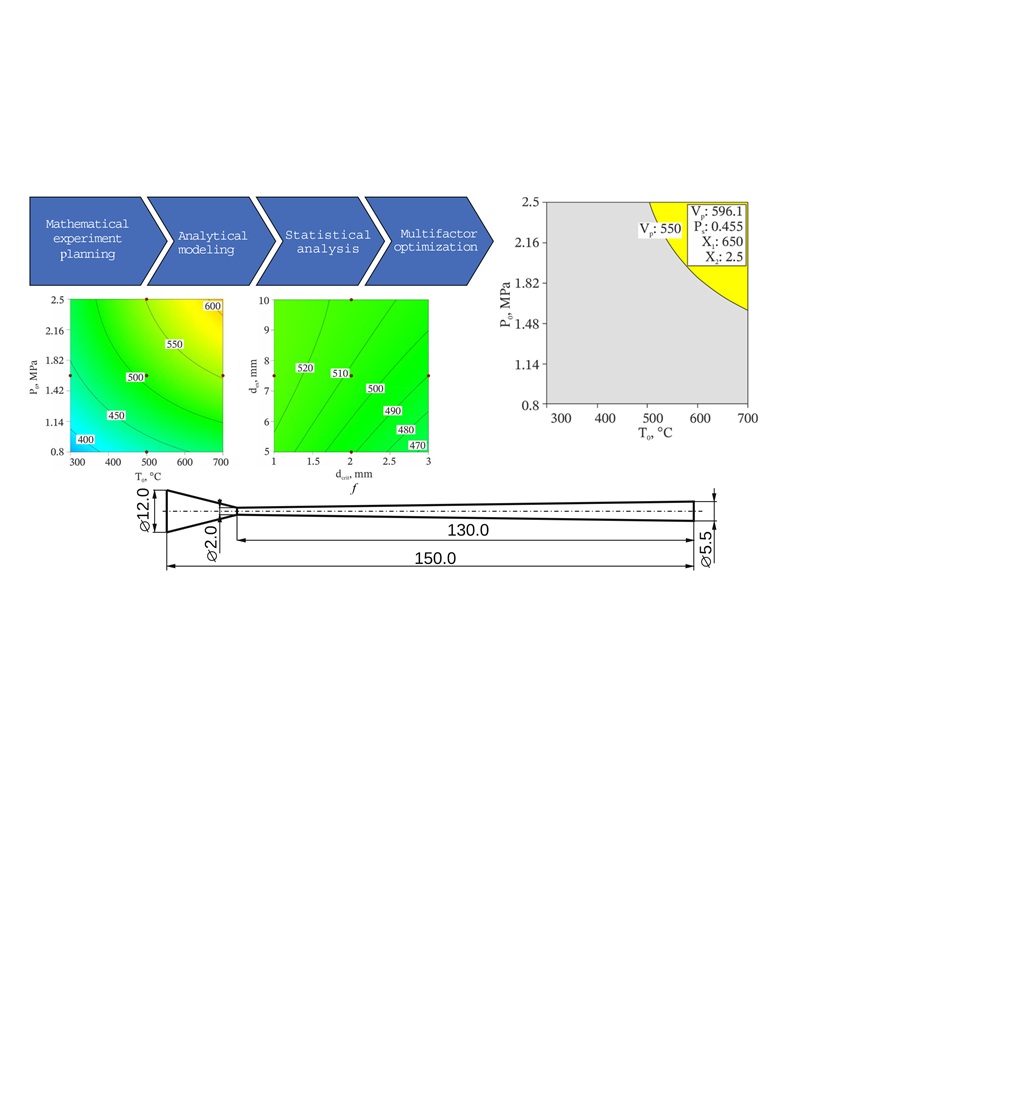

A new approach to the design of nozzles for CGS has been proposed and implemented, which allows for targeted optimization of their geometric parameters taking into account the gas parameters at the nozzle inlet. The approach is based on a combination of analytical modeling (isentropic model, particle acceleration model), methods of statistical planning and analysis of experiments (central compositional design, construction of regression equations), and multifactor optimization of nozzle geometry.

Regularities have been established between the velocity of aluminum particles with a size of 25 μm at the nozzle outlet and the gas parameters: stagnation pressure 0.8–2.5 MPa and stagnation temperature 300–700°C. The calculations also took into account the influence of the nozzle geometry: critical diameter 1.0–3.0 mm, outlet diameter 5.0–10.0 mm, length of the expansion section 80–150 mm. The resulting nozzle and spraying mode ensure that the particles achieve a velocity at the outlet of 596 m/s, which exceeds the required minimum of 550 m/s, at an air flow rate of 1.0 m3/min.

The proposed approach could be applied to designing new nozzles for mobile and stationary CGS installations operating on compressed air, nitrogen, or helium with a pressure of 0.6 to 4.0 MPa; in particular, for spraying protective and restorative coatings under conditions of limited gas flow. The results lay out the foundation for developing a software tool or an automated system for designing nozzles for CGS in a wide range of initial gas and powder parameters

References

- Champagne, V., Helfritch, D. (2015). Critical Assessment 11: Structural repairs by cold spray. Materials Science and Technology, 31 (6), 627–634. https://doi.org/10.1179/1743284714y.0000000723

- Li, W.-Y., Liao, H., Douchy, G., Coddet, C. (2007). Optimal design of a cold spray nozzle by numerical analysis of particle velocity and experimental validation with 316L stainless steel powder. Materials & Design, 28 (7), 2129–2137. https://doi.org/10.1016/j.matdes.2006.05.016

- Kun, T., Wenjie, H., Yurong, W. (2024). Optimization of Cold Spray Nozzles Based on the Response Surface Methodology. Journal of Engineering Sciences, 11 (1), F1–F11. https://doi.org/10.21272/jes.2024.11(1).f1

- Singhal, C., Murtaza, Q. (2024). Numerical optimization of cold gas dynamic spray process parameters through response surface methodology. Advances in Materials and Processing Technologies, 1–18. https://doi.org/10.1080/2374068x.2024.2439710

- Assadi, H., Gärtner, F., Stoltenhoff, T., Kreye, H. (2003). Bonding mechanism in cold gas spraying. Acta Materialia, 51 (15), 4379–4394. https://doi.org/10.1016/s1359-6454(03)00274-x

- Jadhav, P. A., Deivanathan, R. (2023). Numerical and experimental investigation of the droplet size for MQL aerosol under different operating parameters with Flow visualization. Engineering Research Express, 5 (3), 035069. https://doi.org/10.1088/2631-8695/acf548

- Shorinov, O., Dolmatov, A., Polyviany, S. (2023). The effect of process temperature and powder composition on microstructure and mechanical characteristics of low-pressure cold spraying aluminum-based coatings. Materials Research Express, 10 (2), 026401. https://doi.org/10.1088/2053-1591/acb6f0

- Shorinov, O., Volkov, A., Neveshkin, Y., Danko, K., Kalinichenko, N. (2023). Theoretical Study of Powder Particle Parameters in a Modified Cold Spray Nozzle. Advances in Design, Simulation and Manufacturing VI, 168–176. https://doi.org/10.1007/978-3-031-32774-2_17

- Sinnwell, Y., Maksakov, A., Palis, S., Antonyuk, S. (2025). Influence of the particle morphology on the spray characteristics in low-pressure cold gas process. Powder Technology, 464, 121084. https://doi.org/10.1016/j.powtec.2025.121084

- Klinkov, S., Kosarev, V., Shikalov, V., Vidyuk, T. (2023). Development of ejector nozzle for high-pressure cold spray application: a case study on copper coatings. The International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-023-11047-3

- Goyal, T., Walia, R. S., Sidhu, T. S. (2012). Multi-response optimization of low-pressure cold-sprayed coatings through Taguchi method and utility concept. The International Journal of Advanced Manufacturing Technology, 64 (5-8), 903–914. https://doi.org/10.1007/s00170-012-4049-8

- Shorinov, O. V., Polyviany, S. A. (2022). Simulation of Gas Flow with Nanocomposite Carbon-Containing Powders in Supersonic Nozzle. Metallofizika i Noveishie Tekhnologii, 44 (5), 601–611. https://doi.org/10.15407/mfint.44.05.0601

- Karkoulias, D. G., Tzoganis, E. D., Panagiotopoulos, A. G., Acheimastos, S.-G. D., Margaris, D. P. (2022). Computational Fluid Dynamics Study of Wing in Air Flow and Air–Solid Flow Using Three Different Meshing Techniques and Comparison with Experimental Results in Wind Tunnel. Computation, 10 (3), 34. https://doi.org/10.3390/computation10030034

- Benim, A. C., Diederich, M., Pfeiffelmann, B. (2018). Aerodynamic Optimization of Airfoil Profiles for Small Horizontal Axis Wind Turbines. Computation, 6 (2), 34. https://doi.org/10.3390/computation6020034

- Dykhuizen, R. C., Smith, M. F. (1998). Gas Dynamic Principles of Cold Spray. Journal of Thermal Spray Technology, 7 (2), 205–212. https://doi.org/10.1361/105996398770350945

- Grujicic, M., Zhao, C. L., Tong, C., DeRosset, W. S., Helfritch, D. (2004). Analysis of the impact velocity of powder particles in the cold-gas dynamic-spray process. Materials Science and Engineering: A, 368 (1-2), 222–230. https://doi.org/10.1016/j.msea.2003.10.312

- Maev, R., Leshchynsky, V. (2008). Introduction to Low Pressure Gas Dynamic Spray. Wiley‐VCH Verlag GmbH & Co. KGaA. https://doi.org/10.1002/9783527621903

- Ghajar, A. (2004). Compressible Flow. The Engineering Handbook, Second Edition. https://doi.org/10.1201/9781420039870.ch36

- Radulescu, L. F. (2018). A Concise Manual of Engineering Thermodynamics. World Scientific. https://doi.org/10.1142/11002

- Bharti, S., Dutta, V., Ghetiya, N. (2025). Optimization of friction stir processing parameters to produce AA2014/SiC surface composites using response surface methodology. Engineering Research Express, 7 (2), 025404. https://doi.org/10.1088/2631-8695/adc973

- Gabor, T., Akin, S., Jun, M. B.-G. (2024). Numerical studies on cold spray gas dynamics and powder flow in circular and rectangular nozzles. Journal of Manufacturing Processes, 114, 232–246. https://doi.org/10.1016/j.jmapro.2024.02.005

- Kamaraj, A., Zhou, W., Song, X. (2021). Computational Fluid Dynamics Simulation of Cold Spray Process for Particle Velocity Investigation. Proceedings of the 2nd International Conference on Advanced Surface Enhancement (INCASE 2021), 244–248. https://doi.org/10.1007/978-981-16-5763-4_54

- Wang, X., Yang, K., Zhou, W., Xia, Z. (2025). Numerical simulation study of nozzle flow field during cold spraying. Journal of Physics: Conference Series, 2951 (1), 012098. https://doi.org/10.1088/1742-6596/2951/1/012098

- Palodhi, L., Ray, P. K. (2024). Critical Velocity for Cold-Sprayed Coatings. Transactions of the Indian Institute of Metals, 77 (9), 2277–2291. https://doi.org/10.1007/s12666-024-03360-6

- Hu, W. J., Tan, K., Markovych, S., Liu, X. L. (2021). Study of a Cold Spray Nozzle Throat on Acceleration Characteristics via CFD. Journal of Engineering Sciences, 8 (1), F19–F24. https://doi.org/10.21272/jes.2021.8(1).f3

- Li, H., Le, Y., Xu, H., Li, Z. (2025). Design of the Dual-Path Cold Spray Nozzle to Improve Deposition Efficiency. Journal of Manufacturing and Materials Processing, 9 (5), 144. https://doi.org/10.3390/jmmp9050144

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksandr Shorinov, Nina Savchenko, Olga Shypul, Ihor Zorik, Serhii Nyzhnyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.