Identifying the variation of acid immersion and concrete cover on the crack width of reinforced concrete beams

DOI:

https://doi.org/10.15587/1729-4061.2025.347912Keywords:

acidic pH, reinforced concrete beams, concrete layers, crack widthAbstract

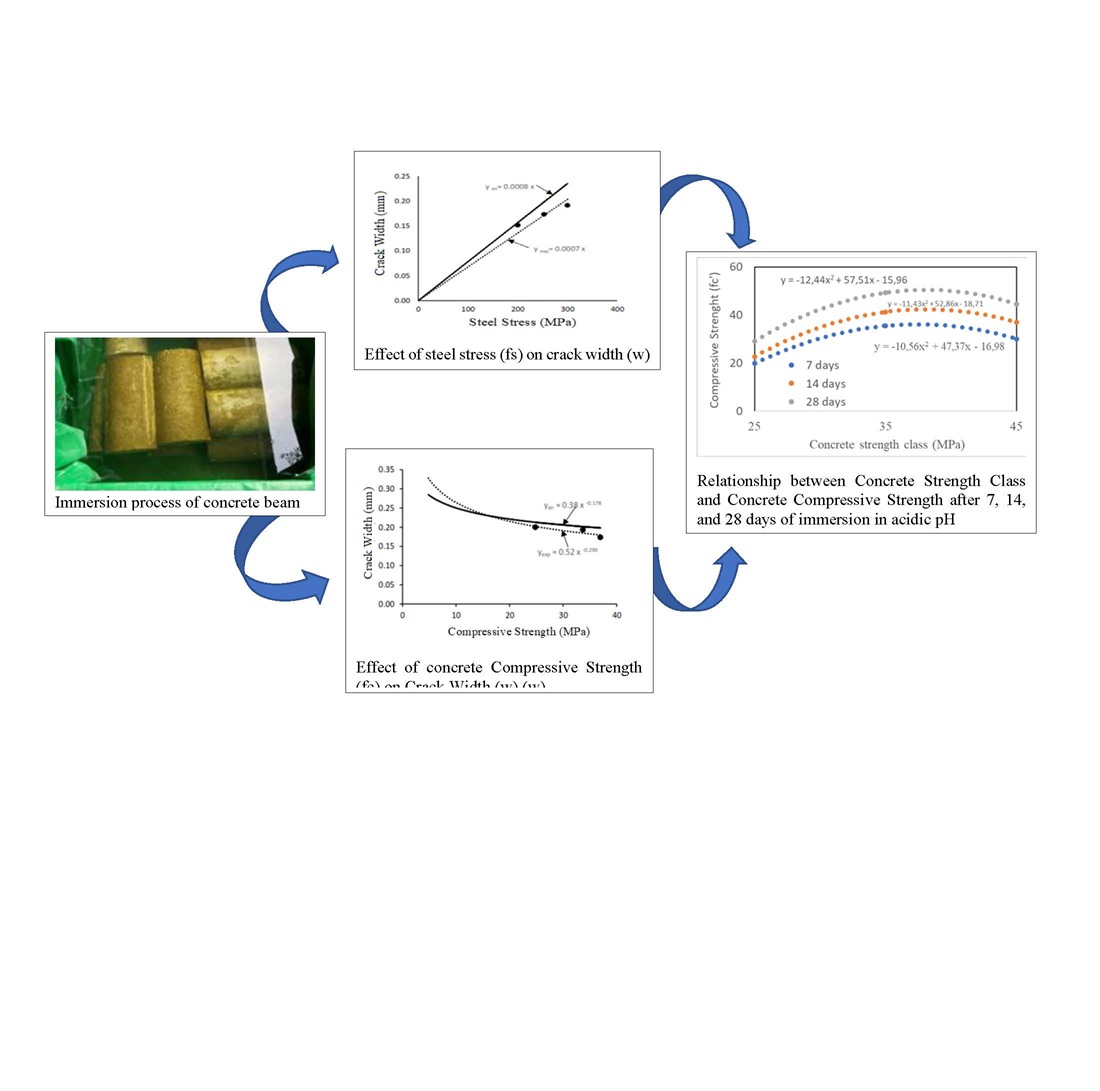

This paper discusses the effect of acidic environments on concrete structures, particularly crack width. This study was conducted to investigate the effect of acid ph on crack width in reinforced concrete beams with different cover depths. Reinforced concrete beams were immersed in phosphoric acid (H3PO4) solution with a pH of 5.0 for 28 days using this technique. Three concrete cover thicknesses were tested: 20 mm, 30 mm, and 40 mm. The materials used include coarse aggregate, fine aggregate, cement and phosphoric acid solution. Crack width, concrete compressive strength and steel stress were measured while the two-span beams with different section shapes experiencing point loads. The findings demonstrated that exposure of concrete to an acidic environment led to a decrease in compressive strength between 15% and 40%, cracking becoming significant with the beams having thin layers, while these results range a crack width ranging from no visible cracks until cracks resulted opened up. Crack width is directly dependent upon the thickness of concrete, for thicker concrete layer reducing crack width. On the other hand, steel stress increases crack width, with more the steel stress greater is crack wider. This study is unique in that an empirical formula related to crack width can be used for the prediction and has a good agreement with experimental results. The results yield new understanding on the significance of controlling concrete cover depth and steel stress level in the design methodologies for reinforced-concrete structures to be more acid-resisting. These findings may have implications for the design of reinforced concrete structures that are more resistant to acidic environmental conditions

References

- Pouya, J., Neji, M., De Windt, L., Perales, F., Socié, A. (2025). Effect of pre-crack on the degradation of cement pastes exposed to a low concentration external sulfate attack. Construction and Building Materials, 496, 143818. https://doi.org/10.1016/j.conbuildmat.2025.143818

- Mehdinazar, M., Kordani, A. A., Arabani, M. (2024). Effects of Changes in Runoff Characteristics on Asphalt Mixtures’ Performance Against Low-Temperature Cracking. Results in Engineering, 24, 103246. https://doi.org/10.1016/j.rineng.2024.103246

- Mayandi, K., Rajini, N., Ayrilmis, N., Indira Devi, M. P., Siengchin, S., Mohammad, F., Al-Lohedan, H. A. (2020). An overview of endurance and ageing performance under various environmental conditions of hybrid polymer composites. Journal of Materials Research and Technology, 9 (6), 15962–15988. https://doi.org/10.1016/j.jmrt.2020.11.031

- Suhudi, S., Frida S, K., Damayanti, F. (2024). Analysis of the Stability Plan for Kambaniru Weir, East Sumba District. Journal of Evrímata: Engineering and Physics, 02 (02), 138–143. https://doi.org/10.70822/journalofevrmata.v2i02.65

- Kanagaraj, B., Lubloy, E., Anand, N., Hlavicka, V., Kiran, T. (2023). Investigation of physical, chemical, mechanical, and microstructural properties of cement-less concrete – state-of-the-art review. Construction and Building Materials, 365, 130020. https://doi.org/10.1016/j.conbuildmat.2022.130020

- Deng, Y., Yang, Y. (2024). An Experimental Study on Corrosion Resistance and Bond Behavior of Reinforced Concrete Structures with Various Fibers. KSCE Journal of Civil Engineering, 28 (12), 5593–5603. https://doi.org/10.1007/s12205-024-1672-5

- Zhang, C., Chen, W., Zhu, H., An, R. (2025). Fatigue behavior and impedance spectrum characteristics of Cr-modified stainless-steel rebars after corrosion. Case Studies in Construction Materials, 23, e04964. https://doi.org/10.1016/j.cscm.2025.e04964

- XWang, X., Cao, H., Li, C., Wang, Y. (2025). Synergistic optimization of mechanical and corrosion resistance properties of epoxy resin modified with green synthetic silica/graphene nanoplatelets composite particles. Materials & Design, 258, 114634. https://doi.org/10.1016/j.matdes.2025.114634

- Keller, T., Zand, S. M., Habibi, T. (2025). Composite engineering structures in seawater − Review of durability and environmental performance. Composite Structures, 357, 118891. https://doi.org/10.1016/j.compstruct.2025.118891

- Standard specifications for concrete structures-2007, design (2010). JSCE Guidelines for Concrete No. 15. Tokyo: Japan Society of Civil Engineers. Available at: https://www.jsce-int.org/system/files/JGC15_Standard_Specifications_Design_1.0.pdf

- ACI 318: Building Code Requirements for Reinforced Concrete (1995). American Concrete Institute. Available at: https://archive.org/stream/gov.law.aci.318.1995/aci.318.1995_djvu.txt

- Thaue, W., Iwanami, M., Nakayama, K., Chijiwa, N. (2025). MICP using calcium-rich waste solution from acetic acid treatment as a calcium source to improve the properties of recycled coarse aggregate. Construction and Building Materials, 489, 142333. https://doi.org/10.1016/j.conbuildmat.2025.142333

- Risdanareni, P., Fatkhurrahman, Moch., Hastuti, A. A. M. B., Zai, K., Karolina, R., Mustafa, I., Kristiawan, S. A., Kusbiantoro, A. (2025). pH responsive natural-based hydrogel: Application in bacteria-based self-healing mortar. Results in Engineering, 28, 107932. https://doi.org/10.1016/j.rineng.2025.107932

- Azimi, N., Schollbach, K., Oliveira, D. V., Lourenço, P. B. (2024). Effect of acidic environment exposure on mechanical properties of TRM composites. Construction and Building Materials, 438, 137142. https://doi.org/10.1016/j.conbuildmat.2024.137142

- Abdulkadir, I., Mohammed, B. S., Woen, E. L., Sing, W. L., Al-Yacouby, A. M. (2024). Optimizing sulfate and acid resistance in rubberized engineered cementitious composite with graphene oxide-pretreated crumb rubber: A response surface methodology approach. Developments in the Built Environment, 18, 100405. https://doi.org/10.1016/j.dibe.2024.100405

- Koseoglu, S., Kubat, M., Uysal, M., Arslan Aydogdu, E. O., Aygun, B. F., Canpolat, O. (2025). Innovative gel method: Sustainable crack healing in ceramic powder geopolymer mortars via marine actinomycetes and bioactivated carriers. Case Studies in Construction Materials, 23, e04954. https://doi.org/10.1016/j.cscm.2025.e04954

- Suhudi, S., Damayanti, F. (2024). Stability Analysis of Retaining Soil Walls Protecting Banu Canal, Ngantru Village, Ngantang District, Malang-Indonesia. Journal of Evrímata: Engineering and Physics, 02 (01), 95–103. https://doi.org/10.70822/journalofevrmata.vi.37

- Li, X., Liang, X., Li, Z., Ye, Y. (2025). Preparation, microstructural characterization, and bio-corrosion resistance of novel high-performance marine concrete admixture. Case Studies in Construction Materials, 23, e05239. https://doi.org/10.1016/j.cscm.2025.e05239

- Li, X., Zhan, Q. W., Fu, C. H., Zhang, X., Zhao, Y. Q. (2025). Study on mechanism of concrete crack development control based on LDH and microbial carbon fixation mineralization. Case Studies in Construction Materials, 22, e04875. https://doi.org/10.1016/j.cscm.2025.e04875

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Faris Rizal Andardi, Agoes Soehardjono, Wisnumurti Wisnumurti, Ari Wibowo

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.