Determination of the structural features of joint material of the nitinol wires made by laser welding

DOI:

https://doi.org/10.15587/1729-4061.2025.348866Keywords:

superelasticity of the nitinol joint, laser welding, shape memory effect, intermetallics, eutecticAbstract

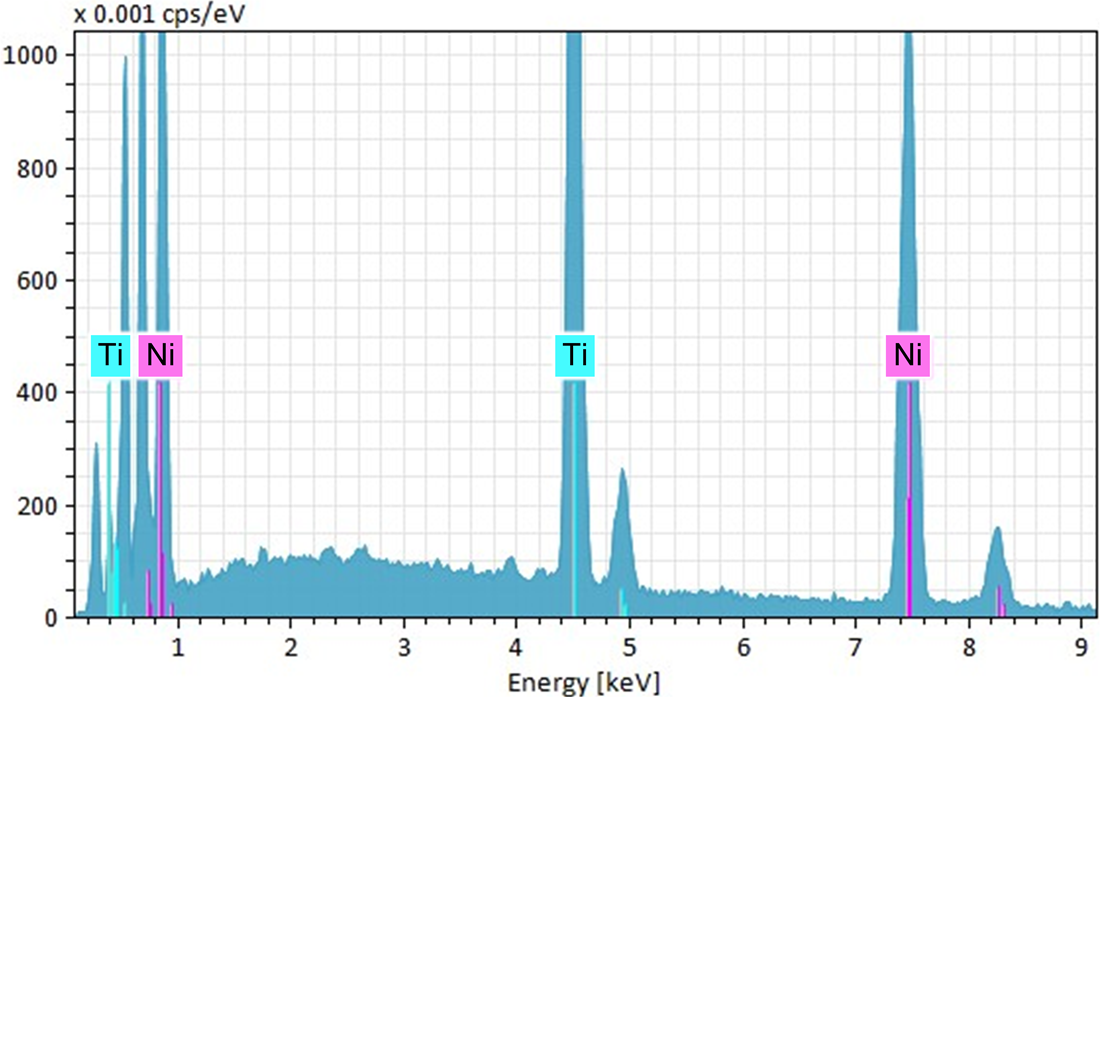

The object of the study is the welded joint of thin wires made of nitinol alloy. The problem of ensuring the formation of a joint of wires with a diameter of 0.8 mm made of nitinol alloy was solved based on determining the influence of laser welding modes on structural changes in the material of the weld. Based on the use of scanning electron microscopy, micro-X-ray spectral (EDS) analysis, a study of the properties of the material of the welded joint of the nitinol wires was performed. The joint was obtained by welding with an ytterbium fiber laser. It was confirmed that laser welding in an argon atmosphere is able to ensure the high-quality formation of a welded joint without macrodefects while maintaining the superelasticity of the joint material (within the shape memory effect). Two laser welding modes were used with a constant applied laser radiation energy. The duration of the laser radiation action and the multiplicity of such action were varied. At the same time, structural changes in the weld material, which are caused by the multiplicity of laser heating, involve the formation of enlarged zones of the eutectic TiNi + TiNi3 from metastable nanophases of titanium nickelides. The number of such grains decreases with the depth of the weld. Detection of structural changes and establishment of a decrease in the number of point phase inclusions with an increased nickel content in the weld can be a regulating factor for optimizing the structure of the welded joint material. In the welded joints made, when it is bent at an angle of 30°, the residual deformation does not exceed 10%. The results of the study of the structure of the welded joint of nitinol wires made by laser welding are promising and can be used in the conditions of manufacturing nitinol wire connections by welding medical products

References

- Otsuka, K., Wayman, C. M. (1998). Shape memory materials. Cambridge University Press, 284.

- Elahinia, M. H., Hashemi, M., Tabesh, M., Bhaduri, S. B. (2012). Manufacturing and processing of NiTi implants: A review. Progress in Materials Science, 57 (5), 911–946. https://doi.org/10.1016/j.pmatsci.2011.11.001

- Otsuka, K., Ren, X. (2005). Physical metallurgy of Ti–Ni-based shape memory alloys. Progress in Materials Science, 50 (5), 511–678. https://doi.org/10.1016/j.pmatsci.2004.10.001

- Shelyagin, V., Bernatskyi, A., Siora, O., Kedrovskyi, S., Koval, Yu., Slipchenko, V. et al. (2021). Laser Welding of Ti–Ni Shape Memory Alloy for Medical Application. Metallofizika i noveishie tekhnologii, 43 (3), 383–398. https://doi.org/10.15407/mfint.43.03.0383

- Mehrpouya, M., Gisario, A., Elahinia, M. (2018). Laser welding of NiTi shape memory alloy: A review. Journal of Manufacturing Processes, 31, 162–186. https://doi.org/10.1016/j.jmapro.2017.11.011

- Li, Q., Zhu, Y. (2018). Impact butt welding of NiTi and stainless steel- An examination of impact speed effect. Journal of Materials Processing Technology, 255, 434–442. https://doi.org/10.1016/j.jmatprotec.2017.12.046

- Prabu, S. S. M., Aravindan, S., Ghosh, S., Palani, I. A. (2023). Solid-state welding of nitinol shape memory alloys: A review. Materials Today Communications, 35, 105728. https://doi.org/10.1016/j.mtcomm.2023.105728

- Khalil-Allafi, J., Dlouhy, A., Eggeler, G. (2002). Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Materialia, 50 (17), 4255–4274. https://doi.org/10.1016/s1359-6454(02)00257-4

- Wagner, M. F.-X., Dey, S. R., Gugel, H., Frenzel, J., Somsen, Ch., Eggeler, G. (2010). Effect of low-temperature precipitation on the transformation characteristics of Ni-rich NiTi shape memory alloys during thermal cycling. Intermetallics, 18 (6), 1172–1179. https://doi.org/10.1016/j.intermet.2010.02.048

- Nishida, M., Wayman, C. M., Honma, T. (1986). Precipitation processes in near-equiatomic TiNi shape memory alloys. Metallurgical Transactions A, 17 (9), 1505–1515. https://doi.org/10.1007/bf02650086

- Khalil-Allafi, J., Eggeler, G., Dlouhy, A., Schmahl, W. W., Somsen, C. (2004). On the influence of heterogeneous precipitation on martensitic transformations in a Ni-rich NiTi shape memory alloy. Materials Science and Engineering: A, 378 (1-2), 148–151. https://doi.org/10.1016/j.msea.2003.10.335

- Cho, J. R., Lee, B. Y., Moon, Y. H., Van Tyne, C. J. (2004). Investigation of residual stress and post weld heat treatment of multi-pass welds by finite element method and experiments. Journal of Materials Processing Technology, 155-156, 1690–1695. https://doi.org/10.1016/j.jmatprotec.2004.04.325

- Krishnan, K. N. (2002). The effect of post weld heat treatment on the properties of 6061 friction stir welded joints. Journal of Materials Science, 37 (3), 473–480. https://doi.org/10.1023/a:1013701104029

- Elangovan, K., Balasubramanian, V. (2008). Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Materials Characterization, 59 (9), 1168–1177. https://doi.org/10.1016/j.matchar.2007.09.006

- ASTM F2063-18. Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants. https://doi.org/10.1520/f2063-18

- Oliveira, J. P., Braz Fernandes, F. M., Miranda, R. M., Schell, N. (2016). On the Mechanisms for Martensite Formation in YAG Laser Welded Austenitic NiTi. Shape Memory and Superelasticity, 2 (1), 114–120. https://doi.org/10.1007/s40830-016-0058-z

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Viktor Kvasnytskyi, Anastasiia Zvorykina, Leonid Zvorykin, Constantine Zvorykin, Valery Kostin, Tatjana Taranova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.