Determination of the resistance of building composites under different types of freezing

DOI:

https://doi.org/10.15587/1729-4061.2025.348938Keywords:

frost resistance of cement materials, durability of cement materials, material damage coefficient, climatic factorsAbstract

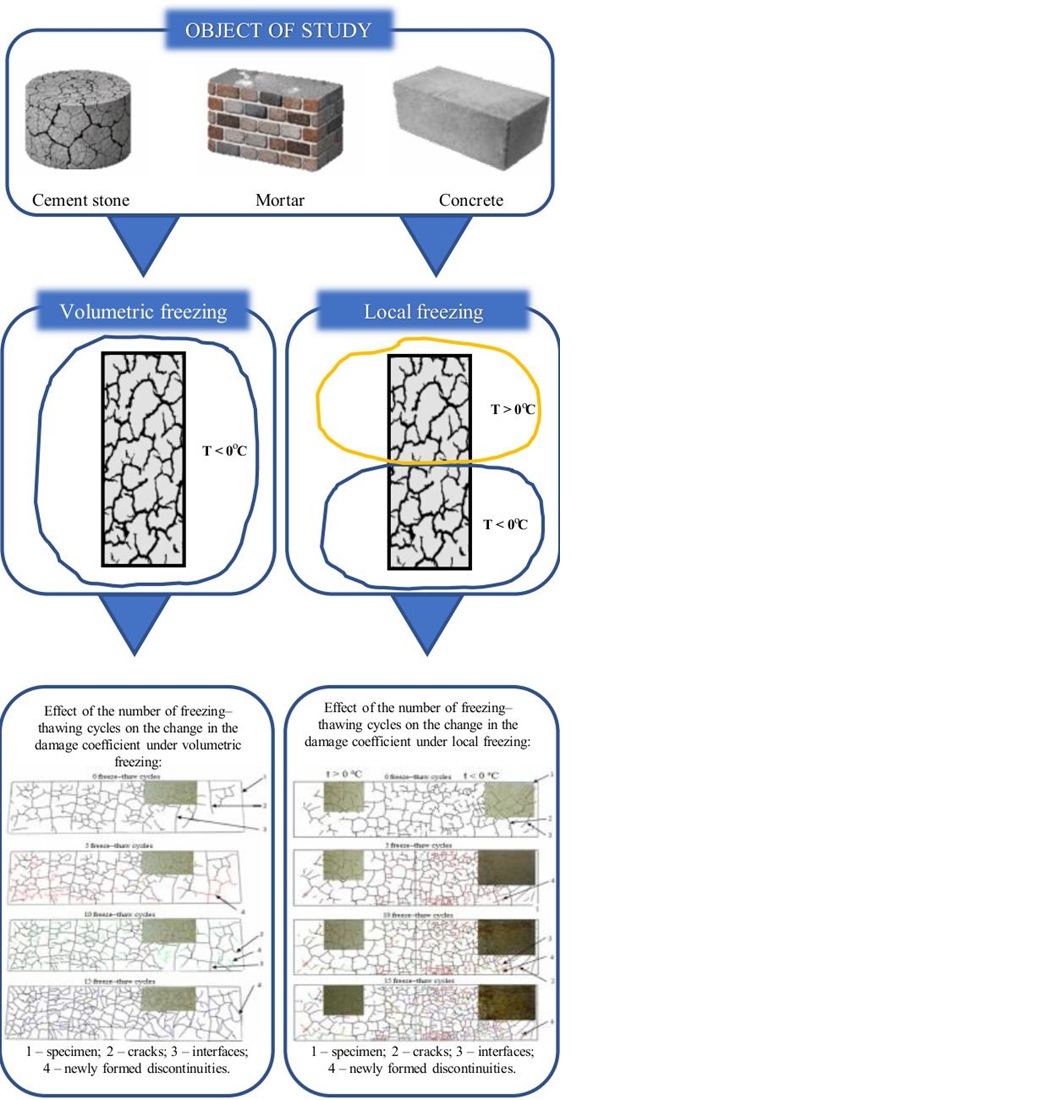

The object of the study is the processes of structural degradation and changes in the physico-mechanical properties of cement paste, cement–sand mortars, and concretes under cyclic freezing–thawing under different exposure conditions.

The problem considered in the study is the insufficient compliance of traditional methods for assessing frost resistance with real freezing conditions. Most structures in the natural environment are subjected to one-sided or local cooling, rather than comprehensive.

The article analyzed building composite materials: cement stone, mortars and concretes, as the object of the study. These materials are most often subjected to prolonged climatic influences during their operation.

The obtained experimental results give grounds to conclude that the conditions of exposure to negative temperatures on products and structures play a significant role in their ability to resist frost damage.

A comparison of different freezing conditions showed that with local exposure, the zone with higher humidity is destroyed more intensively. This indicates that traditional methods for assessing frost resistance, which are based only on comprehensive freezing, do not fully reflect the real operating conditions of structures.

Quantitatively, it was shown that after five freeze–thaw cycles, the damage coefficient under local exposure was about 30% higher than under uniform (all-sided) freezing.

The obtained results showed the need to develop recommendations for assessing the frost resistance of building materials depending on the operating conditions of the objects for which they are intended. Taking into account the identified dependencies in the current regulatory documents will allow for a more differentiated assignment of requirements for frost resistance of materials, which will inevitably lead to a decrease in the material intensity of products while simultaneously increasing the level of safe functioning. This is the practical significance of the research carried out.

The proposed approach allows for a more objective assessment of the frost resistance of building materials, which will contribute to increasing the durability of structures and reducing the material intensity of products without losing the level of their reliability

References

- Vyrovoy, V. N., Dorofeev, V. S., Suhanov, V. G. (2010). Kompozicionnye stroitelnye materialy i konstrukcii: struktura, samoorganizaciya, svoystva. Odessa: TES.

- Jodidio, P. (2018). Contemporary Concrete Buildings. Köln: Taschen, 632.

- Wang, R., Hu, Z., Li, Y., Wang, K., Zhang, H. (2022). Review on the deterioration and approaches to enhance the durability of concrete in the freeze–thaw environment. Construction and Building Materials, 321, 126371. https://doi.org/10.1016/j.conbuildmat.2022.126371

- Nikolaevich, N. A., Nikolaevich, V. V., Aleksaedrovich, C. A. (2021). Frost resistance of cement-sand and concrete beams during unilateral freezing. Croatian Regional Development Journal, 2 (1), 64–74. https://doi.org/10.2478/crdj-2021-0009

- Dvorkin, L. (2019). Design estimation of concrete frost resistance. Construction and Building Materials, 211, 779–784. https://doi.org/10.1016/j.conbuildmat.2019.03.108

- Yuan, J., Du, Z., Wu, Y., Xiao, F. (2019). Freezing-thawing resistance evaluations of concrete pavements with deicing salts based on various surfaces and air void parameters. Construction and Building Materials, 204, 317–326. https://doi.org/10.1016/j.conbuildmat.2019.01.149

- Koh, Y., Kamada, E. (1973). The influence of pore structure of concrete made with absorptive aggregates on the frost durability of concrete. Proceedings of the RILEM/IUPAC International Symposium, 'Pore Structure and Properties of Materials. Prague.

- Torrent, R. J., Neves, R. D., Imamoto, K. (2021). Concrete Permeability and Durability Performance. CRC Press. https://doi.org/10.1201/9780429505652

- Plugin, A., Miroshnichenko, S., Kalinin, O., Liakhu, L., Hanzhela, S. (2021). The crack resistance of reinforced-concrete sleepers’ with elastic rail fastening systems without base-plate. Experimental research. Collection of Scientific Works of the Ukrainian State University of Railway Transport, 192, 11–23. https://doi.org/10.18664/1994-7852.192.2021.223738

- Litvinenko, A. S. (2006). Issledovanie ciklichnosti pogodno-klimaticheskih usloviy Ukrainy v svyazi s prognozirovaniem vliyaniya opasnyh prirodnyh yavleniy na sostoyanie avtomobilnyh dorog. Dorohy i mosty, 5, 74–90.

- Dobshits, L. M. (2023). Physical and mathematical modeling of frost resistance for cement concretes. Structural Mechanics of Engineering Constructions and Buildings, 19 (3), 313–321. https://doi.org/10.22363/1815-5235-2023-19-3-313-321

- Liu, K., Yan, J., Hu, Q., Sun, Y., Zou, C. (2016). Effects of parent concrete and mixing method on the resistance to freezing and thawing of air-entrained recycled aggregate concrete. Construction and Building Materials, 106, 264–273. https://doi.org/10.1016/j.conbuildmat.2015.12.074

- Cortez, E. R., Durning, T. A., Jeknavorian, A. A., Korhonen, C. J. (1997). Antifreeze admixtures for concrete. Washington, DC: U.S. Department of Transportation. Available at: https://www.researchgate.net/publication/277858102_Antifreeze_Admixtures_for_Concrete

- Moore, M. R., Mughal, M. S., Papageorgiou, D. T. (2017). Ice formation within a thin film flowing over a flat plate. Journal of Fluid Mechanics, 817, 455–489. https://doi.org/10.1017/jfm.2017.100

- Powers, T. C. (1945). A Working Hypothesis for Further Studies of Frost Resistance of Concrete. ACI Journal Proceedings, 41 (1). https://doi.org/10.14359/8684

- Powers, T. C., Helmuth, R. A. (1953). Theory of volume changes in hardened Portland cement paste during freezing. Portland Cement Association.

- Beton według normy PN–EN 206–1 – komentarz. Krakow. Available at: https://ru.scribd.com/document/349401678/Beton-wg-PN-EN-206-1-pdf

- Vyrovoy, V., Sukhanov, V. (2019). Structural dynamic of building composites. Mechanics And Mathematical Methods, 1 (2), 27–35. https://doi.org/10.31650/2618-0650-2019-1-2-27-35

- Shtark, I., Viht, B. (2004). Dolgovechnost betona. Kyiv: Oranta, 295.

- DSTU B V.2.7-176:2008. Budivelni materialy. Sumishi betonni ta beton. Kyiv.

- DSTU EN 206:2022. Beton. Spetsyfikatsiya, produktyvnist, vyrobnytstvo ta vidpovidnist (EN 206:2013+A2:2021, IDT). Kyiv.

- DSTU B V.2.7-126:2011. Budivelni materialy. Sumishi budivelni sukhi modyfikovani. Zahalni tekhnichni umovy. Kyiv.

- DSTU B EN 197-1:2015. Tsement. Chastyna 1. Sklad, tekhnichni umovy ta kryteriyi vidpovidnosti dlia zvychainykh tsementiv (EN 197-1:2011, IDT). Kyiv.

- DSTU B V.2.7-187:2009. Budivelni materialy. Tsementy. Metody vyznachennia mitsnosti na zghyn i stysk. Kyiv.

- DSTU EN 12390-3:2024. Vyprobuvannia betonu. Chastyna 3. Mitsnist zrazkiv na stysk (EN 12390-3:2019, IDT). Kyiv.

- DSTU EN 12390-5:2025. Vyprobuvannia betonu. Chastyna 5. Mitsnist zrazkiv na roztiah za zghynu (EN 12390-5:2019, IDT). Kyiv.

- DSTU EN 12390-6:2025. Vyprobuvannia betonu. Chastyna 6. Mitsnist zrazkiv na roztiah za rozkoliuvannia (EN 12390-6:2009, IDT). Kyiv.

- DSTU B V.2.7-170:2008. Budivelni materialy. Betony. Metody vyznachennia serednoi hustyny, volohosti, vodopohlynannia, porystosti i vodonepronyknosti. Kyiv.

- DSTU EN 12504-4:2022. Vyprobuvannia betonu v konstruktsiyakh. Chastyna 4. Vyznachennia shvydkosti ultrazvukovoho impulsu (EN 12504-4:2021, IDT). Kyiv.

- Nepomnyashchy, A. N., Vyrovoy, V. N. (2016). Analysis of methods quantifying damage of material construction. Visnyk Odeskoi derzhavnoi akademiyi budivnytstva ta arkhitektury, 63, 174–178. Available at: http://nbuv.gov.ua/UJRN/Vodaba_2016_63_31

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksandr Nepomiashchiy, Valeriy Vyrovoy, Vitalii Shevchenko, Marina Kotikova, Dmytro Taichan

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.