Damage formations of ramie fiber composites multilayer armour system under high-velocity impacts

DOI:

https://doi.org/10.15587/1729-4061.2023.273788Keywords:

multilayer armour system, wolfram carbide, ramie fiber, back face signatureAbstract

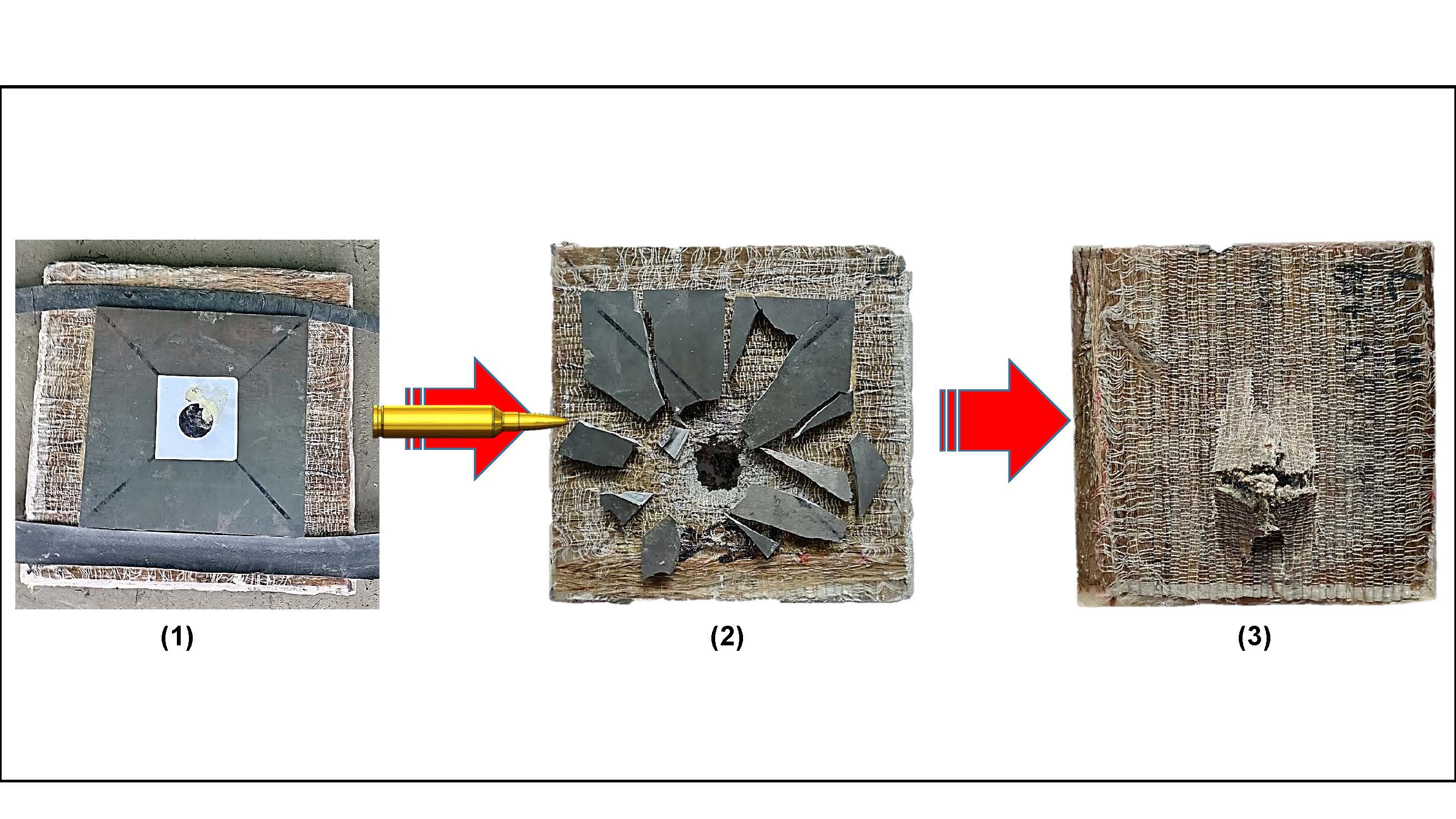

Multilayer armour system (MAS) becomes the best choice in reinforcing protection for military officers against projectile attack which has a high velocity of up to 7.62×51 mm NATO ball lead core (projectile level III NIJ standard) or AP 7.62×51 mm hard steel core (projectile level IV NIJ standard). This study aimed to analyze the damage formation of wolfram carbide (WC) ceramic and ramie fiber composites. The frontmost MAS uses WC ceramic and is enveloped by a back layer of ramie fiber composites with epoxy resin reinforcing material as the matrix. Ballistic testing was carried out in this study using a long-barreled rifle to determine the resistance of the MAS from projectile impact. The speed meter in ballistic testing uses a velocity sensor type light screen B 471 and clay witness is used to measure back face signature (BFS). The results show that 7.62 lead core and hard steel core projectiles were unable to penetrate the 3-layer ceramic MAS in the front. The results are marked by a relatively low BFS value of 1.45 and 1.17 mm, so that the energy in the MAS with 3 ceramic layer is absorbed efficiently but with the phenomenon of rupture ceramic failure. Ceramic rupture failure needs to be overcome by bonding several layers of ramie so that MAS can be used in the next stage. MAS with 1 and 2 ceramic layers are unable to withstand projectile level III and level IV NIJ standard. From these results it is known that the MAS limit can withstand the projectile level III and IV NIJ standard, namely MAS with 3 ceramic layers. The damage formation of ceramic was rupturing ceramic failure. Therefore, it is necessary to design a ceramic binder by placing some ramie fibers in front of the ceramic

Supporting Agency

- The authors are grateful for the financial support by the Directorate of Research and Community Service, Deputy for Strengthening Research and Development, Ministry of Research, Technology/National Research and Innovation Agency of the Republic of Indonesia, and Konsorsium Ramie Indonesia (KORI). The authors would also like to express their utmost gratitude to the Research and Development Department of the Indonesian Army for their supports and contributions that ensure this study proceeded smoothly.

References

- Nurhadiyanto, D., Mujiyono, Mukhammad, A. F. H., Setyoko, M. B., bin Yahya, M. Y., Riyadi, T. W. B. (2021). Drop test resistance on ramie fiber bulletproof panels based on harvest time and fiber treatment of ramie. Composites: Mechanics, Computations, Applications: An International Journal, 12 (1), 1–16. doi: https://doi.org/10.1615/compmechcomputapplintj.2020035788

- Grujicic, M., Pandurangan, B., d’Entremont, B. (2012). The role of adhesive in the ballistic/structural performance of ceramic/polymer–matrix composite hybrid armor. Materials & Design, 41, 380–393. doi: https://doi.org/10.1016/j.matdes.2012.05.023

- Serjouei, A., Chi, R., Zhang, Z., Sridhar, I. (2015). Experimental validation of BLV model on bi-layer ceramic-metal armor. International Journal of Impact Engineering, 77, 30–41. doi: https://doi.org/10.1016/j.ijimpeng.2014.11.001

- Akella, K., Naik, N. K. (2015). Composite Armour – A Review. Journal of the Indian Institute of Science, 95 (3), 297–312. Available at: http://journal.library.iisc.ernet.in/index.php/iisc/article/view/4574/4871

- Medvedovski, E. (2010). Ballistic performance of armour ceramics: Influence of design and structure. Part 1. Ceramics International, 36 (7), 2103–2115. doi: https://doi.org/10.1016/j.ceramint.2010.05.021

- Tasdemirci, A., Tunusoglu, G., Güden, M. (2012). The effect of the interlayer on the ballistic performance of ceramic/composite armors: Experimental and numerical study. International Journal of Impact Engineering, 44, 1–9. doi: https://doi.org/10.1016/j.ijimpeng.2011.12.005

- Tabiei, A., Nilakantan, G. (2008). Ballistic Impact of Dry Woven Fabric Composites: A Review. Applied Mechanics Reviews, 61 (1). doi: https://doi.org/10.1115/1.2821711

- Cheeseman, B. A., Bogetti, T. A. (2003). Ballistic impact into fabric and compliant composite laminates. Composite Structures, 61 (1-2), 161–173. doi: https://doi.org/10.1016/s0263-8223(03)00029-1

- Kumar, S., Malek, A., Babu, R., Mathur, S. (2021). Ballistic Efficiency of Multilayered Armor System Reinforced with Jute-Kevlar Epoxy Composite against High-Energy Steel Core Projectile. Journal of Materials Engineering and Performance, 30 (11), 8447–8464. doi: https://doi.org/10.1007/s11665-021-06057-9

- Cruz, R. B. da, Lima Junior, E. P., Monteiro, S. N., Louro, L. H. L. (2015). Giant Bamboo Fiber Reinforced Epoxy Composite in Multilayered Ballistic Armor. Materials Research, 18 (suppl 2), 70–75. doi: https://doi.org/10.1590/1516-1439.347514

- Luz, F. S. da, Lima Junior, E. P., Louro, L. H. L., Monteiro, S. N. (2015). Ballistic Test of Multilayered Armor with Intermediate Epoxy Composite Reinforced with Jute Fabric. Materials Research, 18 (suppl 2), 170–177. doi: https://doi.org/10.1590/1516-1439.358914

- Braga, F. de O., Bolzan, L. T., Ramos, F. J. H. T. V., Monteiro, S. N., Lima Jr., É. P., Silva, L. C. da. (2018). Ballistic Efficiency of Multilayered Armor Systems with Sisal Fiber Polyester Composites. Materials Research, 20 (suppl 2), 767–774. doi: https://doi.org/10.1590/1980-5373-mr-2017-1002

- Braga, F. de O., Bolzan, L. T., Lima Jr., É. P., Monteiro, S. N. (2017). Performance of natural curaua fiber-reinforced polyester composites under 7.62 mm bullet impact as a stand-alone ballistic armor. Journal of Materials Research and Technology, 6 (4), 323–328. doi: https://doi.org/10.1016/j.jmrt.2017.08.003

- Monteiro, S., Pereira, A., Ferreira, C., Pereira Júnior, É., Weber, R., Assis, F. (2018). Performance of Plain Woven Jute Fabric-Reinforced Polyester Matrix Composite in Multilayered Ballistic System. Polymers, 10 (3), 230. doi: https://doi.org/10.3390/polym10030230

- Wambua, P., Vangrimde, B., Lomov, S., Verpoest, I. (2007). The response of natural fibre composites to ballistic impact by fragment simulating projectiles. Composite Structures, 77 (2), 232–240. doi: https://doi.org/10.1016/j.compstruct.2005.07.006

- Kumar, A. P., Singh, R. P., Sarwade, B. D. (2005). Degradability of composites, prepared from ethylene–propylene copolymer and jute fiber under accelerated aging and biotic environments. Materials Chemistry and Physics, 92 (2-3), 458–469. doi: https://doi.org/10.1016/j.matchemphys.2005.01.027

- Soykeabkaew, N., Supaphol, P., Rujiravanit, R. (2004). Preparation and characterization of jute- and flax-reinforced starch-based composite foams. Carbohydrate Polymers, 58 (1), 53–63. doi: https://doi.org/10.1016/j.carbpol.2004.06.037

- Mohammed, L., Ansari, M. N. M., Pua, G., Jawaid, M., Islam, M. S. (2015). A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. International Journal of Polymer Science, 2015, 1–15. doi: https://doi.org/10.1155/2015/243947

- Monteiro, S. N., Milanezi, T. L., Louro, L. H. L., Lima, É. P., Braga, F. O., Gomes, A. V., Drelich, J. W. (2016). Novel ballistic ramie fabric composite competing with Kevlar™ fabric in multilayered armor. Materials & Design, 96, 263–269. doi: https://doi.org/10.1016/j.matdes.2016.02.024

- Rajole, S., Ravishankar, K. S., Kulkarni, S. M. (2020). Performance study of jute-epoxy composites/sandwiches under normal ballistic impact. Defence Technology, 16 (4), 947–955. doi: https://doi.org/10.1016/j.dt.2019.11.011

- Mohanty, A. K., Khan, M. A., Hinrichsen, G. (2000). Influence of chemical surface modification on the properties of biodegradable jute fabrics – polyester amide composites. Composites Part A: Applied Science and Manufacturing, 31 (2), 143–150. doi: https://doi.org/10.1016/s1359-835x(99)00057-3

- Subhi, K. A., Hussein, E. K., Al-Hamadani, H. R. D., Sharaf, H. K. (2022). Investigation of the mechanical performance of the composite prosthetic keel based on the static load: a computational analysis. Eastern-European Journal of Enterprise Technologies, 3 (7 (117)), 22–30. doi: https://doi.org/10.15587/1729-4061.2022.256943

- Kumar, S., Akella, K., Joshi, M., Tewari, A., Naik, N. K. (2020). Performance of Ceramic-Composite Armors under Ballistic Impact Loading. Journal of Materials Engineering and Performance, 29 (9), 5625–5637. doi: https://doi.org/10.1007/s11665-020-05041-z

- Mujiyono, Nurhadiyanto, D., Mukhammad, A. F. H. (2017). Ramie Fiber Reinforced Epoxy (RFRE) Composite for Bulletproof Panels. J. Fundam. Appl. Sci., 9 (7S), 228–240. Available at: https://www.ajol.info/index.php/jfas/article/view/168564

- Shakil, U. A., Abu Hassan, S. B., Yahya, M. Y., Mujiyono, Nurhadiyanto, D. (2021). A review of properties and fabrication techniques of fiber reinforced polymer nanocomposites subjected to simulated accidental ballistic impact. Thin-Walled Structures, 158, 107150. doi: https://doi.org/10.1016/j.tws.2020.107150

- Pangestu, T. P., Ahmad, W. A., Bawono, A. S., Aqifd, M. (2020). The performance of stability test using Bantak aggregate and AC50/70 as polymer on Marshall characteristic. Journal of Engineering and Applied Technology, 1 (2), 97–109. doi: https://doi.org/10.21831/jeatech.v1i2.39232

- Mukasey, M. B., Sedgwick, J. L., Hagy, D. W. (2008). Ballistic Resistance of Body Armor. NIJ Standard-0101.06. Available at: https://www.nist.gov/system/files/documents/oles/ballistic.pdf

- Flores-Johnson, E. A., Saleh, M., Edwards, L. (2011). Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile. International Journal of Impact Engineering, 38 (12), 1022–1032. doi: https://doi.org/10.1016/j.ijimpeng.2011.08.005

- Salient features of Indian Standard on Bullet resistant jackets (IS 17051:2018). Available at: https://ficci.in/events/24084/ISP/BRJ.pdf

- Nascimento, L. F. C., Louro, L. H. L., Monteiro, S. N., Gomes, A. V., Marçal, R. L. S. B., Lima Júnior, É. P., Margem, J. I. (2017). Ballistic Performance of Mallow and Jute Natural Fabrics Reinforced Epoxy Composites in Multilayered Armor. Materials Research, 20 (suppl 2), 399–403. doi: https://doi.org/10.1590/1980-5373-mr-2016-0927

- Garcia Filho, F. D. C., Oliveira, M. S., Pereira, A. C., Nascimento, L. F. C., Ricardo Gomes Matheus, J., Monteiro, S. N. (2020). Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. Journal of Materials Research and Technology, 9 (2), 1734–1741. doi: https://doi.org/10.1016/j.jmrt.2019.12.004

- Hu, D., Wang, J., Yin, L., Chen, Z., Yi, R., Lu, C. (2017). Experimental study on the penetration effect of ceramics composite projectile on ceramic / A3 steel compound targets. Defence Technology, 13 (4), 281–287. doi: https://doi.org/10.1016/j.dt.2017.05.011

- Monteiro, S. N., Lima, É. P., Louro, L. H. L., da Silva, L. C., Drelich, J. W. (2014). Unlocking Function of Aramid Fibers in Multilayered Ballistic Armor. Metallurgical and Materials Transactions A, 46 (1), 37–40. doi: https://doi.org/10.1007/s11661-014-2678-2

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Mujiyono, Didik Nurhadiyanto, Alaya Fadllu Hadi Mukhammad, Tri Widodo Besar Riyadi, Kristanto Wahyudi, Nur Kholis, Asri Peni Wulandari, Shukur bin Abu Hassan

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.