Удосконалення технології створення чутливих газових сенсорів на основі оксиду цинку при використанні методу магнітронного розпилення на постійному струмі

DOI:

https://doi.org/10.15587/1729-4061.2023.277428Ключові слова:

оксид цинку, газовий сенсор, магнітронне розпилення, реакція чутливості, цільовий газАнотація

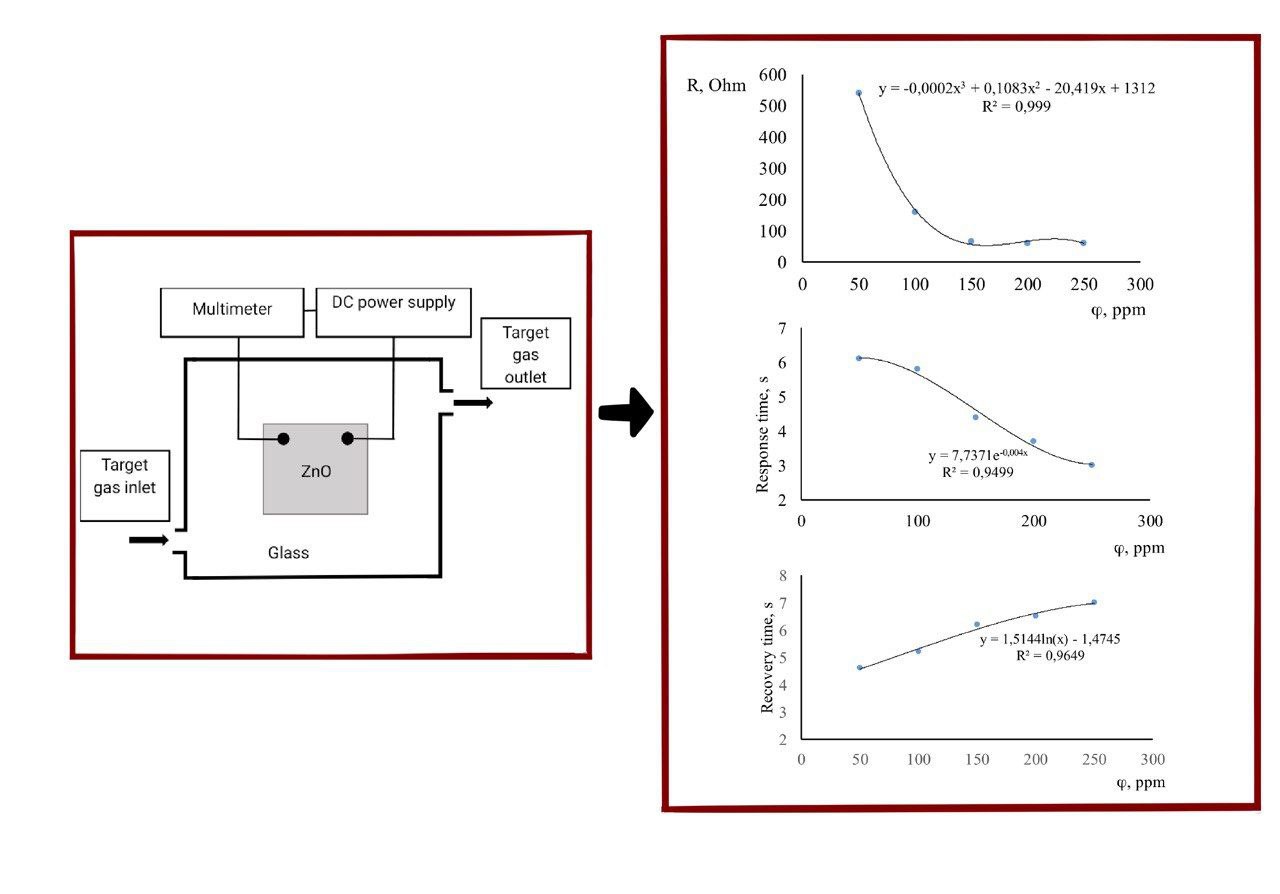

Досліджено газовий сенсор на основі оксиду цинку отриманий методом магнетронного розпилення на постійному струмі. Відомі методи осадження наноструктур оксиду цинку, такі як термічне випаровування, хімічне осадження з парової фази, металоорганічне хімічне осадження з парової фази, магнетронне розпилення, імпульсне лазерне осадження та гідротермальний процес. Найменьш дослідженим є магнетронне розпилення. Для одержання плівок використовували вакуумну установку ВУП-5М з оригінальним матеріалозберігаючим магнітроном. Проведені досліження чутливості та швидкодії газового сенсору на основі ZnO до цільового газу – етанолу різних концентрацій. Отримані експериментальні залежності чутливості газового сенсору від концентрації цільового газу демонструють, що зі збільшенням концентрації цільового газу опір зменшувався, а чутливість зразка збільшувалася. Встановлено, що зміна опору досліджуваного зразка пропорційна зміні концентрації цільового газу. Після того, як поверхня сенсору стає насиченою адсорбованими молекулами, опір більше не зменшується, навіть якщо концентрація газу продовжує зростати. Реакція газового сенсору на цільовий газ – етанол при концентрації вище 150 ppm була майже відсутня. Час, необхідний для досягнення максимального значення відгуку, має бути нижчим при вищих цільових концентраціях газу. Дослідження повторюваності реакції чутливості були проведені вимірювання опору газового сенсору на основі ZnO в атмосфері цільового газу з концентрацієй 150 ppm. Встановлено, що газовий сенсор демострує чудову стабільність і послідовну реакцію чутливості при повторному впливі цільового газу – етанолу. Встановлено, що час реакції газового сенсору на основі ZnO на цільовий газ при кожному повторному впливі не перевищує 10 с. Такий показник повторюваності дозволяє стверджувати про стабільність роботи газового сенсору на основі ZnO в атмосфері етанолу за стандартних умов

Посилання

- Vambol, S., Vambol, V., Sychikova, Y., Deyneko, N. (2017). Analysis of the ways to provide ecological safety for the products of nanotechnologies throughout their life cycle. Eastern-European Journal of Enterprise Technologies, 1 (10 (85)), 27–36. doi: https://doi.org/10.15587/1729-4061.2017.85847

- Semko, A., Rusanova, O., Kazak, O., Beskrovnaya, M., Vinogradov, S., Gricina, I. (2015). The use of pulsed high-speed liquid jet for putting out gas blow-out. The International Journal of Multiphysics, 9 (1), 9–20. doi: https://doi.org/10.1260/1750-9548.9.1.9

- Popov, O., Іatsyshyn, A., Kovach, V., Artemchuk, V., Taraduda, D., Sobyna, V. et al. (2018). Conceptual Approaches for Development of Informational and Analytical Expert System for Assessing the NPP impact on the Environment. Nuclear and Radiation Safety, 3 (79), 56–65. doi: https://doi.org/10.32918/nrs.2018.3(79).09

- Dubinin, D., Korytchenko, K., Lisnyak, A., Hrytsyna, I., Trigub, V. (2017). Numerical simulation of the creation of a fire fighting barrier using an explosion of a combustible charge. Eastern-European Journal of Enterprise Technologies, 6 (10 (90)), 11–16. doi: https://doi.org/10.15587/1729-4061.2017.114504

- Popov, O., Iatsyshyn, A., Kovach, V., Artemchuk, V., Taraduda, D., Sobyna, V. et al. (2019). Physical Features of Pollutants Spread in the Air During the Emergency at NPPs. Nuclear and Radiation Safety, 4 (84), 88–98. doi: https://doi.org/10.32918/nrs.2019.4(84).11

- Kondratenko, O., Vambol, S., Strokov, O., Avramenko, A. (2015). Mathematical model of the efficiency of diesel particulate matter filter. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 6, 55–61.

- Deyneko, N., Yeremenko, S., Kamyshentsev, G., Kryvulkin, I., Matiushenko, M., Myroshnyk, O. et al. (2021). Development of a method for obtaining a CdS/CdTe/Cu/Au module on a flexible substrate designed for backup supplying systems prevention of emergency situations. Eastern-European Journal of Enterprise Technologies, 1 (5 (109)), 31–36. doi: https://doi.org/10.15587/1729-4061.2021.225694

- Neshpor, O., Deyneko, N., Ponomarenko, R., Maiboroda, A., Kropyva, M., Blyashenko, O. et al. (2022). Optimization of the technology for designing sensitive gas sensors based on zinc oxide using a sol-gel method. Eastern-European Journal of Enterprise Technologies, 4 (5 (118)), 30–36. doi: https://doi.org/10.15587/1729-4061.2022.263686

- Wales, D. J., Grand, J., Ting, V. P., Burke, R. D., Edler, K. J., Bowen, C. R. et al. (2015). Gas sensing using porous materials for automotive applications. Chemical Society Reviews, 44 (13), 4290–4321. doi: https://doi.org/10.1039/c5cs00040h

- Wetchakun, K., Samerjai, T., Tamaekong, N., Liewhiran, C., Siriwong, C., Kruefu, V. et al. (2011). Semiconducting metal oxides as sensors for environmentally hazardous gases. Sensors and Actuators B: Chemical, 160 (1), 580–591. doi: https://doi.org/10.1016/j.snb.2011.08.032

- Zhang, Y., Li, D., Qin, L., Zhao, P., Liu, F., Chuai, X. et al. (2018). Preparation and gas sensing properties of hierarchical leaf-like SnO2 materials. Sensors and Actuators B: Chemical, 255, 2944–2951. doi: https://doi.org/10.1016/j.snb.2017.09.115

- Nunes, D., Pimentel, A., Santos, L., Barquinha, P., Pereira, L., Fortunato, E., Martins, R. (2019). Synthesis, design, and morphology of metal oxide nanostructures. Metal Oxide Nanostructures, 21–57. doi: https://doi.org/10.1016/b978-0-12-811512-1.00002-3

- Saboor, A., Shah, S. M., Hussain, H. (2019). Band gap tuning and applications of ZnO nanorods in hybrid solar cell: Ag-doped verses Nd-doped ZnO nanorods. Materials Science in Semiconductor Processing, 93, 215–225. doi: https://doi.org/10.1016/j.mssp.2019.01.009

- Shaikh, S. K., Ganbavale, V. V., Mohite, S. V., Patil, U. M., Rajpure, K. Y. (2018). ZnO nanorod based highly selective visible blind ultra-violet photodetector and highly sensitive NO2 gas sensor. Superlattices and Microstructures, 120, 170–186. doi: https://doi.org/10.1016/j.spmi.2018.05.021

- Kumar, M., Singh Bhati, V., Ranwa, S., Singh, J., kumar, M. (2017). Pd/ZnO nanorods based sensor for highly selective detection of extremely low concentration hydrogen. Scientific Reports, 7 (1). doi: https://doi.org/10.1038/s41598-017-00362-x

- Jing, Z., Zhan, J. (2008). Fabrication and Gas-Sensing Properties of Porous ZnO Nanoplates. Advanced Materials, 20 (23), 4547–4551. doi: https://doi.org/10.1002/adma.200800243

- Jabeen, M., Iqbal, A., Kumar, R. V., Ahmed, M. (2019). Pd-doped zinc oxide nanostructures for liquefied petroleum gas detection at low temperature. Sensing and Bio-Sensing Research, 25, 100293. doi: https://doi.org/10.1016/j.sbsr.2019.100293

- Patial, P., Deshwal, M. (2022). A platinum-doped ZnO-based LPG sensor with high sensitivity. Materials Today: Proceedings, 48, 1201–1204. doi: https://doi.org/10.1016/j.matpr.2021.08.245

- Deng, X., Sang, S., Li, P., Li, G., Gao, F., Sun, Y. et al. (2013). Preparation, Characterization, and Mechanistic Understanding of Pd-Decorated ZnO Nanowires for Ethanol Sensing. Journal of Nanomaterials, 2013, 1–8. doi: https://doi.org/10.1155/2013/297676

- Roy, S., Banerjee, N., Sarkar, C. K., Bhattacharyya, P. (2013). Development of an ethanol sensor based on CBD grown ZnO nanorods. Solid-State Electronics, 87, 43–50. doi: https://doi.org/10.1016/j.sse.2013.05.003

- Aldosary, A. F., Shar, M. A., AlQahtani, H. R. (2022). High-sensitivity detection of ethane and ethylene using gamma-irradiated ZnO chemiresistors. Measurement: Sensors, 24, 100600. doi: https://doi.org/10.1016/j.measen.2022.100600

- Choopun, S., Hongsith, N., Mangkorntong, P., Mangkorntong, N. (2007). Zinc oxide nanobelts by RF sputtering for ethanol sensor. Physica E: Low-Dimensional Systems and Nanostructures, 39 (1), 53–56. doi: https://doi.org/10.1016/j.physe.2006.12.053

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Alona Miasoiedova, Natalia Minska, Roman Shevchenko, Olena Azarenkо, Viktoriia Lukashenko, Oksana Kyrychenko, Oleh Zemlianskyi, Larisa Trefilova, Gennady Kamyshentsev, Roman Melezhyk

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.