Identifying the influence of technological factors on the structure and properties of contact wire from secondary copper

DOI:

https://doi.org/10.15587/1729-4061.2023.282697Keywords:

copper contact wire, electrical resistance of continuously cast copper blanks, copper modificationAbstract

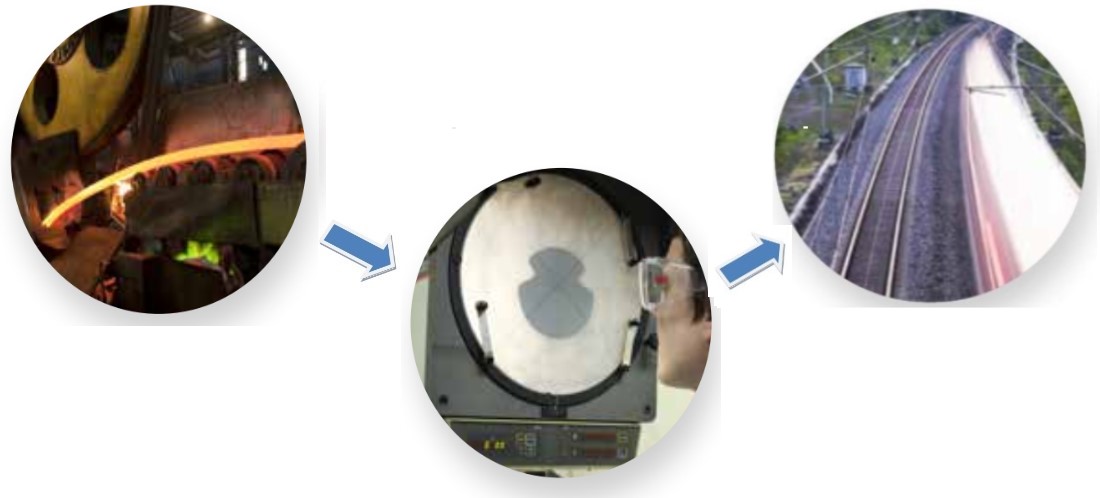

This paper reports the analysis of studies on the use of secondary copper for the production of articles based on it, namely the contact wire for electric transport.

The effect of the drawing step on the macro- and microstructure and physical and mechanical properties of the copper wire was studied. The optimal draw pitch for continuous copper casting is 8.2 mm. At a temperature of the melt (casting) of 1200 °C and a draw step of 8.2 mm, the average crystallization rate is ~300 °C/s. This provides sufficient time for crystallization, and with such parameters, the heat transfer from the metal receiver does not have a noticeable effect on the structure. At the same time, it was established that Mg is a modifier for liquid Cu while all other elements do not have such an effect and form solid solutions with copper.

It is shown that the increase in the concentration of silver from 0.082 at% to 0.092 at% led to an increase in specific electrical resistance by 0.582 %. As for other elements, namely, iron, the change in its amount from 0.002 at% to 0.005 at% increased the specific resistance of copper by 1.733 %. The change in nickel concentration from 0.024 at% to 0.036 at% and tin from 0.0010 at% to 0.0035 at% led to its growth by 2.927 % and 1.269 %, respectively

References

- Sulitsin, A. V., Mysik, R. K., Brusnitsyn, S. V., Loginov, Yu. N. (2016). Nepreryvnoe lit'e medi. Ekaterinburg: Izd-vo UMTS ULI, 374.

- Beliy, D. I. (2011). Sovremennye tekhnologii proizvodstva mednoy katanki dlya kabel'noy promyshlennosti. Kabeli i provoda, 5, 29–33.

- Gorokhov, Yu. V., Belyaev, S. V., Uskov, I. V., Gubanov, I. Yu. (2014). Razvitie sovmeschennogo nepreryvnogo protsessa lit'ya i pressovaniya. Zhurnal Sibirskogo federal'nogo universiteta. Seriya: tekhnika i tekhnologii, 7 (4), 436–442.

- Raykov, Yu. N. (2003). Effektivnost' sovremennykh protsessov proizvodstva mednoy provolochnoy zagotovki. Izvestiya vuzov. Tsvetnaya metallurgiya, 3, 37–41.

- Efimov, V. A. (1991). Spetsial'nye sposoby lit'ya. Moscow: Mashinostroenie, 436.

- Vasilevsky, P. A., Zheleznyak, L. M., Ivanov, P. I., Emelyanova, S. M. (2012). Improvement of copper semi-finished billet manufacture for electrical engineering purposes. Metallurgist, 56 (3-4), 293–297. doi: https://doi.org/10.1007/s11015-012-9573-0

- Tavolzhanskii, S. A., Pashkov, I. N. (2021). Features of the Continuous Casting of Small-Section Billets from Copper-Based Alloys. Metallurgist, 64 (9-10), 1068–1076. doi: https://doi.org/10.1007/s11015-021-01088-y

- Mysik, R. K., Sulitsin, A. V., Morgunov, V. V. (2021). To the Question of the Manufacturing Ability a Contact Wire by Continuous Casting Rod. Solid State Phenomena, 316, 426–432. doi: https://doi.org/10.4028/www.scientific.net/ssp.316.426

- Ma, A., Zhu, C., Chen, J., Jiang, J., Song, D., Ni, S., He, Q. (2014). Grain Refinement and High-Performance of Equal-Channel Angular Pressed Cu-Mg Alloy for Electrical Contact Wire. Metals, 4 (4), 586–596. doi: https://doi.org/10.3390/met4040586

- Sulitsin, A. V., Mysik, R. K., Morgunov, V. V. (2021). Technology of the Contact Wire Manufacture for High-Speed Railways. Defect and Diffusion Forum, 410, 173–178. doi: https://doi.org/10.4028/www.scientific.net/ddf.410.173

- Marukovich, E. I., Demchenko, E. B. (2012). Yavleniya pri formirovanii nepreryvnoy otlivki. Minsk: BNTU, 208.

- Zemekov, I. V., Krutilin, A. N. (2015). Vertikal'noe nepreryvnoe lit'e zagotovok. Minsk: BNTU, 207.

- Smirnov, S. L. (2010). Formirovanie struktury i svoystv nepreryvnolitoy zagotovki iz medi v usloviyakh intensivnogo vneshnego okhlazhdeniya. Ekaterinburg, 23.

- Verkhovliuk, A. M., Petrovskyi, R. V., Babych, V. M. (2022). Vplyv Mg, Ag, Sn, Fe, Ni na strukturu ta vlastyvosti midnykh zahotovok. Lytvo. Metalurhiya. 2022: M-ly XVIII Mizhn. nuk.-prakt. kon-tsiyi. Kharkiv: NTU «KhPI», 36–39. Available at: https://nmetau.edu.ua/file/materiali_konferentsiyi_litvo._metalurgiya_-_2022.pdf

- Chervonyj, I. F., Petrovskij, R. V., Verhovlyuk, A. M. (2019). Production of continuously cast products made of alloys based on secondary copper. Scientific Look into the Future, 1 (13), 22–38. doi: https://doi.org/10.30888/2415-7538.2019-13-01-009

- Verkhovliuk, A. M., Petrovskyi, R. V., Chervonyi, I. F., Lachnenko, V. L. (2020). Influence of drawing speed on contact wire properties. Modern Scientific Researches, 14, 19–26.

- Verkhovliuk, A. M., Petrovskyi, R. V., Naumenko, M. I., Babych, V. M. (2021). Vplyv shahu vytiazhky na strukturu lytykh zahotovok na osnovi midi. M-ly XVII Mizhn. nuk.-prakt. kon-tsiyi. Zaporizhzhia, 35–38. Available at: https://nmetau.edu.ua/file/lite._metallurgiya._2021.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ruslan Petrovs'ky, Anatolii Verkhovliuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.