Identifying the influence of transient thermal tensioning treatments on minimizing distortion and improving fatigue behavior of steel welded

DOI:

https://doi.org/10.15587/1729-4061.2023.285192Keywords:

TTT treatment, distortion, fatigue behavior, flame heating, welding efficiency, welding process, steel welded, thin plates, microstructure, tensile strengthAbstract

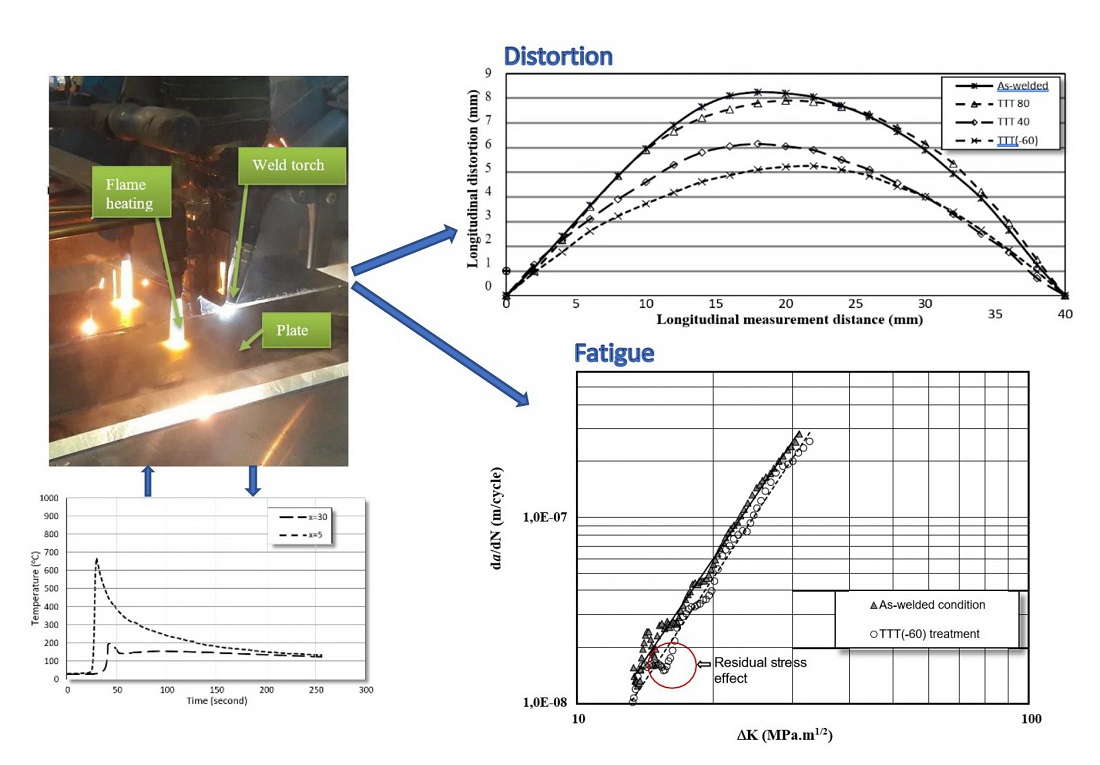

Due to the cost efficiency of welding repairs, the use of transient thermal tensioning (TTT) has begun to be applied to minimize distortion and residual stresses, particularly on thin plates. However, it requires a long preheating time especially on large structures, so that the efficiency of welding process cannot be maximized. Application of TTT treatment using flame heater on TTT treatment which require no preheating time so that welding efficiency can be increased. The aims of this study are to investigate the TTT treatment in reducing distortion, investigate the effect of TTT treatment on tensile strength and hardness, investigate the microstructure and its effect on tensile strength and hardness, investigated the effect of TTT treatment on fatigue crack growth rate. In this research, TTT treatment was performed by flame heating on the both side of weld line integrated in welding process. Temperature in both side plates were controlled and measured using thermocouple. The tests on the weld joints were carried out including distortion measurement, microstructure examination, hardness measurement, tensile test and fatigue test. Results showed that the TTT (60) treatment is the most effective in decreasing the longitudinal distortion which placing the flame heating a 60 mm behind welding torch. It tends to increase the tensile strength of weld metal supported by its increasing hardness. The increase in the percentage of the acicular ferrite phase is linearly related to the tensile strength and hardness of the weld joint. The fatigue behavior could be improved by TTT treatment (60) which is associated with the effect of decreasing residual stress in the weld metal region. This treatment is the best parameter in an effort to increase the welding efficiency of the TTT method

References

- Zhou, Q., Wang, Y., Choi, S.-K., Cao, L., Gao, Z. (2018). Robust optimization for reducing welding-induced angular distortion in fiber laser keyhole welding under process parameter uncertainty. Applied Thermal Engineering, 129, 893–906. doi: https://doi.org/10.1016/j.applthermaleng.2017.10.081

- Subeki, N., Jamasri, Ilman, M. N., Iswanto, P. T. (2017). The effect of heating temperature in static thermal tensioning (STT) welding on mechanical properties and fatigue crack propagation rate of FCAW in steel A 36. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.4968310

- Triyono, Sukanto, H., Muhayat, N., Sutiyono (2014). Effect of Stretching during Welding Process on the Weldability of Dissimillar Metals Resistance Spot Welded between Carbon Steel and Low Nickel Stainless Steel. Advanced Materials Research, 894, 206–211. doi: https://doi.org/10.4028/www.scientific.net/amr.894.206

- Xu, J., Chen, L., Ni, C. (2007). Effect of vibratory weld conditioning on the residual stresses and distortion in multipass girth-butt welded pipes. International Journal of Pressure Vessels and Piping, 84 (5), 298–303. doi: https://doi.org/10.1016/j.ijpvp.2006.11.004

- Singh, P. K., Patel, D., Prasad, S. B. (2016). Optimization of process parameters during vibratory welding technique using Taguchi’s analysis. Perspectives in Science, 8, 399–402. doi: https://doi.org/10.1016/j.pisc.2016.04.088

- Peng, K., Yang, C., Fan, C., Lin, S. (2018). Microstructure and mechanical properties of simulated unaltered coarse grained heat affected zones of 10CrNi3MoV steel by double-sided double arc welding. Journal of Materials Processing Technology, 251, 225–231. doi: https://doi.org/10.1016/j.jmatprotec.2017.08.032

- Takwim, R. N. A., Purwoko, P., Pranoto, B. (2021). Effect of Temperature Variation of Static Thermal Tensioning on Angular Distortion and Sensitization behavior of GMAW Welded SUS 304 Stainless Steel Plate. Logic: Jurnal Rancang Bangun Dan Teknologi, 21 (3), 218–224. doi: https://doi.org/10.31940/logic.v21i3.218-224

- Ilman, M. N., Sehono, Muslih, M. R., Wibowo, H. (2020). The application of transient thermal tensioning for improving fatigue crack growth resistance of AA5083-H116 FSW joints by varying secondary heating temperature. International Journal of Fatigue, 133, 105464. doi: https://doi.org/10.1016/j.ijfatigue.2019.105464

- Souto, J., Ares, E., Alegre, P. (2015). Procedure in Reduction of Distortion in Welding Process by High Temperature Thermal Transient Tensioning. Procedia Engineering, 132, 732–739. doi: https://doi.org/10.1016/j.proeng.2015.12.554

- Michaleris, P. (2011). Introduction to welding residual stress and distortion. Minimization of Welding Distortion and Buckling, 3–22. doi: https://doi.org/10.1533/9780857092908.1.3

- Tra, T. H., Okazaki, M., Suzuki, K. (2012). Fatigue crack propagation behavior in friction stir welding of AA6063-T5: Roles of residual stress and microstructure. International Journal of Fatigue, 43, 23–29. doi: https://doi.org/10.1016/j.ijfatigue.2012.02.003

- Zhang, Y., Ying, Y., Liu, X., Wei, H. (2016). Deformation control during the laser welding of a Ti6Al4V thin plate using a synchronous gas cooling method. Materials & Design, 90, 931–941. doi: https://doi.org/10.1016/j.matdes.2015.11.035

- Pazooki, A. M. A., Hermans, M. J. M., Richardson, I. M. (2016). Finite element simulation and experimental investigation of thermal tensioning during welding of DP600 steel. Science and Technology of Welding and Joining, 22 (1), 7–21. doi: https://doi.org/10.1080/13621718.2016.1180861

- Yi, B., Wang, J. (2022). Influence of Location of Transient Thermal Tensioning on Mitigating Buckling Distortion During Thin Plates Fillet Welding. The 32nd International Ocean and Polar Engineering Conference. Available at: http://publications.isope.org/proceedings/ISOPE/ISOPE%202022/data/pdfs_Vol4/414-TPC-0232.pdf

- Deo, M. V., Michaleris, P. (2003). Mitigation of welding induced buckling distortion using transient thermal tensioning. Science and Technology of Welding and Joining, 8 (1), 49–54. doi: https://doi.org/10.1179/136217103225008919

- Yang, Y. P., Dong, P. (2011). Buckling Distortions and Mitigation Techniques for Thin-Section Structures. Journal of Materials Engineering and Performance, 21 (2), 153–160. doi: https://doi.org/10.1007/s11665-011-9928-x

- Liu, Y., Ma, N., Lu, F., Fang, H. (2021). Measurement and analysis of welding deformation in arc welded lap joints of thin steel sheets with different material properties. Journal of Manufacturing Processes, 61, 507–517. doi: https://doi.org/10.1016/j.jmapro.2020.11.038

- Fahlström, K., Andersson, O., Karlsson, L., Svensson, L.-E. (2017). Metallurgical effects and distortions in laser welding of thin sheet steels with variations in strength. Science and Technology of Welding and Joining, 22 (7), 573–579. doi: https://doi.org/10.1080/13621718.2016.1275483

- Wen, Q., Ji, S., Zhang, L., Yue, Y., Lv, Z. (2018). Temperature, Stress and Distortion of Ti–6Al–4V Alloy Low-Temperature Friction Stir Welding Assisted by Trailing Intensive Cooling. Transactions of the Indian Institute of Metals, 71 (12), 3003–3009. doi: https://doi.org/10.1007/s12666-018-1401-1

- Li, J., Guan, Q., Shi, Y., Guo, D., Du, Y., Sun, Y. (2004). Studies on characteristics of temperature field during GTAW with a trailing heat sink for titanium sheet. Journal of Materials Processing Technology, 147 (3), 328–335. doi: https://doi.org/10.1016/j.jmatprotec.2003.12.012

- Ji, S., Yang, Z., Wen, Q., Yue, Y., Zhang, L. (2018). Effect of Trailing Intensive Cooling on Residual Stress and Welding Distortion of Friction Stir Welded 2060 Al-Li Alloy. High Temperature Materials and Processes, 37 (5), 397–403. doi: https://doi.org/10.1515/htmp-2016-0217

- Wibowo, H., Ilman, M. N., Iswanto, P. T., Muslih, M. R. (2017). Control of Distortion by Combined Effect of DC-LSND and TTT in MIG Weld Joints and Its Effect on Residual Stress and Fatigue Behavior. International Journal of Mechanical and Mechatronics Engineering, 17 (06).

- Smallman, R. E., Bishop, R. J. (1999). Modern Physical Metallurgy and Materials Engineering. Butterworth-Heinemann. doi: https://doi.org/10.1016/b978-0-7506-4564-5.x5000-9

- Digheche, K., Boumerzoug, Z., Diafi, M., Saadi, K. (2017). Influence of heat treatments on the microstructure of welded API X70 pipeline steel. Acta Metallurgica Slovaca, 23 (1), 72–78. doi: https://doi.org/10.12776/ams.v23i1.879

- Fattahi, M., Nabhani, N., Hosseini, M., Arabian, N., Rahimi, E. (2013). Effect of Ti-containing inclusions on the nucleation of acicular ferrite and mechanical properties of multipass weld metals. Micron, 45, 107–114. doi: https://doi.org/10.1016/j.micron.2012.11.004

- Nako, H., Miyamoto, G., Zhang, Y., Furuhara, T. (2022). Influence of Acicular Ferrite Microstructure on Toughness of Ti-Rare Earth Metal (REM)-Zr Killed Steel. Tetsu-to-Hagane, 108 (5), 295–305. doi: https://doi.org/10.2355/tetsutohagane.tetsu-2021-127

- Dhib, Z., Guermazi, N., Gaspérini, M., Haddar, N. (2016). Cladding of low-carbon steel to austenitic stainless steel by hot-roll bonding: Microstructure and mechanical properties before and after welding. Materials Science and Engineering: A, 656, 130–141. doi: https://doi.org/10.1016/j.msea.2015.12.088

- Sun, Q., Di, H.-S., Li, J.-C., Wu, B.-Q., Misra, R. D. K. (2016). A comparative study of the microstructure and properties of 800 MPa microalloyed C-Mn steel welded joints by laser and gas metal arc welding. Materials Science and Engineering: A, 669, 150–158. doi: https://doi.org/10.1016/j.msea.2016.05.079

- D’Urso, G., Giardini, C., Lorenzi, S., Pastore, T. (2014). Fatigue crack growth in the welding nugget of FSW joints of a 6060 aluminum alloy. Journal of Materials Processing Technology, 214 (10), 2075–2084. doi: https://doi.org/10.1016/j.jmatprotec.2014.01.013

- Kumar, M., Bhadauria, S. S., Sharma, V. (2022). Effect of tool pin profiles on fatigue crack growth rate of friction stir welded joint of Al alloy 7075-T651. Canadian Metallurgical Quarterly, 1–10. doi: https://doi.org/10.1080/00084433.2022.2160574

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Heri Wibowo, Fredy Surahmanto, Mochammad Noer Ilman

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.