Визначення особливостей процесу тепломасопереносу у вертикальних кабельних тунелях атомної електричної станції за умов реальних пожеж

DOI:

https://doi.org/10.15587/1729-4061.2023.289291Ключові слова:

натурні вогневі випробування, атомна електрична станція, вертикальний кабельний тунель, температурний режим пожежіАнотація

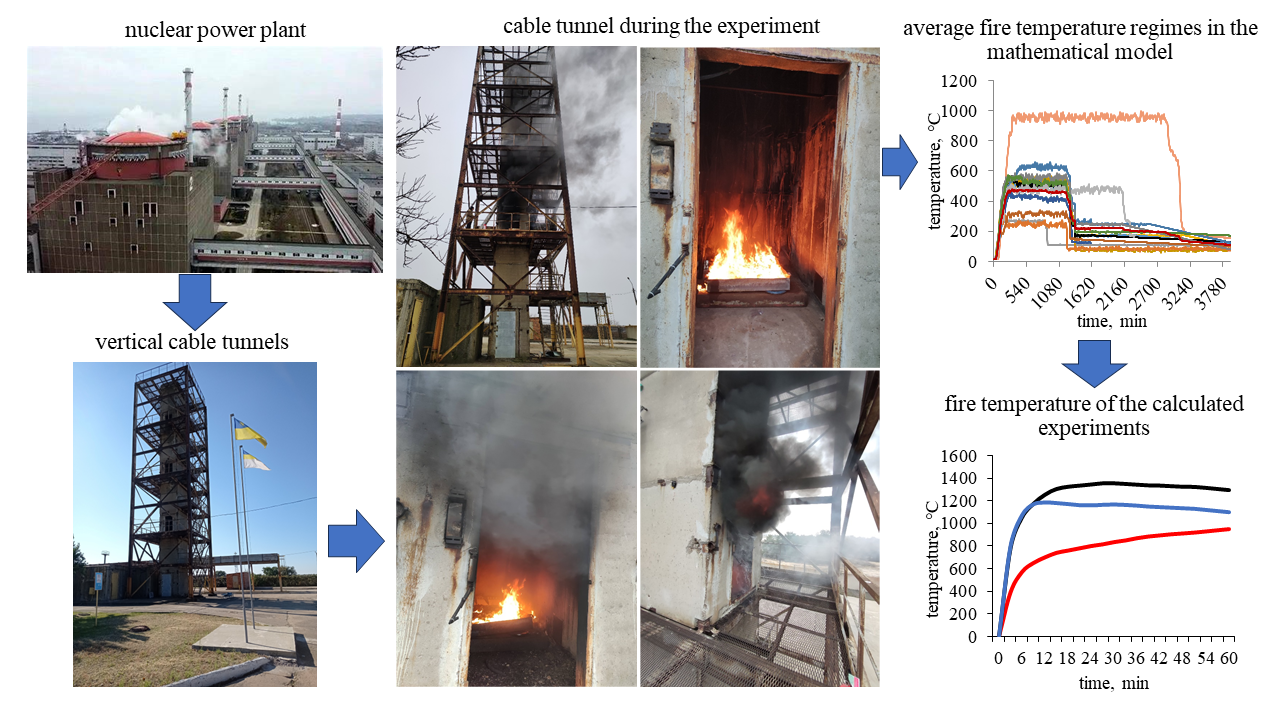

Об’єктом дослідження були процеси тепломасопереносу, що виникають у вертикальних кабельних тунелях. Проблема, що вирішувалася, – визначення механізмів процесу у внутрішньому просторі тунелю. Для цього проводилися натурні випробування, створювалися математичні моделі та проводилися обчислювальні експерименти з встановленням конкретних параметрів, які впливають на температурний режим пожежі у вертикальному кабельному тунелі атомної електростанції. Визначена динаміка зміни температури з відомими геометричними параметрами й пожежним навантаженням та досліджено адекватність математичних моделей побудованих у програмному забезпеченні Fire Dynamics Simulator та проведення обчислювальних експериментів. Доведено, що вони полягають у визначенні температурного режиму у вертикальному кабельному тунелі атомної електростанції із відомими технічними та геометричними параметрами. Такі дослідження мають практичне застосування в галузі безпеки атомних електростанцій та розробки нових технологій у цій галузі. Важливим висновком цих досліджень є можливість визначення вогнестійкості будівельних конструкцій вертикальних кабельних тунелів атомних електростанцій з обранням найжорсткішого температурного режиму, відповідно до проведеного натурного випробування. Це означає, що результати досліджень можуть бути використані на практиці при проектуванні та оцінці безпеки таких об’єктів.

Проведеним дослідженням встановлено, що температура у внутрішньому просторі тунелю може досягати значень від 1200 до 1400 ℃. Вплив на максимальне значення температури та максимальний час досягнення максимальної температури в осередку пожежі мають наступні фактори: пожежне навантаження, висота та площа тунелю. При меншому пожежному навантаженні максимальна температура у вертикальному кабельному тунелі атомної електростанції була на 75 % нижчою. Отже, результати цих досліджень мають безпосереднє застосування на практиці в галузі безпеки атомних електростанцій і можуть бути використані для покращення та розробки нових технологій у цій галузі

Посилання

- International Atomic Energy Agency. Fire Safety in the Operation of Nuclear Power Plants, IAEA Safety Standards Series No. NS-G-2.1, IAEA (2000). Vienna. Available at: https://www.iaea.org/publications/6018/fire-safety-in-the-operation-of-nuclear-power-plants

- UNE EN 1991-1-2:2019. Eurocode 1: Actions on structures - Part 1-2: General actions - Actions on structures exposed to fire. Available at: https://www.en-standard.eu/une-en-1991-1-2-2019-eurocode-1-actions-on-structures-part-1-2-general-actions-actions-on-structures-exposed-to-fire/?gclid=EAIaIQobChMI7PTbgLL_gQMVRFuRBR08ewG3EAAYASAAEgKBcfD_BwE

- EN 1992-1-2 (2004) (English): Eurocode 2: Design of concrete structures - Part 1-2: General rules - Structural fire design. Available at: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1992.1.2.2004.pdf

- VII.4 Fire resistance of structures. Available at: https://tunnelsmanual.piarc.org/sites/tunnels-manual/files/public/wysiwyg/import/Chapters%20PIARC%20reports/1999%2005.05.B%20Chap%207.4%20EN.pdf

- Kovalyshyn, V. V. (2013). Perevirka na adekvatnist modeliuvannia protsesiv rozvytku i hasinnia pozhezh v kabelnykh tuneliakh (v obmezhenykh obiemakh). Naukovyi visnyk Ukrainskoho naukovo-doslidnoho instytutu pozhezhnoi bezpeky, 1 (27), 38–44.

- Ji, J., Bi, Y., Venkatasubbaiah, K., Li, K. (2016). Influence of aspect ratio of tunnel on smoke temperature distribution under ceiling in near field of fire source. Applied Thermal Engineering, 106, 1094–1102. doi: https://doi.org/10.1016/j.applthermaleng.2016.06.086

- Tian, X., Zhong, M., Shi, C., Zhang, P., Liu, C. (2017). Full-scale tunnel fire experimental study of fire-induced smoke temperature profiles with methanol-gasoline blends. Applied Thermal Engineering, 116, 233–243. doi: https://doi.org/10.1016/j.applthermaleng.2017.01.099

- Modic, J. (2003). Fire simulation in road tunnels. Tunnelling and Underground Space Technology, 18 (5), 525–530. doi: https://doi.org/10.1016/s0886-7798(03)00069-5

- Vaari, J. et al. (2012). Numerical simulations on the performance of waterbased fire suppressions systems. VTT Technology, 54. Available at: https://publications.vtt.fi/pdf/technology/2012/T54.pdf

- Sun, J., Fang, Z., Tang, Z., Beji, T., Merci, B. (2016). Experimental study of the effectiveness of a water system in blocking fire-induced smoke and heat in reduced-scale tunnel tests. Tunnelling and Underground Space Technology, 56, 34–44. doi: https://doi.org/10.1016/j.tust.2016.02.005

- Zhang, P., Tang, X., Tian, X., Liu, C., Zhong, M. (2016). Experimental study on the interaction between fire and water mist in long and narrow spaces. Applied Thermal Engineering, 94, 706–714. doi: https://doi.org/10.1016/j.applthermaleng.2015.10.110

- Troshkin, S. E., Sidney, S. A., Tischenko, E. A., Nekora, O. V. (2015). Issledovanie adekvatnosti rezul'tatov matematicheskogo modelirovaniya dinamiki pozhara v pomeschenii s pomosch'yu programmnogo kompleksa FDS. Pozharnaya bezopasnost': teoriya i praktika, 20, 104–109.

- Forney, G. P. (2007). User‘s Guide for Smokeview Version 5-A Tool for Visualizing Fire Dynamics Simulation Data. NIST Special Publication 1017-1. Available at: https://nvlpubs.nist.gov/nistpubs/SpecialPublications/NIST.SP.1017-1.pdf

- Yelahin, H. I., Yelahin, H. I., Shkarabura, M. H., Kryshtal, M. A., Tyshchenko, O. M. (2013). Osnovy teoriyi rozvytku i prypynennia horinnia. Cherkasy: Akademiya pozhezhnoi bezpeky imeni Heroiv Chornobylia, 460.

- Nuianzin, O. M., Nekora, O. V., Pozdieiev, S. V. et al. (2019). Metody matematychnoho modeliuvannia teplovykh protsesiv pry vyprobuvanniakh na vohnestiykist zalizobetonnykh budivelnykh konstruktsiy. Cherkasy: ChIPB im. Heroiv Chornobylia NUTsZ Ukrainy, 120.

- Kaptsov, I. I. et al. (2009). Metodychni vkazivky do naukovo-doslidnytskoi praktyky z dystsypliny «Orhanizatsiya naukovykh doslidzhen» (Statystychni metody. Analiz ta oformlennia naukovykh doslidzhen). Kharkiv: KhNAMH, 59.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Serhii Troshkin, Oleh Kulitsa, Serhii Pozdieiev, Tetiana Kostenko, Oleh Zemlianskyi, Nataliia Zaika

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.